Paver Driveway Installation: Top 5 Secrets

Why Paver Driveway Installation Creates Lasting Value

A paver driveway installation transforms one of your home’s most visible features, delivering decades of durability and curb appeal. This comprehensive process involves careful planning, excavation, base preparation, and precise paver placement to create a surface that can handle New England’s harsh winters and heavy traffic.

Essential Steps for Paver Driveway Installation:

- Planning & Design – Measure area, choose pavers, obtain permits

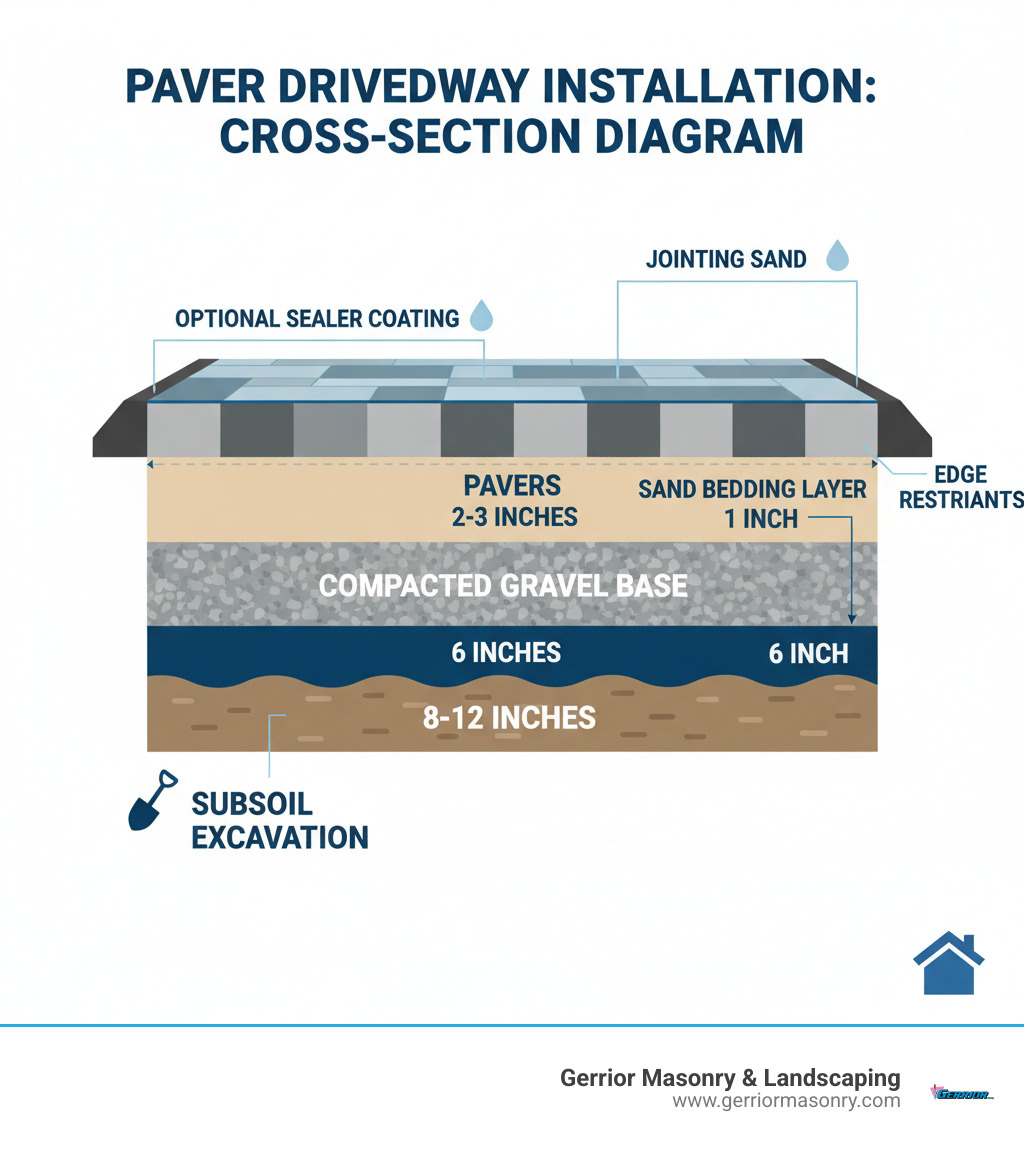

- Excavation – Dig 8-12 inches deep, grade for drainage

- Base Preparation – Layer and compact crushed stone foundation

- Sand Bedding – Level 1-inch sand layer for paver placement

- Paver Installation – Lay pavers with proper spacing and alignment

- Finishing – Install edge restraints, fill joints, compact surface

- Sealing – Apply protective sealant for longevity

The installation process typically takes 3+ days with a professional crew and costs between $10-$70 per square foot based on materials and complexity. A properly installed paver driveway can last up to 30 years with minimal maintenance.

