Why Concrete Patio Construction Matters for Your Home

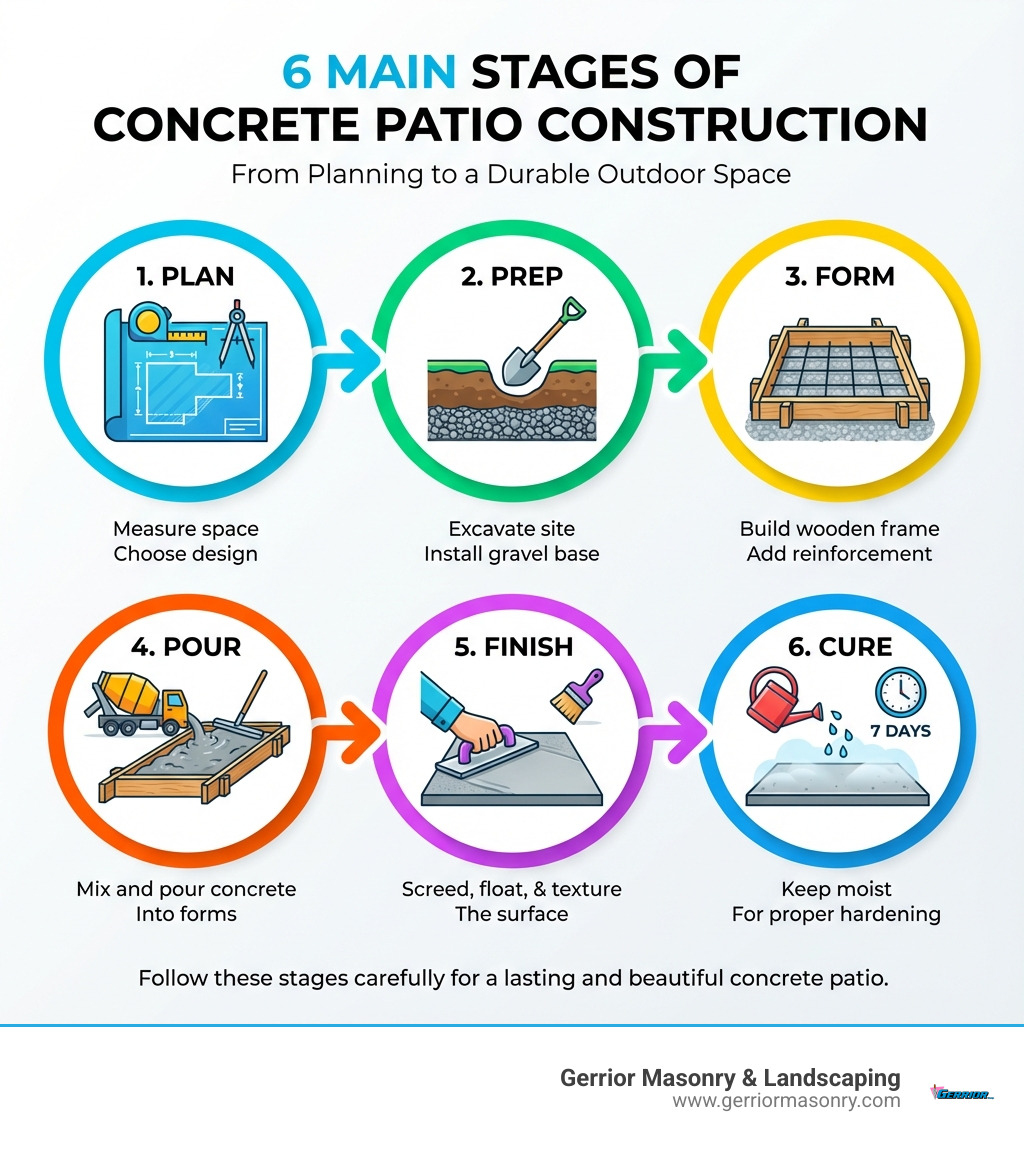

Concrete patio construction can be a rewarding project that transforms your backyard into a functional outdoor living space. A properly built patio involves careful planning, site preparation with a compacted gravel base, building forms, adding reinforcement like rebar, and then pouring, finishing, and curing the concrete. A well-executed project can last over 30 years with minimal maintenance.

