chimney flashing replacement: 7 Powerful Ways to Stop Leaks 2025

Why Proper Chimney Flashing Matters for a Leak-Free Home

If you’re dealing with a leaky chimney, chimney flashing replacement is likely the solution you need. Here’s what you should know:

Chimney Flashing Replacement at a Glance:

* Average Cost: $400-$1,600 (based on internet data)

* DIY Cost: $20-$200 for materials

* Professional Labor: Approximately $75/hour

* Typical Lifespan: 15-30 years when properly installed

* Signs of Failure: Water stains on ceiling, rust streaks, discolored bricks

* Best Time for Replacement: During roof replacement or in dry, mild weather

Chimney flashing replacement involves installing new metal barriers where your chimney meets the roof to prevent water infiltration. This critical roofing component creates a waterproof seal that diverts rainwater away from the vulnerable junction where your chimney penetrates the roof. When flashing fails, it’s often the first place experienced roofers check when water intrusion occurs.

Like weather stripping for your doors and windows, flashing creates a protective barrier against the elements. However, unlike simple weather stripping, flashing failure can lead to extensive and expensive water damage to your home’s structure.

Most chimney leaks aren’t actually from the chimney itself but from deteriorated or improperly installed flashing. Sheet-metal flashings are the most common cause of chimney leaks, and while temporary fixes like roofing tar might seem to solve the problem, they only mask the underlying issue.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction, and I’ve overseen hundreds of chimney flashing replacement projects throughout my 34 years of experience serving Massachusetts homeowners. Our team specializes in ensuring your chimney isn’t just visually appealing but also functionally sound against New England’s challenging weather.

According to the National Roofing Contractors Association, proper flashing installation is critical to preventing water damage in homes, and should be inspected regularly as part of routine roof maintenance.

Chimney flashing replacement helpful reading:

– chimney chase cover replacement cost

– chimney chase cover replacement near me

Why Chimney Flashing Fails and How to Spot Trouble

There’s an old saying among Massachusetts homeowners: “April showers bring May flowers—and chimney leaks.” As the spring rains arrive, our phone at Gerrior Masonry starts ringing with calls about water finding its way inside homes through chimney areas.

Your chimney stands as one of the most vulnerable points on your entire roof. The place where the chimney meets your roof creates a natural interruption in your home’s water-shedding system. When chimney flashing replacement becomes necessary, it’s usually because of one of these common failures:

Age and weathering take their toll on even the highest quality flashing. After years of expanding in summer heat and contracting in winter cold, metal flashings fatigue and crack. The sun’s UV rays break down caulking compounds, while wind-driven rain tests every seam.

Improper installation is surprisingly common, especially when the original roofer rushed or cut corners. “I’ve seen flashing that wasn’t even properly stepped into the shingles,” notes our lead mason. “It looked fine from the ground but provided zero protection.”

Rust and corrosion eat away at galvanized steel flashing over time, particularly in coastal areas where salt air accelerates deterioration. Those tiny rust spots eventually become actual holes.

House settling creates subtle movements that can break flashing seals. As your foundation shifts slightly over decades, that rigid chimney doesn’t move with it, stressing the connection point.

Ice dam formation in New England winters can be particularly damaging. When ice builds up along your roof edge, the expanding ice can literally lift or tear flashing away from the chimney.

What makes chimney leaks particularly tricky is how they manifest. Water entering around your chimney rarely drips straight down. Instead, it typically travels along rafters or roof decking before appearing as ceiling stains—often several feet away from the actual chimney. I’ve seen homeowners focus on plumbing leaks or roof vents when the real culprit was failing chimney flashing all along.

“Once flashing fails, it should be fully replaced to avoid recurring leaks,” explains our lead mason. “Cement and caulk are temporary fixes at best.”

Early-Warning Signs You Can’t Ignore

Don’t wait until your ceiling resembles a Rorschach test of water stains. Here are the early warning signs that your chimney flashing replacement time has arrived:

Puddles in the firebox often surprise homeowners who assume water in the fireplace must be coming down the flue. In reality, water collecting in your firebox typically indicates flashing failure, not a chimney cap problem.

Discolored bricks around your chimney tell a story. Dark water stains or white chalky deposits (called efflorescence) mean moisture is penetrating the masonry—often through failed flashing.

Rust streaks running down from flashing points are like neon signs announcing corrosion. These orange-brown trails indicate your metal flashing is actively deteriorating.

