Base for Retaining Wall: 7 Proven Steps for Perfect Results 2025

Why Your Retaining Wall’s Foundation Determines Its Fate

A proper base for retaining wall construction is the difference between a wall that lasts decades and one that fails within a few seasons. As one professional noted, “even 1-2 inches of loose soil can cause the wall to settle and fail.”

Quick Answer for Base for Retaining Wall Requirements:

– Trench depth: 6 inches + 1 inch per foot of wall height

– Trench width: 24 inches (18 inches for walls under 4 feet)

– Base material: 6 inches minimum of compacted ¾-inch crushed stone

– Drainage: Perforated pipe required for walls over 4 feet

– Embedment: Bury at least half the first block (full block for walls over 3 feet)

The base does three critical jobs: it distributes the wall’s weight evenly, prevents sliding, and stops water from undermining the foundation. Most retaining wall failures happen because of poor base preparation – not because the blocks themselves failed.

I’m Joe Gerrior, and over 34 years of building retaining walls in Massachusetts, I’ve seen how a properly prepared base for retaining wall projects can mean the difference between a $5,000 repair and a wall that stands strong through decades of New England freeze-thaw cycles.

Basic base for retaining wall vocab:

– perforated drain pipe retaining wall

– retaining wall drain pipe installation

– retaining wall with french drain

Why the Base Matters: The Science Behind Retaining Wall Stability

Your retaining wall faces constant pressure from soil behind it – a modest four-foot wall can face pressure from 20 tons of saturated earth. When you add water, those forces can double or triple. The force is greatest at the bottom where your base sits, which is why the foundation must be rock-solid.

Latest research on retaining-wall engineering shows walls with properly prepared bases last 300% longer than those built on unprepared soil. That’s the difference between a 10-year wall and a 40-year wall.

Hydrostatic pressure occurs when water builds up behind your wall, acting like a hydraulic jack. A good base with proper drainage gives that water somewhere to go. Freeze-thaw cycles create forces that can crack concrete, but a well-draining base prevents water from pooling and freezing where it can do damage.

What does the base actually do?

Your base for retaining wall works as a three-part system:

Load distribution works like snowshoes, spreading your wall’s weight over a larger area instead of letting it punch through soft spots in the soil.

Shear key resistance comes from burying half or more of the first course, creating an anchor against horizontal sliding forces.

Overturning resistance uses a wide, well-compacted base to create a stable platform that fights tipping forces. We make the base at least twice as wide as the blocks for good reason.

Why proper compaction prevents failure

Even two inches of loose soil can spell disaster. When that soil compresses under load, your perfectly level wall suddenly isn’t level anymore. We use a plate compactor to create artificial bedrock through vibrations that rearrange crushed stone particles into a tight, interlocking matrix.

The magic number is three passes minimum with a walk-behind plate compactor. This achieves 95% of maximum density, creating a base that rivals concrete for stability but drains like a sieve.

Determining Trench Width & Depth for the Perfect Base for Retaining Wall

For trench depth, use 6 inches plus 1 inch for every foot of wall height. A 4-foot wall needs a 10-inch deep trench (6 + 4 = 10). This provides room for your 6-inch base for retaining wall material plus depth to properly bury your first course.

Trench width should be 24 inches for most walls, though 18 inches works for walls under 4 feet. You need space for blocks, plus at least 8 inches behind them for drainage stone and room to operate your compactor.

In Massachusetts, ground can freeze 3-4 feet down, so permanent walls need deeper footings to prevent frost heave. Walls over 4 feet typically require building permits and may need an engineer’s stamp.

Retaining Wall Repair Near Me – unfortunately, many repairs start with fixing walls that had inadequate base preparation.

Quick sizing chart for gravity & reinforced walls

For gravity walls under 4 feet: 4-inch base depth plus 1 inch per foot of height, 18-inch wide trench, 6 inches of compacted crushed stone. Bury half the first block height.

For reinforced walls 4 feet and taller: 6 inches plus 1 inch per foot for depth, 24-inch wide trench, 6-8 inches of compacted stone. Bury the entire first block and add geogrid reinforcement.

