Chimney liner repair: Expert Safety 2025

Your Guide to Chimney Liners and Home Safety

Chimney liner repair is essential to prevent house fires and carbon monoxide leaks. A faulty liner is the #1 cause of chimney fires, and tests show a fire in an unlined chimney can ignite a home’s structure in just 3.5 hours.

A liner is the protective barrier inside your chimney that contains heat and gases. Over time, clay tiles crack, metal corrodes, and many pre-1940s homes have no liner at all. Annual professional inspections help catch issues early and avoid expensive or dangerous failures.

Repair options depend on damage. Minor issues may be addressed with a sealant system like HeatShield, while major deterioration typically calls for stainless steel relining. As Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp., I’ve overseen chimney liner repair projects across Massachusetts for over three decades, with owner oversight and experienced masons on every job.

What is a Chimney Liner and Why is it Important?

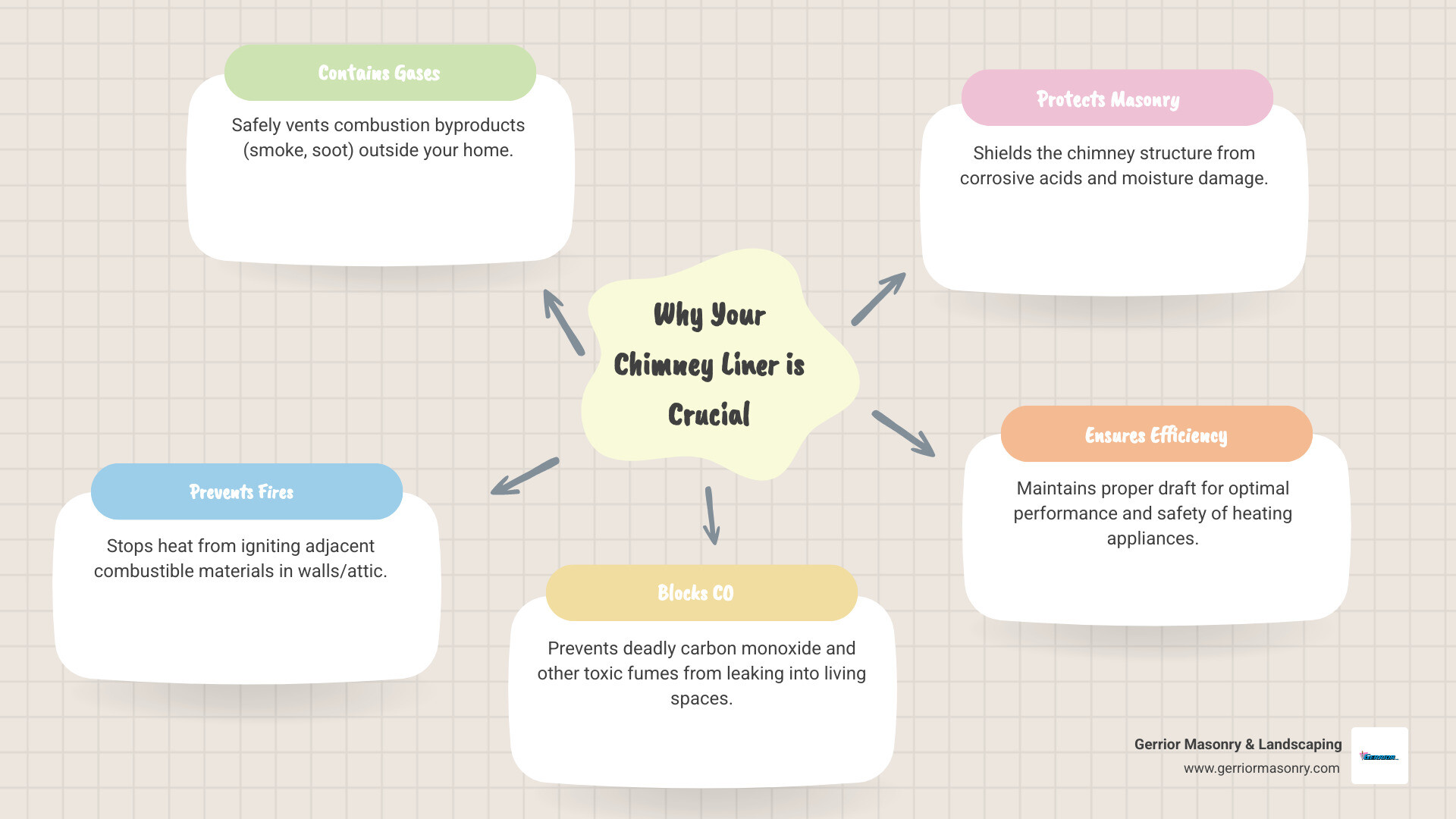

A chimney liner, also known as a flue liner, is a critical component that functions as the “exhaust pipe” for your fireplace or heating appliance. Its primary job is to channel the dangerous byproducts of combustion—including smoke, creosote, and deadly carbon monoxide gas—safely from your home to the outside. A properly functioning liner performs several essential safety functions:

- Contains Combustion Products: An intact liner prevents toxic gases like carbon monoxide from leaking into your living spaces. It also contains creosote, a highly flammable substance, preventing it from reaching combustible parts of your home’s structure.