Mortar gaps where counter flashing meets the chimney brick provide easy entry points for water. When this mortar cracks or falls out, your water barrier is compromised.

One client in Wilmington called us after noticing a musty smell in their living room. Our inspection revealed water had been seeping through deteriorated flashing for months, creating hidden mold inside the wall adjacent to the chimney. What could have been a simple chimney flashing replacement had escalated to a much costlier repair.

How Often Should You Inspect?

The best defense against expensive water damage is regular inspection. Here’s the schedule we recommend to our Massachusetts clients:

Yearly professional inspection should be part of your home maintenance calendar. The National Fire Protection Association recommends annual chimney inspections not just for fire safety but also to identify water issues before they cause structural damage. Late autumn is ideal timing, before winter weather puts your flashing to the test.

Seasonal self-checks with binoculars from ground level can catch obvious problems. Look for missing or lifted flashing, excessive rust, or damaged caulking. The changing of seasons—particularly after winter—is the perfect time for these visual inspections.

Post-storm walk-arounds are worth your time after severe weather. High winds, hail, or heavy rain can damage or dislodge flashing. A quick check might catch problems before the next rainfall turns them into leaks.

Spring leak vigilance pays off because this is when most chimney leaks reveal themselves. As snow melts and spring rains arrive, water infiltration becomes more obvious. Don’t ignore even minor signs of moisture.

Most quality flashing installations last 15-30 years, but this lifespan varies dramatically based on your local climate, the materials used, and installation quality. If your flashing is approaching the 15-year mark, a professional evaluation makes sense even without visible problems.

Preventative maintenance always costs less than emergency repairs and water damage restoration. A timely chimney flashing replacement could save you thousands in potential damage to your home’s structure, insulation, and interior finishes.

Gerrior Masonry & Landscape Construction is based in Woburn, MA, and services Middlesex and Essex County, Massachusetts.

Anatomy & Material Choices for a Leak-Proof System

Understanding the components of chimney flashing helps you make informed decisions about replacement options. A proper chimney flashing system isn’t just a single piece of metal—it’s like a well-choreographed dance of components working together to channel water away from where your chimney meets your roof.