Special conditions require adjustments. In clay soils, add 2-4 inches to depth and replace clay with granular material. On slopes, step the trench but maintain consistent embedment.

How much of the first course should be buried?

For walls 3 feet and under, bury at least half the height of your first block. For walls over 3 feet, bury the entire first course. This buried portion acts as an anchor against soil pressure. Walls that don’t have adequate embedment start leaning forward within a year or two.

Choosing the Right Base Material

The gold standard for retaining wall bases is ¾-inch angular crushed stone. The angular shape creates sharp edges that lock together when compacted, forming a stable foundation that won’t shift under pressure while maintaining excellent drainage.

We always install geotextile fabric underneath the stone base to prevent fine soil particles from migrating up and clogging your drainage system. Proper compaction happens in 2-inch lifts using a plate compactor, with each lift getting at least three passes.

Wall rock vs pea gravel vs sand

Crushed stone with angular shape provides superior interlock when compacted. Sharp edges grab onto each other, creating a stable matrix that won’t shift. Permeability is excellent and void ratio sits at 15-20% when properly compacted.

Pea gravel has smooth, rounded stones that roll over each other like marbles instead of locking together. We’ve seen too many failed walls where builders chose pea gravel because it was cheaper.

Sand creates poor drainage and can trap water, creating hydrostatic pressure. Even coarse sand lacks structural integrity needed for loaded retaining walls.

When is a concrete footing required?

Mortared stone or brick walls absolutely need concrete footings. These rigid systems have no tolerance for settlement.

Frost line considerations become critical in Massachusetts. Permanent walls often need concrete footings extending below the 3-4 foot frost line to prevent heaving.

Engineered walls over 4 feet high typically specify concrete footings in their structural calculations for predictable bearing capacity.

Poor soil conditions like soft clay or organic soil may require concrete footings even for smaller walls.

Step-by-Step Installation: From Soil Preparation to First Course

Call 811 (Dig Safe) at least 72 hours before excavating. Mark your wall location and excavate to your calculated depth, keeping the trench bottom level. Remove all organic material – leaves, roots, old mulch – anything that will decompose.

Subgrade preparation: Compact the trench bottom with a hand tamper or plate compactor until firm. If you hit soft clay or organic soil, over-excavate by 6-12 inches and replace with granular material.

Geotextile fabric installation: Roll it across the trench bottom and up the sides, overlapping seams by 6 inches. This prevents soil particles from migrating into your stone base.

Base material installation: Place crushed stone in 2-3 inch lifts maximum. Each lift must be compacted before adding the next. Use a walk-behind plate compactor with at least three passes over each area. Check for level frequently.

How to keep the base for retaining wall perfectly level

For longer walls, a rotary laser level provides a perfectly straight reference line. For shorter walls, the string line method works well – stretch taut string between stakes at proper elevation.

Use a screed method for final leveling – a straight 2×4 to screed the stone surface level. Don’t forget torpedo level checks every few feet, especially on curved walls.

Installing drainage pipe correctly

Place 4-inch perforated pipe at the back of the trench on 2-3 inches of base stone. Holes should face down, not up. Maintain proper slope – at least 1% grade (1 inch drop per 100 feet).

Always wrap the pipe in filter fabric and surround with clean stone. For our perforated drain pipe retaining wall installations, we ensure the pipe daylights to a safe outlet area.

How much to compact each lift of base for retaining wall

Keep lifts thin – never exceed 3 inches. Make multiple passes – three minimum. The stone should be slightly damp for best compaction. Your final compacted base for retaining wall should be firm enough that you can’t push a screwdriver into it by hand.

Adapting the Base to Challenging Conditions

Perfect building sites are rare. With the right approach, you can create a rock-solid base for retaining wall construction even in challenging conditions.

Preparing a base on clay or previously excavated fill

Clay soils hold water like a sponge, creating hydrostatic pressure. Over-excavate by 12-18 inches below your calculated depth and replace with granular material. Install geotextile fabric between clay and replacement stone.

Previously excavated fill looks solid until it starts settling. Never trust old fill – over-excavate until you hit undisturbed soil, then build back up with properly compacted granular material in 6-inch lifts.