- Protects Masonry from Corrosion: The hot, acidic gases produced by burning fuel attack the mortar joints and brickwork of your chimney. A liner shields the masonry from this corrosive attack, preventing structural deterioration from the inside out.

- Minimizes Heat Transfer to Combustibles: Chimneys pass close to wooden framing and insulation. A liner is a crucial barrier that insulates these materials from the intense heat of flue gases. Without it, a process called pyrolysis can lower the ignition temperature of nearby wood, creating a serious fire risk even without direct flame contact.

- Creates Proper Draft for Efficiency: For your appliance to work correctly, it needs a properly sized flue to create an adequate draft. An old, unlined, or improperly sized flue leads to poor performance, smoke spillage, and increased creosote buildup.

For more information on the various masonry services we offer, please visit our masonry services page.

Common Types of Chimney Liners and Their Lifespans

Chimney liners are made from different materials, each with its own lifespan and characteristics.

| Liner Type | Material | Typical Lifespan | Key Characteristics |

|---|---|---|---|

| Clay Tile | Terracotta clay | 15-50 years | Inexpensive and common, but susceptible to cracking from thermal shock and moisture. Not always suitable for modern appliances. |

| Stainless Steel | Flexible or rigid stainless steel | Up to 25 years | Durable, corrosion-resistant, and good for all fuel types. Often insulated for improved efficiency and suitable for most chimney shapes. |

| Cast-in-Place | Cement-like refractory material | Up to 50 years | Creates a seamless, insulated flue that reinforces the chimney structure. Ideal for deteriorating masonry but is the most expensive option. |

Clay tile liners have been the standard for decades due to their low cost, but they are prone to cracking from the thermal shock of a chimney fire or even rapid temperature changes from normal use. They are also susceptible to damage from moisture and acidic flue gases. Stainless steel liners are a popular and versatile modern solution. They can be rigid or flexible, making them suitable for chimneys with offsets or bends.

When installed with insulation, they significantly improve appliance performance and safety. They are durable and resistant to corrosion, making them compatible with all fuel types. Cast-in-place liners are a premium option that involves pumping a cement-like refractory mix around a former inside the chimney. This creates a seamless, smooth, and highly insulated flue that also reinforces the existing chimney structure, making it an excellent choice for older, deteriorating masonry.

What Causes Liner Damage?

Several factors can cause a chimney liner to fail, requiring chimney liner repair or replacement.

- Chimney fires that crack or shatter tiles

- Creosote buildup and acidic byproducts

- Moisture intrusion and freeze-thaw cycles

- Structural settling and misalignment

- Animal nesting and blockages

- Improper or mismatched installation

Understanding and Addressing Chimney Liner Repair

Signs, Risks, and Solutions for Your Flue

Signs That Your Chimney Liner Needs Repair or Replacement

Your chimney leaves clues when the liner is in trouble. Catching them early improves safety and can save money.

Look for:

- Clay or mortar fragments in your firebox

- Smoke entering rooms or weak draft

- Persistent smoky or chemical odors

- Exterior chimney stains or discoloration

- Cracks visible during inspection

- Decreased heating efficiency

- Rapid creosote accumulation

- Any history of a chimney fire

Age matters too. Clay liners often show issues within 5–15 years of regular use, stainless up to ~25 years, and cast-in-place up to ~50 years—actual life varies by use, fuel, and maintenance. If any of these signs sound familiar, schedule a professional inspection.

Can a Damaged Liner Be Repaired or Does It Need Replacement?

The appropriate solution—repair or full replacement—depends entirely on the type and extent of the damage, as well as the appliance being used. We tailor the solution to your specific situation after a thorough video inspection.

For clay tile flues with mortar joint damage or minor cracking, the HeatShield® system is often a cost-effective and reliable repair. This is a specially formulated ceramic-refractory sealant. If only the mortar joints have failed, the Joint Repair method uses a foam applicator to apply the sealant directly to the gaps. For more widespread surface damage like spalling or hairline cracks, the Resurfacing System is used. After a thorough cleaning, a “tie coat” adhesive is applied, followed by a thick layer of the HeatShield® material, creating a smooth, seamless, and gas-tight flue. This system is rated for temperatures over 2900°F, is suitable for all fuel types, and comes with a 20-year material warranty.