Understanding the Three-Piece System

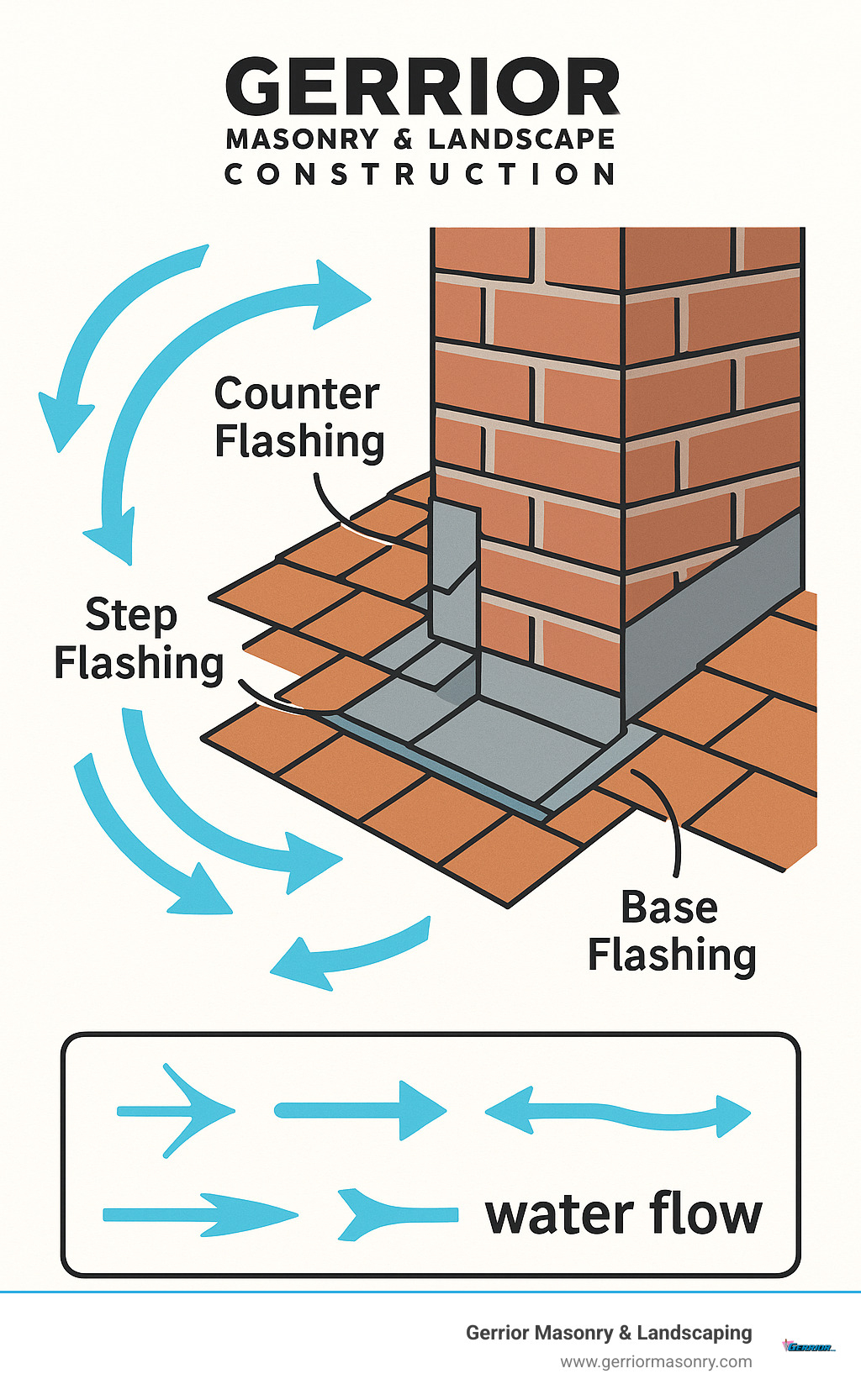

When we talk about chimney flashing replacement, we’re actually discussing a system of three main components working together. Think of it as a three-layer defense against water intrusion.

The first layer is your base flashing, also called apron flashing. This is essentially the foundation of your flashing system—a wide piece at the bottom that extends from under your shingles and runs 4-6 inches up the front of your chimney. It’s your first line of defense, directing water onto the roof surface rather than behind the chimney.

Next comes the step flashing, those L-shaped pieces running up both sides of your chimney. Each piece overlaps the one below it and weaves between your shingle courses—creating a series of “steps” that channel water away from the chimney. I often tell homeowners to picture it like shingles for your chimney’s sides.

The final protective layer is your counter flashing or cap flashing. This is embedded directly into the mortar joints of your chimney and overlaps both the base and step flashing below. It’s like the roof over your flashing system, preventing water from sneaking in from above.

“Flashing components work like a zipper’s teeth,” explains our senior mason. “Each piece must properly overlap and interlock with adjacent pieces to create a waterproof barrier. If even one piece is compromised, the entire system can fail.”

For wider chimneys (over 30 inches), we also install what’s called a chimney saddle or cricket. This isn’t technically flashing, but rather a small peaked structure installed behind the chimney that diverts water around it instead of allowing it to pool. As one client memorably described it, “It’s like a tiny roof for your chimney’s back.”