Why choose concrete? It’s durable, cost-effective, and offers versatile design options, from basic gray slabs to stamped patterns that mimic stone or brick. While a DIY approach can save 40-50%, professional installation ensures optimal results, especially for complex designs.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years of experience in concrete patio construction across Massachusetts, I’ll guide you through the proven techniques to ensure your patio stands the test of time.

Planning and Preparing for Your Concrete Patio Construction

A beautiful outdoor living space begins with meticulous planning. For concrete patio construction, a solid foundation is paramount to achieving a lasting result.

Why Choose a Concrete Patio?

Concrete patios offer a compelling blend of practicality and value. Their primary benefit is unmatched durability; a professionally installed patio can last 30 years or more, easily withstanding the harsh freeze-thaw cycles of a Massachusetts winter and the heat of summer. This longevity translates to exceptionally low maintenance. Unlike pavers with joints where weeds can grow, a solid concrete slab is a fortress against unwanted vegetation and pests. Maintenance typically involves only occasional cleaning and resealing every 2-3 years to keep it looking new. Financially, concrete is often more cost-effective than natural stone or high-end pavers, providing a premium look without the premium price tag. Beyond the practical, modern concrete offers incredible design versatility. It’s no longer just a gray slab—it can be stamped, stained, or textured to perfectly mimic materials like slate, flagstone, or wood, complementing your home’s unique aesthetic. For more on material selection, see our guide on Choosing the Perfect Flooring Material for Your Outdoor Patio.

Understanding Costs and Design Options for Your Concrete Patio

The cost of your concrete patio construction depends on size, complexity, and finishes.

Cost Factors and Estimates:

Based on internet data, average costs can range from $12 to $20 per square foot for standard finishes. However, highly customized projects with premium stamped or colored finishes can exceed $60 per square foot.

Important Disclaimer: Please note that these cost figures are general estimates based on publicly available internet data and not actual costs for Gerrior Masonry & Landscape Construction services. Prices can vary significantly based on material costs, labor rates, site conditions, and specific design choices. For an accurate estimate for your project, we encourage you to contact us for a personalized consultation.

Decorative Finishes and Design Possibilities:

Today’s concrete offers limitless design options to create a truly custom look:

- Standard Finishes: A classic non-slip broom finish is safe and attractive, while a smooth troweled finish offers a sleek, modern look for covered areas.

- Stamped Concrete: This popular technique uses molds to press realistic textures like Ashlar slate, cobblestone, or wood grain into fresh concrete, offering the beauty of natural materials with superior durability.

- Stains and Colors: Color can be mixed in before pouring (integral color) for a deep, consistent hue, or applied topically after curing. Acid stains create rich, marbled tones, while water-based stains offer a wider, more opaque palette of colors.

- Exposed Aggregate: This finish reveals the natural stones within the mix by removing the top layer of cement paste, providing a beautiful, durable, and highly slip-resistant surface.

For more inspiration, see our Backyard Patio Designs.

Patio Placement Considerations:

Strategic placement is key to maximizing your patio’s usability. Think about sun exposure—do you want a sunny spot for morning coffee or a shaded area for relief from the hot afternoon sun? Consider prevailing winds and how you might use landscaping or structures to create a comfortable microclimate. Ensure easy access from your house, typically from a kitchen or living area. The transition from your home’s doorway to the patio should be seamless and safe, ideally no more than an 8-inch step down. Also, consider privacy from neighbors and proximity to utilities if you plan to include features like an outdoor kitchen, lighting, or a water feature.

Essential Site Prep for a Durable Concrete Patio Construction

Proper site preparation is the most critical phase for a long-lasting patio.

1. Excavation and Gravel Base:

First, mark the patio layout. Excavate the area to a depth of 8-9 inches to accommodate a 4-inch concrete slab and a 4-inch gravel base. In Massachusetts, we may excavate deeper to mitigate frost heave. After clearing the area, we add a 4-6 inch layer of crushed stone, such as CA6 or CA7, compacting it thoroughly.

2. Grading and Forms:

The compacted base must be graded with a slope of 1/8″ per foot away from your house to ensure proper water runoff. This is a key element of proper drainage in hardscaping. Next, build a sturdy formwork using 2×6 lumber, staked securely in place. The tops of the forms will define the final height and slope of your patio.

3. Reinforcement:

To add tensile strength and control cracking, reinforcement is essential. We use a grid of 1/2-inch rebar or welded wire mesh, ensuring it sits in the middle of the slab’s thickness. We also recommend using fibermesh mixed into the concrete for added durability against shrinkage cracks. The minimum patio thickness is 4 inches, but may be increased for heavy loads like an outdoor kitchen.