Transitioning the base for retaining wall on step-ups

For our build a retaining wall on a slope projects, we use the “stair-step method.” Excavate your trench in level steps, with each step being exactly one block height. Never slope the base itself – it should be perfectly level within each step.

Special requirements for reinforced vs gravity block systems

Gravity block systems under 4 feet rely on block weight and setback for stability. Reinforced systems for walls over 4 feet use geogrid reinforcement extending into backfill, requiring wider bearing areas and often deeper bases. Segmental retaining wall (SRW) systems often have specific manufacturer requirements – follow the specs exactly.

Common Pitfalls, Safety, and Tools for a Fool-Proof Foundation

Most failures happen because someone tried to cut corners on base for retaining wall preparation. Under-compaction is the biggest culprit – thinking you can get away with a hand tamper instead of proper plate compaction. Wrong aggregate choices come second – pea gravel or sand instead of angular crushed stone.

Drainage disasters happen when people think small walls don’t need drainage. Every wall over 18 inches needs proper drainage. Frost heave destroys walls when frost depth isn’t considered. Skipping utility locate by not calling Dig Safe isn’t just expensive – it can be deadly.

Our stonework repairs often start with completely rebuilding the base because someone tried to save $500 in materials, turning into $5,000+ reconstruction projects.

Essential tools checklist

Rent a walk-behind plate compactor – don’t attempt this with just a hand tamper. Your laser level or 4-foot level keeps everything aligned. A rubber mallet fine-tunes block placement, while a steel rake spreads base stone evenly.

Safety basics include safety glasses, work gloves, and steel-toed boots. A trenching shovel makes precise excavation easier. For larger projects, consider renting a mini excavator.

Safety precautions during excavation

Call 811 (Dig Safe) at least 72 hours before digging – it’s the law in Massachusetts. Never work alone in trenches deeper than 4 feet. Keep excavated soil at least 2 feet back from the trench edge.

Watch for soil cracking or water seepage – these indicate unstable conditions requiring immediate evacuation. Trench collapse can happen in seconds, especially after heavy rains or during spring thaw.

Frequently Asked Questions about Base for Retaining Wall

What happens if I skip the compaction step?

Skipping compaction is like building on quicksand. Uncompacted base material will settle unevenly, causing blocks to separate, lean, or topple. We’ve seen walls fail within a single winter because the base wasn’t properly compacted. The cost of renting a plate compactor ($40-80) is nothing compared to rebuilding a failed wall ($3,000-15,000+).

Can I use sand or soil as the base?

Using sand or soil as your base for retaining wall is a recipe for failure. Sand doesn’t drain well, lacks interlocking properties, and can wash out. Soil contains organic matter that decomposes, clay that expands/contracts, and provides poor drainage. Stick with ¾-inch angular crushed stone.

Do small garden walls need a drainage pipe?

Yes, even small walls need proper drainage. Water is the enemy of all retaining walls, regardless of size. For walls under 3 feet, minimum gravel backfill is required, but perforated pipe is better. For walls 3+ feet, perforated drainage pipe is mandatory.

Conclusion

Building the perfect base for retaining wall construction requires understanding the science behind load distribution, sliding prevention, and water management.

Key takeaways:

– Never compromise on base width and depth – follow the 6-inch plus 1-inch per foot rule

– Use only ¾-inch angular crushed stone – it’s worth the extra cost

– Compact in thin lifts – make multiple passes with proper equipment

– Include drainage from the start – prevents 90% of wall failures

– Bury adequate block height – half for low walls, full block for walls over 3 feet

Walls over 4 feet typically require engineering and permits. Complex sites may need professional design regardless of height.

