The Critical Role of Grout in Your Fireplace’s Safety and Style

Fireplace grout is the specialized mortar used to fill the joints between the stones, bricks, or tiles of your fireplace. It’s critical for both safety and style, preventing heat damage and keeping your fireplace structurally sound. Using the wrong grout can lead to rapid deterioration and safety hazards.

Quick Answer: What to Look for in Fireplace Grout

- Heat Resistance: Must withstand temperatures of 2,000°F or higher.

- Material Type: Use refractory mortar for the firebox and Type N or S mortar for the surround.

- Key Ingredients: Look for fireclay, calcium aluminate, or high-alumina cement.

- Application: Proper mixing, joint preparation, and curing are essential.

Standard tile grout will crack and crumble under fireplace conditions because it lacks the necessary refractory properties. Heat-resistant grouts are specifically formulated with materials like fireclay that won’t break down when exposed to high temperatures.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years of experience, I’ve repaired countless fireplaces damaged by improper fireplace grout selection. Our masonry team specializes in ensuring your fireplace is both safe and beautiful.

The Ultimate Guide to Fireplace Grout Selection and Application

When it comes to your fireplace, the intense heat and constant expansion and contraction demand a material that can stand up to the challenge. Let’s explore how to select and apply the perfect fireplace grout.

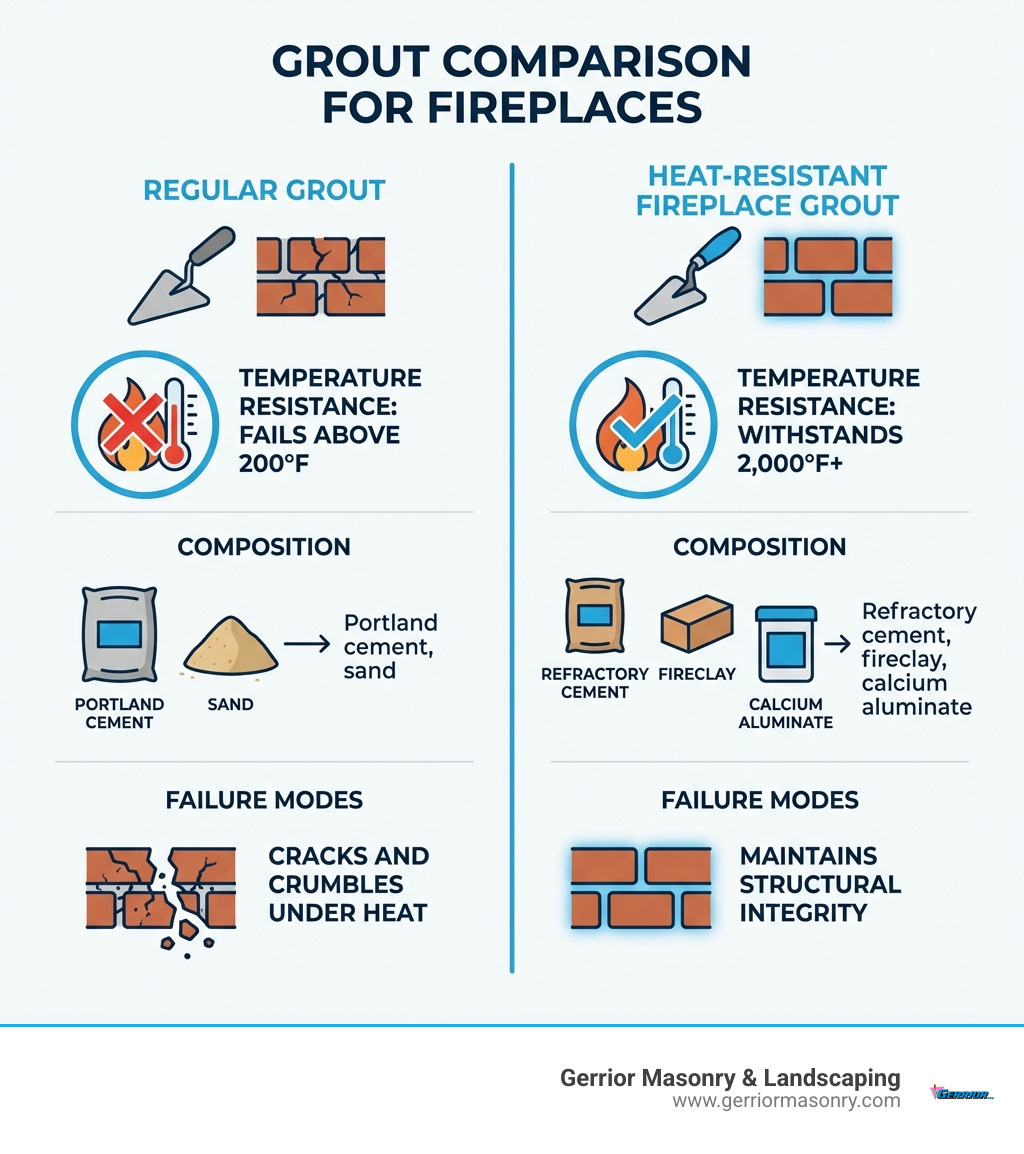

Heat-Resistant vs. Regular Grout: A Crucial Distinction

The most critical factor for fireplace grout is its ability to withstand high temperatures. Standard grout, used for bathroom tiles, is typically made from Portland cement and sand. It cannot handle the extreme heat of a fireplace and will quickly crack and crumble, creating a serious safety hazard.