Material Pros, Cons & Service Life

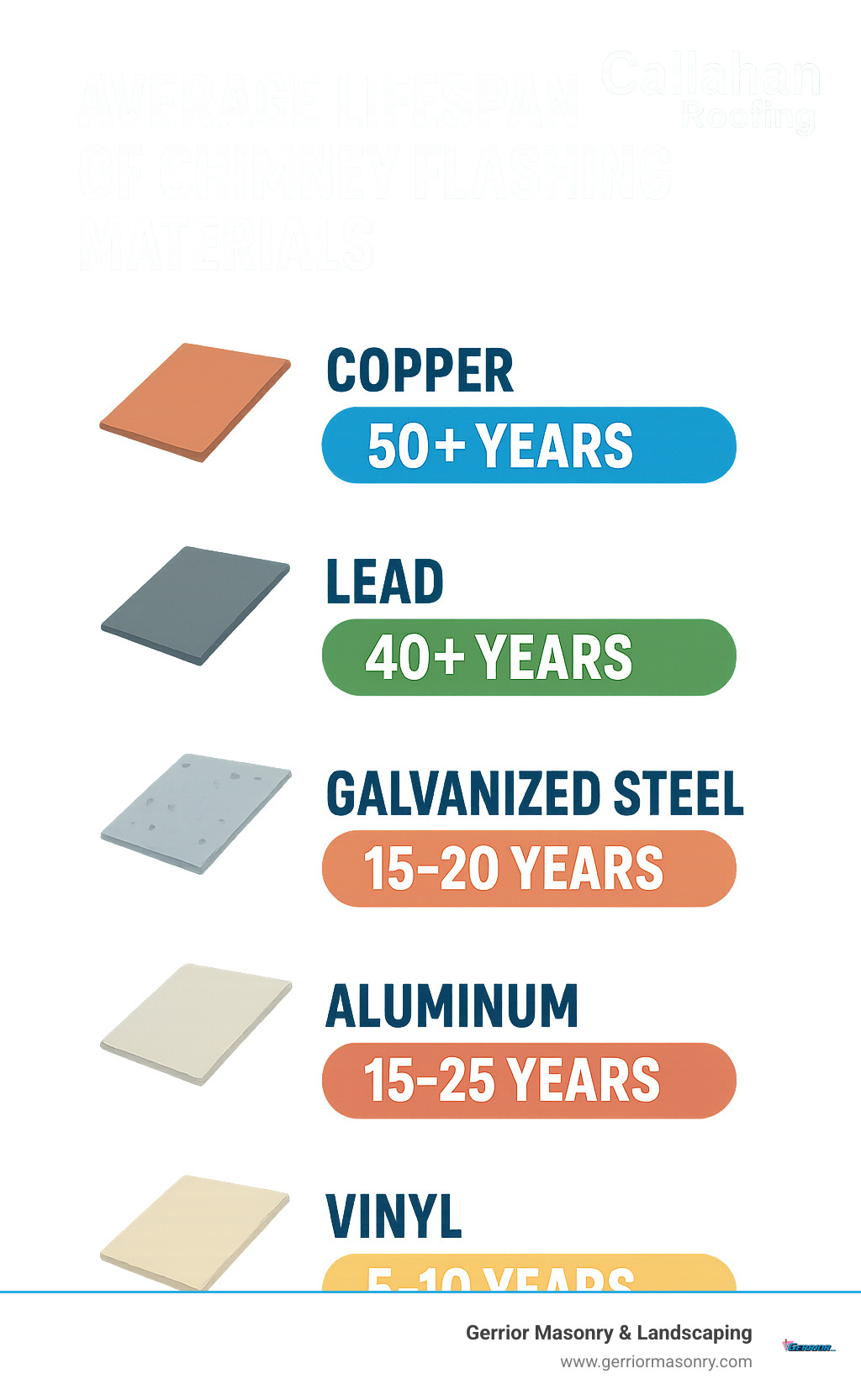

The material you choose for your chimney flashing replacement makes a huge difference in how long it will last and how much you’ll spend. Here’s what you need to know about the most common options:

Galvanized steel is the budget-friendly workhorse, costing around $0.50 per linear foot with a lifespan of 15-20 years. It’s readily available and gets the job done, but it will eventually rust and requires periodic painting to extend its life. For most Massachusetts homes on a budget, we recommend 26-gauge galvanized steel with proper painting.

Aluminum runs about $0.75 per linear foot and lasts 15-25 years. It’s lightweight and won’t rust, making it particularly good for coastal Massachusetts homes where salt air is a concern. The downside? It dents more easily than steel and has a somewhat shorter overall lifespan.

Copper is the premium choice at $2-$3 per linear foot, but its 50+ year lifespan makes it worth considering. “Copper flashing is like buying a forever home—you’ll likely move before it needs replacement,” notes our project manager. It develops a beautiful patina over time and is particularly appropriate for historic New England homes. We typically use 16-oz copper for premium installations.

Lead costs $1.50-$2 per linear foot and lasts 40+ years. It’s incredibly malleable, making it excellent for complex chimney shapes, but environmental concerns have made it less common in modern installations.

Vinyl/PVC is the cheapest option at about $0.30-$0.40 per linear foot, but its 5-10 year lifespan makes it truly a temporary solution. It’s prone to cracking in our harsh New England winters and is generally not recommended for permanent installations.

One critical consideration that many homeowners overlook is material compatibility. Mixing different metals can cause galvanic corrosion, where one metal essentially attacks the other. For example, rainwater running from copper flashing onto galvanized steel can accelerate corrosion. Always use matching metals throughout your entire flashing system—this isn’t a place to mix and match!