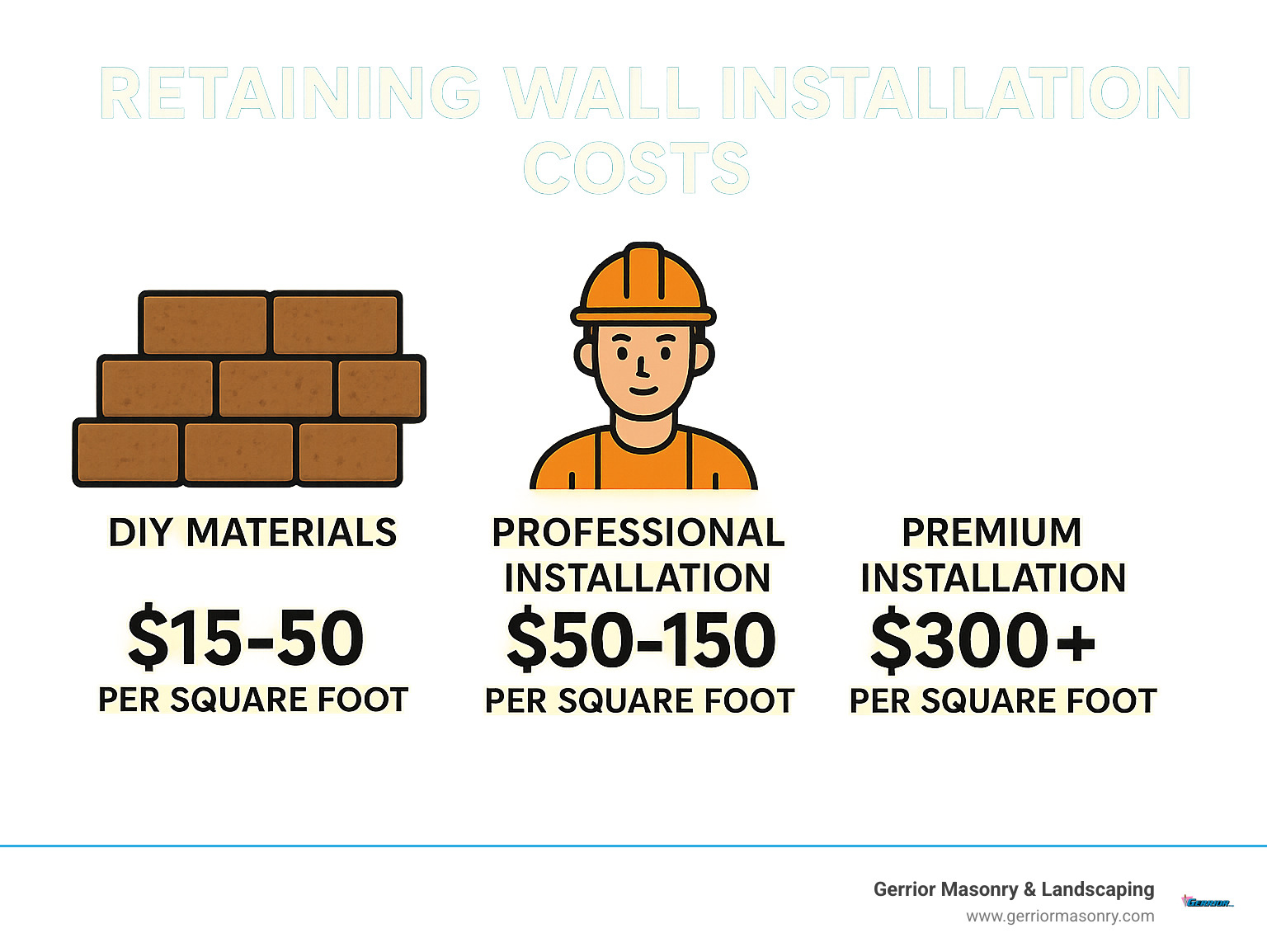

Average costs for retaining wall installation based on internet data range from $15-50 per square foot for DIY materials, $50-150 per square foot for professional installation, with premium installations reaching $300+ per square foot. These are average costs based on internet data and not actual costs for Gerrior Masonry services.

At Gerrior Masonry & Landscaping, we’ve spent over 30 years perfecting retaining wall construction throughout Massachusetts. Our skilled team provides owner oversight on every project, ensuring your wall will stand strong through decades of New England weather. For more information about our custom retaining walls and professional installation services, we’re here to help.

Whether you’re building a small garden terrace or a major landscape feature, investing in proper base preparation will pay dividends for decades to come. Your retaining wall is only as strong as its foundation – make sure yours is built to last.

Gerrior Masonry & Landscape Construction is based in Woburn, MA, and services Middlesex and Essex County, Massachusetts.