Heat-resistant grout, also called refractory mortar, is engineered for high-temperature applications. Its composition includes specialized materials:

- Fireclay: A natural clay that withstands extreme heat.

- Calcium Aluminate Cement: A high-performance cement that maintains strength at high temperatures.

These ingredients allow refractory grouts to endure temperatures over 2,000°F, while regular grout often fails above 200°F. Using regular grout in a fireplace can lead to cracking, fire hazards from escaping embers, and aesthetic ruin. Always choose products labeled “heat-resistant” or “refractory” for any part of your fireplace exposed to significant heat. For more details on materials designed for extreme heat, see our guide on heat resistant cement.

Types of Grout for Different Fireplace Materials (Stone, Brick, Tile)

The type of fireplace grout also depends on where it’s applied, as different zones of a fireplace experience varying levels of heat.

-

For the Firebox (Inner Chamber): This is the hottest area. Refractory Mortar is the only acceptable material. It is a type of heat-resistant cement containing fireclay, designed to withstand direct flame contact and temperatures over 2,000°F.

-

For the Surround and Hearth (Exterior): These areas get hot but don’t have direct flame contact.

- Natural Stone & Brick: A Type N or Type S masonry mortar is the standard choice. Type N is a general-purpose mortar, while Type S offers higher strength. For a lighter color to complement stone, mix white masonry cement with fine sand (3 parts sand to 1 part cement).

- Tile (Ceramic, Porcelain, etc.): Use a cement-based grout specifically labeled as “heat-resistant tile grout.” For areas where the hearth meets another material like a wood floor, a flexible, heat-resistant grout or caulk is necessary to prevent cracking from movement.

Here’s a quick comparison of grout/mortar types for common fireplace materials:

| Fireplace Area/Material | Recommended Grout/Mortar Type | Key Characteristics |

|---|---|---|

| Firebox (Inner) | Refractory Mortar / Fireclay | Withstands direct flame and extreme heat (2,000°F+). Crucial for safety and structural integrity of the firebox. |

| Stone Surround/Veneer | Type N or S Masonry Mortar | Good for aesthetics and durability in areas not exposed to direct flame. Can be colored with dyes. If using white cement, mix 3 parts sand to 1 part white cement for a lighter shade. |

| Brick Surround/Hearth | Type N or S Masonry Mortar | Strong, durable, and compatible with brick. Choose color carefully. |

| Tile Surround/Hearth | Heat-Resistant Tile Grout | Specifically formulated for high-temperature tile applications. May include flexible properties. Ensure it’s rated for fireplace use. Epoxy grouts offer stain resistance for exteriors, provided they can handle the heat. |

Preparation and Mixing for a Professional Result

Proper preparation and mixing are essential for a durable, professional fireplace grout finish.

Preparation Steps:

- Clean Joints: Use a wire brush and chisel to remove all old, loose grout, dust, and debris. A clean joint is paramount for a strong, lasting bond. Any remaining dust or loose material will compromise the new grout’s adhesion, leading to premature cracking and failure. A shop vacuum can be very effective for removing fine dust after brushing and chiseling.

- Ensure Stability: Make sure all stones, bricks, or tiles are firmly set and anchored before grouting. Before applying new grout, test each stone or brick for movement. If any are loose, they must be reset with the appropriate mortar first. Grouting over unstable masonry is a temporary fix that will fail as the units shift.

- Protect Surfaces: Use masking tape to protect adjacent surfaces like the mantel or flooring.

- Pre-Wet Porous Materials: Thoroughly saturate porous stone or brick with water using a sprayer. This prevents the material from drawing moisture out of the grout too quickly, which helps prevent staining and ensures a stronger bond. This step, known as achieving a ‘Saturated Surface Dry’ (SSD) condition, is especially critical for natural stone. It ensures the grout cures slowly and evenly, maximizing its strength. If the stone is too dry, it will wick essential moisture from the grout mix, resulting in a weak, crumbly joint.

Tools Needed:

- 5-gallon bucket

- Heavy-duty drill with a paddle mixer

- Grout bag or margin trowel/grout float

- Jointing tool

- Stiff masonry brush and grout sponge

- Safety gear (gloves, eye protection, dust mask)

How to Mix Fireplace Grout:

- Follow Instructions: Always read the manufacturer’s instructions on the bag for specific water-to-mix ratios.

- Mix to Consistency: Add water gradually to the dry mix while blending with a paddle mixer. Aim for a thick, smooth consistency like peanut butter—stiff enough to hold its shape but wet enough to be workable.

- Let it Slake: After the initial mix, let the grout rest for 5-10 minutes. This process, called slaking, allows the water to fully activate the cement. Give it a final quick mix before application.