Full replacement becomes necessary when the liner has suffered catastrophic damage, such as collapsed tiles, extensive and deep cracking, or severe structural instability. It is also the required solution when you are upgrading your heating appliance, especially to a modern high-efficiency gas or wood stove. These units have different venting requirements and produce cooler, more corrosive flue gases that can quickly destroy an older clay liner.

For most replacements, stainless steel liners are our preferred choice. They are extremely durable, resist corrosion, and are approved for use with wood, oil, and gas appliances. They come in flexible or rigid forms to accommodate any chimney shape. Crucially, we almost always install them with a lightweight ceramic fiber insulation blanket (“cerwool”). This insulation keeps flue gas temperatures high, which improves draft, reduces creosote buildup, and adds an extra layer of safety by further isolating combustibles from heat. Many high-quality stainless steel liners come with lifetime material warranties, offering long-term peace of mind.

For more information about our comprehensive chimney services, visit our chimney repairs page.

The Risks and Costs of a Faulty Chimney Liner Repair

Ignoring liner problems or choosing substandard repairs invites serious hazards:

- Fire risk: even small gaps can let super-heated gases ignite nearby framing; unlined chimneys can trigger a house fire in about 3.5 hours.

- Carbon monoxide: a damaged liner can leak CO into living spaces.

- Poor performance: weak draft, smoke spillage, and higher fuel use.

- Structural damage: acids and moisture erode masonry from the inside out.

For technical background, see InspectApedia’s research.

Costs vary by liner type, height, access, and scope. Based on internet research (not Gerrior pricing):

- Minor repairs (e.g., HeatShield® joint repair/resurfacing, protective coatings): roughly $500–$2,000.

- Full relining (stainless steel, insulated, with necessary connections): about $2,500–$7,000+; complex jobs can exceed $10,000.

These are average costs from internet data only—not quotes. Gerrior Masonry provides detailed, written estimates after inspection.

The Role of Professional Inspections and Maintenance

Proactive maintenance and annual professional inspections are the best way to ensure your chimney system’s longevity and safety. The Chimney Safety Institute of America (CSIA) defines three levels of inspection:

- Level 1 Inspection: A standard visual check recommended annually for chimneys under continued service, examining readily accessible portions.

- Level 2 Inspection: Required for property sales, after system changes (like a new appliance), or after an event like a chimney fire. It includes a Level 1 inspection plus a video scan of the entire flue interior to identify hidden damage.

- Level 3 Inspection: Reserved for when a serious hazard is suspected that requires accessing concealed areas, which may involve minor demolition.

In addition to professional inspections, you can extend your liner’s life with proper use:

- Burn the Right Fuel: Only burn seasoned (dried) hardwood. Wet wood smolders and creates excessive, corrosive creosote. Never burn trash or treated wood.

- Schedule Regular Sweeping: The National Fire Protection Association (NFPA) recommends annual cleaning and inspection to remove flammable creosote.

- Install a Quality Chimney Cap: A cap is essential for keeping out damaging rain, as well as animals and debris that can cause blockages.

- Ensure Proper Sizing: Your liner must be correctly sized for the appliance it serves to ensure proper draft and prevent condensation or overheating issues.

Have questions or need to schedule an inspection? We’re here to help. For more information about our services, visit our contact page.

Gerrior Masonry & Landscape Construction Corp. is based in Woburn, MA, and proudly serves homeowners throughout Middlesex and Essex County, Massachusetts.

Secure Your Home with Expert Chimney Services

Trust the Professionals for Peace of Mind

Your chimney liner is a critical safety component that silently protects your home and family. Ignoring signs of damage like smoke in your room or debris in your firebox can lead to devastating consequences, including house fires and carbon monoxide poisoning. Timely chimney liner repair is not a luxury—it’s a necessity.

Regular inspections and professional repairs are the most effective way to ensure your chimney operates safely and efficiently. For over 30 years, Gerrior Masonry & Landscaping has been a trusted name in masonry services across Massachusetts. Our commitment to quality craftsmanship and owner oversight on every project ensures your home is treated with the care it deserves. We have seen the damage that a neglected liner can cause and have helped countless homeowners restore safety and peace of mind.

If you suspect an issue with your chimney or it’s been a while since your last inspection, don’t wait. The cost of inaction is far greater than the investment in a professional repair. Your home and family deserve the protection that a safe, functional chimney system provides.

Based in Woburn, MA, Gerrior Masonry & Landscape Construction Corp. proudly serves homeowners and businesses throughout Middlesex and Essex County, Massachusetts.

More info about chimney repairs