When choosing materials, consider both your budget and how long you plan to stay in your home. The higher upfront cost of copper often pays for itself in longevity and reduced maintenance, while galvanized steel offers a solid middle-ground option for most Massachusetts homes.

Chimney Flashing Replacement: Cost, Timing & Code Essentials

When it comes to chimney flashing replacement, understanding the costs involved helps you plan your home maintenance budget effectively. Based on internet data (not Gerrior Masonry’s specific pricing), most homeowners spend between $400 and $1,600 for a standard replacement, though more complex jobs can reach upwards of $4,800 for larger or more intricate chimneys.

“The price range for chimney flashing replacement reminds me of buying a suit,” says Joe Gerrior. “You can get something off the rack or custom-custom, depending on your needs and budget.”

Several key factors influence what you’ll pay:

Your chimney’s size matters significantly – a standard chimney might run $750-$1,000, while larger ones requiring cricket installation can cost two to three times more. The steepness of your roof also impacts the bottom line, with particularly pitched roofs adding 20-30% to labor costs due to additional safety requirements.

Accessibility plays a major role too. That charming third-floor chimney might look beautiful, but reaching it safely requires more equipment and time. Material choices further affect your investment – copper flashing might cost substantially more upfront than galvanized steel but could outlast it by decades.

Professional installation typically runs about $75 per hour, with labor representing 60-70% of your total cost. If you’re considering the DIY route, materials alone might cost just $20-$200, but the expertise gap can lead to costly water damage down the road.

Budget Break-Down & Money-Savvy Moves

Smart homeowners find ways to maximize value while ensuring quality work. One of our Chelmsford clients saved nearly 25% by scheduling her chimney flashing replacement during her annual chimney maintenance visit.

Bundle services whenever possible. Combining flashing work with chimney cleaning or minor roof repairs often results in package pricing that benefits everyone. Your contractor saves on travel time and setup, passing those savings to you.

Consider off-season timing. Massachusetts contractors often have more flexible schedules during late fall or early spring. As one client joked, “Nobody wants to be on a roof in November except people who really know what they’re doing!”

Choose materials strategically. While copper offers best longevity (and a beautiful patina over time), properly installed aluminum or galvanized steel provides excellent protection at a lower price point. For historic homes, the investment in copper often makes sense; for newer construction, other options might be more cost-effective.

Address small problems before they become big ones. That minor rust spot or lifted flashing corner won’t fix itself, and early intervention prevents the extensive water damage that drives up repair costs dramatically.

Check your insurance coverage. Some homeowners’ policies cover flashing replacement, particularly if damage resulted from a specific event like a severe storm. It never hurts to ask!

When Is Full Replacement Unavoidable?

Sometimes repairs simply won’t cut it. When rust has eaten through your flashing in multiple spots, you’re facing a full replacement situation. Multiple leak points generally indicate system-wide failure rather than isolated problems.

Roof replacement time is flashing replacement time. One of the most shortsighted mistakes homeowners make is reusing old flashing when installing a new roof. This undermines your entire roof investment and virtually guarantees problems down the road.

After chimney rebuilding or significant repairs, new flashing installation is non-negotiable. The interface between your newly repaired chimney and existing roof needs proper protection from day one.

For sided chimneys, improper clearance between siding and roofline often requires correction through comprehensive flashing replacement. This is particularly important in New England, where freeze-thaw cycles can wreak havoc on improperly flashed joints.

It’s also worth noting that The International Building Code requires chimney crickets on units over 30 inches wide. According to the International Code Council, this requirement helps prevent water pooling behind chimneys, which can lead to significant damage over time. If your wide chimney lacks this important water-diverting feature, replacement provides the perfect opportunity to bring your home up to code while solving water issues.

Many homeowners find additional information about related services helpful when planning their chimney flashing replacement. You might want to explore Chimney Repair Cost or consider Chimney Repointing Near Me as complementary services to ensure your entire chimney system functions properly.

Step-by-Step Chimney Flashing Replacement Guide

Whether you’re considering DIY or want to understand what professionals will do, here’s a comprehensive guide to the chimney flashing replacement process.

DIY Chimney Flashing Replacement Checklist

Note: This is an advanced DIY project requiring roofing experience, proper safety equipment, and comfort working at heights. When in doubt, consult professionals.