How to Properly Apply Fireplace Grout

With your grout mixed, it’s time for application. The best technique depends on your fireplace material.

1. Grout Bag Method (For Stone or Irregular Joints):

This method offers precise application for deep or varied joints, minimizing mess on the stone face.

- Fill and Pipe: Fill the grout bag two-thirds full. Snip the tip to match your joint width and squeeze the grout deep into the joints, working from the bottom up. Overfill the joints slightly.

- Tooling: After the grout stiffens to a “crumbly” texture (usually within an hour), use a jointing tool or putty knife to press and shape the grout to your desired profile. This compacts the grout and creates a clean finish.

2. Trowel and Float Method (For Tile or Uniform Joints):

This classic method is ideal for evenly spaced tile or brick.

- Spread Grout: Using a rubber grout float held at a 45-degree angle, spread the grout across the surface, pressing it firmly into the joints.

- Remove Excess: Hold the float at a near 90-degree angle and scrape off excess grout from the surface. Move diagonally across the joints to avoid pulling out the freshly applied grout.

For more detailed guidance on repairing fireplace mortar, visit our page on fireplace mortar repair.

Cleaning, Curing, and Troubleshooting Common Issues

The final steps of cleaning and curing are crucial for a lasting, professional look.

How to Clean Excess Grout:

- For Tile/Brick: About 15-30 minutes after application, use a damp (not wet) grout sponge to gently clean the surfaces. Rinse the sponge frequently in clean water.

- For Stone Veneer: To avoid staining porous stone, let any excess grout on the stone face dry for 1-2 hours. Then, use a stiff masonry brush or dry cloth to brush it off.

- Haze Removal: A faint haze may appear after drying. This can often be removed by scrubbing with a 1:1 solution of white vinegar and water, followed by a clean water rinse. Avoid using muriatic acid, as it can damage masonry.

Drying and Curing Times:

- Drying: Grout is typically dry to the touch within 24 hours.

- Curing: Full strength is achieved after a complete curing period, which can take 7 to 28 days. Avoid using the fireplace during this time.

Common Grouting Problems and Fixes:

- Cracking: Caused by an improper mix, movement, or using non-heat-resistant grout. The only fix is to carefully remove the cracked section and reapply new, appropriate grout.

- Staining: Caused by grout pigments absorbing into porous stone. Prevent this by pre-wetting surfaces before grouting and cleaning carefully.

- Shrinking: Caused by too much water in the mix. Prevent this by mixing to a proper “peanut butter” consistency. Minor gaps can be refilled, but significant shrinkage requires reapplication.

For a visual guide, check out this helpful guide on grouting stone from Old World Stoneworks.

Advanced Techniques: Overgrouting and Caulking

Two techniques can improve the look and durability of your fireplace.

What is ‘Overgrouting’?

Overgrouting is a stylistic choice where grout is applied liberally to extend over the edges of the stone or brick. This creates a soft, organic, “old-world” look, often called a “German schmear.” Instead of clean, recessed joint lines, overgrouting blurs the edges for a more monolithic, textured appearance.

This DIY overgrouting tutorial offers great tips for achieving this popular style.

Grouting vs. Caulking for Hearth Joints

It’s critical to know when to use grout versus caulk, especially where your hearth meets another material like a wood floor.

- Grout is a rigid, cement-based filler for static joints between masonry units (stone-to-stone, brick-to-brick).

- Caulk is a flexible sealant used for joints that experience movement. Use heat-resistant caulk for any expansion joint where the fireplace hearth meets a different material, such as a wood floor or drywall. Wood expands and contracts with humidity changes; rigid grout in this joint will crack. Many manufacturers offer color-matched caulk to create a seamless look between grouted and caulked joints.

When to Call the Pros for Your Fireplace Project

While minor fireplace grout repairs can be a DIY task, some situations require professional expertise for safety and quality. At Gerrior Masonry & Landscape Construction Corp., we recommend calling a professional for the following:

- Significant Structural Damage: Large cracks in the firebox, crumbling load-bearing mortar, or any signs of instability are serious safety concerns that go beyond cosmetic repair. We specialize in comprehensive chimney mortar repair and can fix underlying structural problems.

- Large-Scale Repointing: If most of the mortar joints are failing, the fireplace needs to be repointed. This is a labor-intensive job requiring skill to ensure a proper bond and consistent appearance. Our masons are experts in tuckpointing vs repointing.

- Water Damage: Persistent dampness, stains, or white powdery residue (efflorescence) point to a water leak. A professional can find and fix the source, which is essential before making any cosmetic repairs.

- Code Compliance and Historic Restoration: Professionals ensure your fireplace meets all safety and building codes. For historic homes, we use appropriate materials and techniques to preserve the original character.

- Guaranteed Craftsmanship: For a flawless finish and peace of mind, hiring an experienced team is the best choice. We handle everything from material selection to cleanup, ensuring a beautiful and safe result.

If you are unsure about the scope of your project or want the assurance of expert service, don’t hesitate to reach out. For professional fireplace mortar repair, contact our team. Gerrior Masonry & Landscape Construction is based in Woburn, MA, and proudly services Middlesex and Essex County, Massachusetts.