“Installing pavers requires patience, planning, and elbow grease,” but the results speak for themselves. Unlike concrete or asphalt, individual pavers can be replaced if damaged, and the interlocking design distributes weight evenly to prevent cracking.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp., and I’ve been perfecting paver driveway installation techniques for over 34 years throughout Massachusetts. My team has transformed countless driveways using proven methods that ensure both beauty and structural integrity.

Related content about paver driveway installation:

The Complete Guide to Paver Driveway Installation

Changing your home with a beautiful and durable paver driveway is a significant undertaking, but one that offers immense rewards. This section will walk you through everything from planning to completion, ensuring a durable and beautiful result.

Why Choose Pavers? Benefits & Costs

Choosing pavers over traditional asphalt or concrete is a smart investment in your home’s value and curb appeal. Key benefits include:

- Durability and Longevity: Pavers handle heavy traffic and harsh weather, flexing with the ground to resist cracking from New England’s freeze-thaw cycles. A properly installed paver driveway can last 30 years or more.

- Easy Repairs: Unlike large slabs of concrete or asphalt, damaged individual pavers can be lifted and replaced, keeping long-term maintenance costs low.

- Design Flexibility: With endless shapes, colors, and textures, pavers allow for custom designs that match your home’s style and significantly boost curb appeal.

- Superior Drainage: Permeable paver systems allow water to drain through the joints, reducing runoff and puddling.

While the initial investment is higher than asphalt, the long-term benefits are substantial. These are average costs based on internet data and not actual costs for Gerrior Masonry services, but you can expect to pay between $10 to $70 per square foot installed. For a typical driveway, this can range from $4,800 to $19,200. The durability, ease of repair, and boost in property value make it an investment that pays dividends.

For more detailed information on the financial aspects, explore our page on the Cost of Paver Driveways.

Planning Your Paver Driveway Installation: Materials, Tools, and Paver Choice

Meticulous planning is essential for a successful paver driveway installation.

Essential Tools and Materials

A professional installation requires specialized equipment, but a DIY project needs at least:

- Excavation & Spreading: Shovel, rake, wheelbarrow

- Layout & Leveling: Tape measure, stakes, string line, 4-6 ft level, screed guides

- Compaction & Installation: Heavy-duty plate compactor, rubber mallet, push broom

- Cutting & Safety: Masonry saw (wet saw recommended), eye/hearing protection, gloves

Key materials include your chosen pavers, crushed stone base, bedding sand (coarse ASTM C33 sand or 1/8″ chip stone), edge restraints, and jointing sand (polymeric sand is recommended). Geotextile fabric is also advised for clay soils to separate the base from the subsoil.

Choosing Your Pavers: Style Meets Function

Your paver choice impacts the look and performance of your driveway.

- Concrete Pavers: Versatile, durable, and cost-effective. The most common choice.

- Brick Pavers: Offer a classic, timeless aesthetic with enduring charm.

- Natural Stone Pavers: Granite, bluestone, or cobblestones provide unique elegance but are typically more expensive.

- Porcelain Pavers: A sleek, contemporary option, but ensure they are rated for vehicular traffic.

When choosing, consider your home’s style, color, and the load-bearing needs of a driveway—pavers should be at least 2.5 to 3 inches thick. For a deeper dive into the options, visit our guide on Types of Pavers for Driveways.

Preparing the Foundation: The Most Critical Step

The foundation is the most critical part of your paver driveway. A paver driveway is only as good as its foundation.

Site Preparation and Excavation

- Call 811 Before You Dig! This free, mandatory service marks underground utility lines to prevent dangerous and costly accidents. Visit Call 811 before you dig.

- Mark the Area: Use stakes and string to outline the driveway. The base should extend 6-12 inches beyond the paved edge.

- Excavate: Dig to a depth of 8 to 12 inches for a standard driveway to allow for a proper base. For permeable systems, excavate to a minimum of 15 inches. Remove all grass and roots.

Creating Proper Drainage

Properly managing water is essential. Ensure your driveway slopes away from your home’s foundation.

- Slope: A slope of 1% to 2% (about 1/8 inch drop per linear foot) is required for effective drainage. Use string lines and a level to set this grade.

- Drainage Systems: For properties with significant water issues, consider integrating catch basins or French drains. Learn more about these solutions on our Drainage Systems & Dry Wells page.

Layering and Compacting the Gravel Base

The gravel base provides structural support.

- Lay Base in Lifts: Spread the crushed stone base in layers (lifts) of no more than 3-4 inches at a time.

- Compact Each Layer: Use a heavy-duty plate compactor to thoroughly compact each lift before adding the next. Lightly misting with water can help.

- Total Depth: Continue until you achieve a total compacted base depth of 8 to 12 inches. The goal is a dense, interlocked base. Avoid using plastic sheeting underneath, as it traps water.

The Paver Driveway Installation Process: Laying and Finishing

With a solid base prepared, you can begin laying the pavers.