Tools and Materials Needed:

– Safety harness and roof brackets

– Extension ladder with stabilizers

– Heavy-duty gloves and non-slip boots

– Pry bar and hammer

– Utility knife and tin snips

– Roofing nails and hammer

– Self-adhering ice-and-water shield

– Sheet metal for flashing (galvanized steel, aluminum, or copper)

– Polyurethane caulk and caulk gun

– Masonry drill and anchors (for counter flashing)

– Angle grinder with masonry blade (for reglet cutting)

Step 1: Preparation and Safety

– Set up fall protection equipment including roof brackets and planks

– Secure ladder with a helper at the base

– Work early in the morning to avoid heat-softened shingles

– Take detailed measurements of your chimney and roof slope

Step 2: Remove Old Flashing

– Remove shingles within 18-24 inches of the chimney

– Carefully pry out old flashing pieces, working from top down

– Clean all surfaces of old caulk, tar, and debris

– Inspect roof decking for water damage and repair if necessary

Step 3: Apply Waterproof Membrane

– Install self-adhering ice-and-water shield around the chimney base

– Extend membrane at least 12 inches past each side of the chimney

– Run it 4-6 inches up the chimney sides

– This critical step provides backup protection under the flashing

Step 4: Install Base Flashing

– Cut and bend base flashing to fit the front of the chimney

– Extend it at least 4 inches up the chimney face and 3 inches onto the roof

– Secure with roofing nails along the roof edge only (not on the vertical surface)

– Begin shingling up to this point

Step 5: Install Step Flashing

– Cut L-shaped step flashing pieces (typically 8×8 inches)

– Install the first piece at the chimney corner, overlapping the base flashing

– Place a shingle over this flashing, then the next step flashing piece

– Continue alternating shingles and step flashing up the chimney sides

– Each piece should overlap the previous one by at least 2 inches

Step 6: Install the Chimney Saddle/Cricket (if needed)

– For chimneys wider than 30 inches, install a pre-fabricated or custom-built cricket

– This diverts water around the back of the chimney

– Flash the cricket with the same material as the chimney flashing

Step 7: Install Counter Flashing

– Cut a reglet (groove) in the mortar joints about 1 inch deep

– Cut counter flashing pieces to fit, with the upper edge bent at 90 degrees to insert into the reglet

– Insert flashing into the groove and secure with masonry anchors

– Bend the lower portion down to cover the step flashing by at least 2 inches

– Seal the reglet with matching mortar or polyurethane caulk

Step 8: Finish and Test

– Apply polyurethane caulk at all joints and overlaps

– Complete shingling around the chimney

– Test the installation by running water around the chimney for at least 5 minutes

– Check the attic and interior for any signs of leaks

One DIY enthusiast from Woburn shared: “Having the sheet metal shop pre-cut my flashing pieces saved hours of frustration. I just provided the measurements and picked up custom-bent pieces three days later.”

Professional Chimney Flashing Replacement Timeline

When hiring professionals like our team at Gerrior Masonry, here’s what to expect:

Day 1: Preparation and Assessment (1-2 hours)

– Detailed inspection of existing flashing, chimney, and surrounding roof

– Measurements for custom flashing fabrication

– Site preparation including safety equipment setup

Day 2: Installation (4-6 hours)

– Removal of old flashing and inspection of decking

– Application of ice-and-water shield

– Installation of base, step, and counter flashing

– Cricket installation if required

– Quality checks and cleanup

Post-Installation: Documentation and Warranty

– Final inspection and documentation per NRCA recommendations

– Provision of warranty information

– Guidance on maintenance and future inspections

Our team documents every step of the process with photos, creating a comprehensive record of the installation that can be valuable for warranty purposes or future reference.

Safety First on the Roof

Whether DIY or watching professionals work, safety should always be the priority in chimney flashing replacement:

- Fall protection: Always use a personal fall arrest system when working on roofs

- Ladder safety: Secure ladders at a proper angle (1:4 ratio) with stabilizers

- Footwear: Wear soft-soled, non-slip boots for roof traction

- Weather conditions: Never work on wet roofs or during windy conditions

- Power tool safety: Use eye and ear protection when cutting reglets or metal

- Buddy system: Have a helper on the ground for emergency assistance

“No chimney repair is worth risking your safety,” emphasizes our safety coordinator. “Professional roofers and masons have the training and equipment to work safely at heights that can be dangerous for homeowners.”