Building, Finishing, and Maintaining Your Masterpiece

With the site prepared, it’s time to pour and finish your concrete patio, changing raw materials into your envisioned outdoor space.

The Step-by-Step Pouring and Finishing Process

Pouring concrete is a time-sensitive process requiring coordination. For a DIY project, you’ll need helpers and tools like wheelbarrows, shovels, a screed board, and floats. For larger projects, ordering ready-mix concrete is more practical. We recommend a 4,500 psi air-entrained concrete mix with fibermesh. This high-strength mix is designed to withstand Massachusetts’ freeze-thaw cycles, while fibermesh helps prevent shrinkage cracks.

- Pour and Screed: Pour the concrete into the forms, spreading it evenly. Immediately use a long, straight 2×4 (a screed board) in a sawing motion across the top of the forms to level the surface and remove excess concrete, establishing the final grade.

- Float and Edge: After the initial water (bleed water) disappears from the surface, use a bull float to smooth the slab and push down aggregates. This brings the “cream” to the surface for a finer finish. As it stiffens, use an edger tool along the forms to create clean, rounded edges that are less prone to chipping.

- Joints and Texture: To manage the natural shrinkage that causes cracking, we cut control joints into the slab for any area larger than 10×10 feet. These joints are cut to a depth of one-quarter of the slab’s thickness, creating a weakened plane for cracks to follow predictably. Once the concrete is firm, create a safe, non-slip surface. The most common method is a broom finish, achieved by gently dragging a stiff broom across the slab.

- Cure the Concrete: Curing is a critical chemical hydration process, not a drying process. To achieve maximum strength, the concrete must be kept continuously moist for at least seven days. This can be done by misting it, covering it with plastic sheeting, or applying a liquid curing compound. After 48 hours, the forms can be carefully removed. For more details, you can review guides on how to build a concrete pad.

Ensuring Longevity: Maintenance and Common Problem Prevention

A well-built concrete patio can last over 30 years with proper care. The most important maintenance task is sealing. After the concrete has fully cured (at least 28 days), apply a high-quality sealer and reapply every 2-3 years to protect against moisture, stains, and UV damage. You can choose between film-forming sealers (like acrylics) for a protective topcoat or penetrating sealers for a more natural look. Regular cleaning is simple: sweep and hose down as needed, using a pH-neutral cleaner for tougher stains. A pressure washer on a low setting can also be used with caution.

While proper concrete patio construction—including a compacted base, reinforcement, and control joints—is the best defense against cracking, small hairline cracks may still appear. Fill these promptly with a flexible concrete crack sealant to prevent water intrusion and further damage. To prevent surface spalling or flaking, never use rock salt or other chloride-based de-icers on your patio, especially during its first winter. Use sand or a concrete-safe de-icer instead. For more seasonal tips, see our guide on Preparing for Spring: Your Guide to a Beautiful Hardscape.

DIY vs. Hiring a Pro: Making the Right Choice

Deciding between a DIY project and hiring a professional involves weighing cost against complexity.

DIY vs. Professional:

A DIY approach can save 40-50% on labor costs. However, it requires significant physical effort, the right tools, and knowledge of proper techniques. Mistakes in mixing, finishing, or curing can lead to a poor-quality result that’s costly to fix.

Hiring a professional ensures expertise, efficiency, and a high-quality finish. An experienced contractor understands local conditions like Massachusetts’ frost heave, uses the right materials and reinforcement, and can execute complex decorative designs flawlessly. Professionals also typically offer a warranty, providing peace of mind. A well-built patio, whether DIY or professionally installed, significantly increases your home’s resale value by adding attractive, functional living space.

Choosing a Contractor:

If you hire a pro, ask key questions:

- How do you prepare the site and ensure proper drainage?

- What reinforcement and concrete mix do you recommend?

- Can I see examples of your stamped or decorative work?

- Do you provide a detailed estimate and warranty?

For complex projects or to guarantee a masterpiece, hiring an expert Patio Installation Contractor is the best choice. We invite you to Contact us for your patio installation needs to discuss your project.

Gerrior Masonry & Landscape Construction is based in Woburn, MA, and proudly serves Middlesex and Essex County, Massachusetts, with expert hardscaping and masonry services.