Laying and Leveling the Bedding Layer

- Spread Bedding Material: Apply a 1-inch layer of coarse sand or 1/8″ chip stone over the compacted base.

- Screed the Layer: Use screed guides (pipes or 2x4s) and a straight board to pull the material across, creating a perfectly smooth, level surface.

- Do NOT Compact: The bedding layer should remain loose to allow the pavers to settle in during final compaction.

Laying the Pavers

- Start from a Corner: Begin laying pavers from a corner or a long, straight edge, working outwards. Use string lines to keep rows straight.

- Place, Don’t Slide: Set each paver straight down into the bedding sand. Pull from multiple bundles at once to ensure a natural color blend.

- Choose a Pattern: Simple, interlocking patterns like herringbone are best for driveways as they distribute weight effectively. For more ideas, see our Paver Driveway Design Ideas.

Edge Restraints, Cutting, and Compaction

- Install Edge Restraints: Secure plastic, metal, or concrete restraints around the perimeter on top of the compacted base to prevent pavers from shifting.

- Cut Pavers: Use a masonry saw with a diamond blade to cut pavers for edges and curves. Always wear proper safety gear.

- Compact the Pavers: Run a plate compactor (with a protective pad) over the entire surface at least 3 times to set the pavers into the bedding sand and create a smooth, level surface.

Joint Filling

- Spread Jointing Sand: Cover the surface with coarse sand or polymeric sand.

- Sweep into Joints: Use a push broom to sweep the sand into all the gaps until they are completely full.

- Final Compaction: Run the compactor over the driveway one last time to settle the sand. If using polymeric sand, follow the manufacturer’s instructions for activation, which typically involves a light mist of water.

Advanced Topics: Permeable Pavers and Maintenance

Consider these advanced options for improved performance and longevity.

Permeable Pavers: A Sustainable Choice

Permeable pavers are an eco-friendly option that allows rainwater to drain through the surface, reducing runoff and replenishing groundwater. The installation differs significantly from standard pavers, requiring a much deeper excavation (15+ inches) and specialized layers of washed, open-graded stone for the base. Due to this complexity, professional installation is highly recommended for permeable driveways.

Maintaining Your Paver Driveway

A little maintenance will keep your driveway looking great for decades.

- Routine Cleaning: Regularly sweep or blow off debris. Pressure wash on a low setting every few years.

- Weed Control: Pull weeds by hand or use an appropriate herbicide. Keeping joints filled with sand helps prevent growth.

- Re-sanding Joints: Every 3-5 years, sweep more jointing sand into the gaps to maintain the interlock.

- Sealing: Applying a quality sealer every 3-5 years is recommended to protect against stains and UV fading.

For more comprehensive tips, refer to our dedicated page on Paver Driveway Maintenance.

Common Issues and When to Call a Professional

Even with careful work, issues can arise. Here’s what to look for and when to call a pro.

Common Troubleshooting Issues

- Sinking or Uneven Pavers: Almost always caused by an inadequate or poorly compacted base.

- Weeds in Joints: Occurs in damp, shady areas. Regular cleaning and keeping joints full helps.

- Shifting Edges: Indicates that edge restraints have failed and need to be re-installed or reinforced.

- Puddling: A sign of improper slope or poor base drainage.

DIY vs. Professional Installation

While a small walkway might be a feasible DIY project, a driveway is a massive undertaking. The heavy excavation, large volume of materials, and need for specialized compaction equipment make it a job best left to professionals. Ensuring the correct base depth (8-12 inches), proper compaction, and a precise drainage slope are details that require an expert eye. A professional crew can complete the job in a few days, whereas it could take a DIYer weeks. For a project of this scale, hiring a professional is a wise investment in your home’s long-term value. For more reasons to consider professional help, see Why Choose Us for Your Paver Driveway.

Transform Your Driveway with Expert Installation

Congratulations! You now have a comprehensive overview of what a paver driveway installation entails. It’s a significant project, but one that delivers incredible returns in curb appeal, durability, and property value.

While a DIY approach is technically possible, the reality is that installing a driveway is a massive undertaking. The heavy excavation, precise grading, and specialized equipment required are often beyond the scope of a weekend project. For a flawless, long-lasting result, professional installation is the wisest investment. You’re not just paying for labor—you’re investing in experience, efficiency, and the peace of mind that comes with a warranty.

For homeowners in Middlesex and Essex County, Massachusetts, Gerrior Masonry & Landscaping has been perfecting the art of paver driveway installation for over 30 years. Our commitment to owner oversight on every project ensures that every detail, from the foundation to the final paver, is perfect. We have the expertise to handle any site condition and bring your vision to life.

Ready to transform your home’s entrance with a stunning paver driveway? Gerrior Masonry & Landscape Construction is based in Woburn, MA, and services Middlesex and Essex County, Massachusetts. Contact us for a professional driveway consultation and let’s build something that lasts.