Pro Tips, Common Mistakes & Maintenance Hacks

After three decades of chimney flashing replacement work throughout Massachusetts, we’ve seen every mistake possible. Here are the most common pitfalls to avoid and professional insights to ensure your flashing lasts:

Common Mistakes

That black goop you see in the photo above? That’s what we call a “temporary fix that becomes permanent until it fails.” Over-reliance on roofing tar is probably the most common mistake we encounter in our work.

“Sealant should be a redundancy, not the primary waterproofing method,” explains our lead mason. Many budget contractors slather on roofing cement to compensate for poor flashing installation, but within a year or two, that tar cracks and water finds its way in. Proper mechanical overlaps should direct water away even if all the sealant disappeared overnight.

Another frequent blunder we see is mixing metals – like installing copper step flashing with aluminum counter flashing. This creates a chemical reaction called galvanic corrosion that can eat through your flashing in half the expected time. As one homeowner in Reading finded, “My bargain contractor’s mixed-metal installation cost me $3,000 in water damage repairs just 18 months later.”

Skipping the ice-and-water shield underneath your flashing is like forgetting to wear a belt with suspenders – you’re missing a critical backup system. This self-adhering membrane creates a second line of defense when water inevitably finds its way behind the flashing. The National Roofing Contractors Association specifically recommends it for all roof penetrations.

On sided chimneys, we frequently see siding installed flush against the roofline. This is a recipe for disaster. Water needs at least a ¼-inch gap (preferably 1 inch) to drain properly. As one client colorfully put it, “Water needs somewhere to go besides into your walls.”

Forgetting the cricket behind wide chimneys is another common oversight. If your chimney is wider than 30 inches, you need this small peaked structure to prevent water pooling. This isn’t just a good idea—it’s required by the International Building Code for new construction. One Lexington homeowner told us, “I never knew what a cricket was until water damage forced me to learn – the expensive way.”

Pro Maintenance Tips

“An ounce of prevention is worth a pound of cure” might be a cliché, but it’s absolutely true when it comes to chimney flashing replacement. Smart homeowners combine chimney flashing checks with their annual chimney sweep for efficiency and savings. Our customers who bundle these services typically save 15-20% compared to scheduling them separately.

Those gutters you’ve been meaning to clean? They’re more connected to your chimney flashing than you might think. Clogged gutters cause water to back up and find the path of least resistance – often behind your flashing. A twice-yearly gutter cleaning can prevent this common problem.

For galvanized steel flashing, a little paint goes a long way. To extend its lifespan, it should be cleaned and repainted every 3-5 years. “Think of it as sunscreen for your flashing,” our team often explains. “It prevents the harmful UV rays from breaking down the galvanization.”

Documentation might sound boring, but it’s incredibly valuable. Keep records of installation dates, materials used, and any repairs for warranty purposes. One Arlington homeowner shared this brilliant tip: “I take photos of my chimney flashing every spring and compare them to previous years’ photos. It’s amazing how this simple habit helps me spot gradual changes before they become problems.”

When winter arrives, be cautious with snow removal. When clearing snow from the roof, stay at least 12 inches away from the chimney to avoid damaging flashing with your shovel or rake. We’ve repaired countless flashing systems damaged by overzealous snow removal.

Perhaps the most important maintenance tip is also the simplest: address small issues immediately. A $10 tube of quality polyurethane caulk can prevent thousands in water damage if applied at the first sign of separation. It’s like dental work – a small filling now prevents a root canal later.

For homeowners looking to learn more about maintaining their chimneys, our Chimney Repointing Near Me guide provides additional insights into keeping your entire chimney system in top condition. Flashing is just one component of your chimney’s defense against the elements – regular maintenance of the mortar, crown, and cap are equally important for preventing costly water damage.

Frequently Asked Questions about Chimney Flashing Replacement

How long does properly installed flashing last?

The lifespan of your chimney flashing largely depends on what it’s made of and your local weather conditions. Copper flashing is the marathon runner of the bunch, often lasting 50+ years with proper care. Galvanized steel typically needs replacement after 15-20 years, while aluminum generally falls somewhere in between at 15-25 years.

If you live in coastal Massachusetts towns like Marblehead or Swampscott, be aware that salt air can be pretty tough on your flashing, potentially shortening its life by 20-30%. It’s like how beach houses need more frequent painting—salt air just accelerates wear on metals.

“My copper flashing is 40 years old and still performing perfectly because the previous owner was religious about maintenance,” one Lexington homeowner told us recently. This highlights an important point: regular check-ups and quick fixes to small issues can add years to your flashing system. Think of it like dental care—regular cleanings prevent bigger problems down the road.

Is chimney flashing replacement a DIY project or professional job?

While technically you could tackle chimney flashing replacement yourself if you have roofing experience, there are several compelling reasons to call in the pros:

Safety concerns top the list—working on roofs (especially steep ones) carries significant fall risks. Professional crews come equipped with proper harnesses, roof brackets, and the training to use them correctly.

Specialized tools make a big difference too. Proper installation requires equipment like metal brakes for bending flashing, reglet cutters for creating grooves in mortar, and other specialized tools most homeowners don’t have sitting in their garage.

The technical expertise involved shouldn’t be underestimated either. Creating proper overlaps, bends, and securing techniques requires experience to ensure everything stays watertight during New England’s notorious weather changes.

A Woburn homeowner put it perfectly: “I’m pretty handy, but after researching what’s involved in flashing replacement, I realized the $800 I spent hiring professionals was worth every penny for the peace of mind alone.”

If you’re still determined to DIY, here’s a smart compromise: have a sheet metal shop fabricate the custom pieces based on your measurements. This simplifies the most technical aspect of the job while still saving some money.

Can flashing be repaired or does it always need full replacement?

Sometimes you can get away with repairs rather than a complete overhaul. Minor issues that might qualify for repair include:

Small holes or punctures in otherwise sound flashing can be patched with compatible material and sealed with high-quality caulk. Loose counter flashing that’s still in good condition can be reattached and resealed. And if the only issue is deteriorated caulk, simply removing and replacing it with fresh polyurethane sealant might do the trick.

However, our senior mason often tells clients, “Repairing flashing is like putting a Band-Aid on a deep cut that needs stitches. It might stop the bleeding temporarily, but it’s not addressing the underlying problem.”

Complete replacement becomes necessary when your flashing shows extensive rust or corrosion, has multiple failure points, or if you’re experiencing recurring leaks despite repairs. And it’s always best to replace flashing when installing a new roof, even if it looks okay—the savings from reusing old flashing are minimal compared to potential water damage costs.

One Burlington client learned this lesson the expensive way: “We tried three different repairs over two years before finally replacing the entire flashing system. We could have saved money by doing it right the first time.”

Gerrior Masonry & Landscape Construction is based in Woburn, MA, and services Middlesex and Essex County, Massachusetts. Our experienced team can help determine whether your chimney flashing needs repair or replacement.

Conclusion

When it comes to protecting your home from water damage, chimney flashing replacement isn’t just another maintenance task—it’s an essential investment in your home’s long-term health and your family’s comfort.

Think of your chimney flashing as the first line of defense where your roof meets your chimney. Like a good raincoat with properly sealed seams, it keeps water flowing away from this vulnerable junction rather than seeping into your home’s structure.

Throughout my years serving Massachusetts homeowners, I’ve seen how proper flashing installation prevents thousands in potential damage. One Tewksbury client told me, “After replacing our flashing, we finally had our first rainstorm without checking the ceiling for new water stains. That peace of mind is priceless.”

Whether you decide to hire professionals (which I recommend for most homeowners) or tackle this as an advanced DIY project, understanding what goes into a quality installation helps ensure you’ll get results that stand up to our challenging New England weather.

As you consider your options, remember these essential points:

Make annual chimney inspections part of your home maintenance routine, particularly before winter sets in. Those few minutes with binoculars from the ground could save you thousands in potential repairs.

Don’t ignore small problems—that minor rust spot or tiny gap in your caulking won’t fix itself, and water is remarkably persistent in finding its way into your home.

Choose quality materials that match your budget and climate needs. While copper offers the longest service life, properly installed aluminum or galvanized steel can provide excellent protection when maintained regularly.

Proper installation with correct overlaps and mechanical fastening is far more important than relying on sealants alone. As we say in the trade, “Caulk is your backup, not your primary defense.”

At Gerrior Masonry & Landscape Construction, we’ve been protecting Massachusetts homes with expert chimney flashing replacement for over three decades. Our attention to detail ensures your chimney won’t just look good—it will provide reliable protection against whatever weather comes your way.

For more information about our comprehensive chimney services, visit our chimney repairs page or reach out for a personalized consultation. We’re based in Woburn, MA, and proudly serve communities throughout Middlesex and Essex County, Massachusetts.