Stone veneer installation: 4 Steps to Pro Results

Transform Your Home’s Exterior with Professional Stone Veneer

Stone veneer installation is a proven way to boost your home’s curb appeal and value. This lightweight alternative to full stone offers the same stunning aesthetic at a fraction of the cost and complexity, adding natural beauty to any exterior wall.

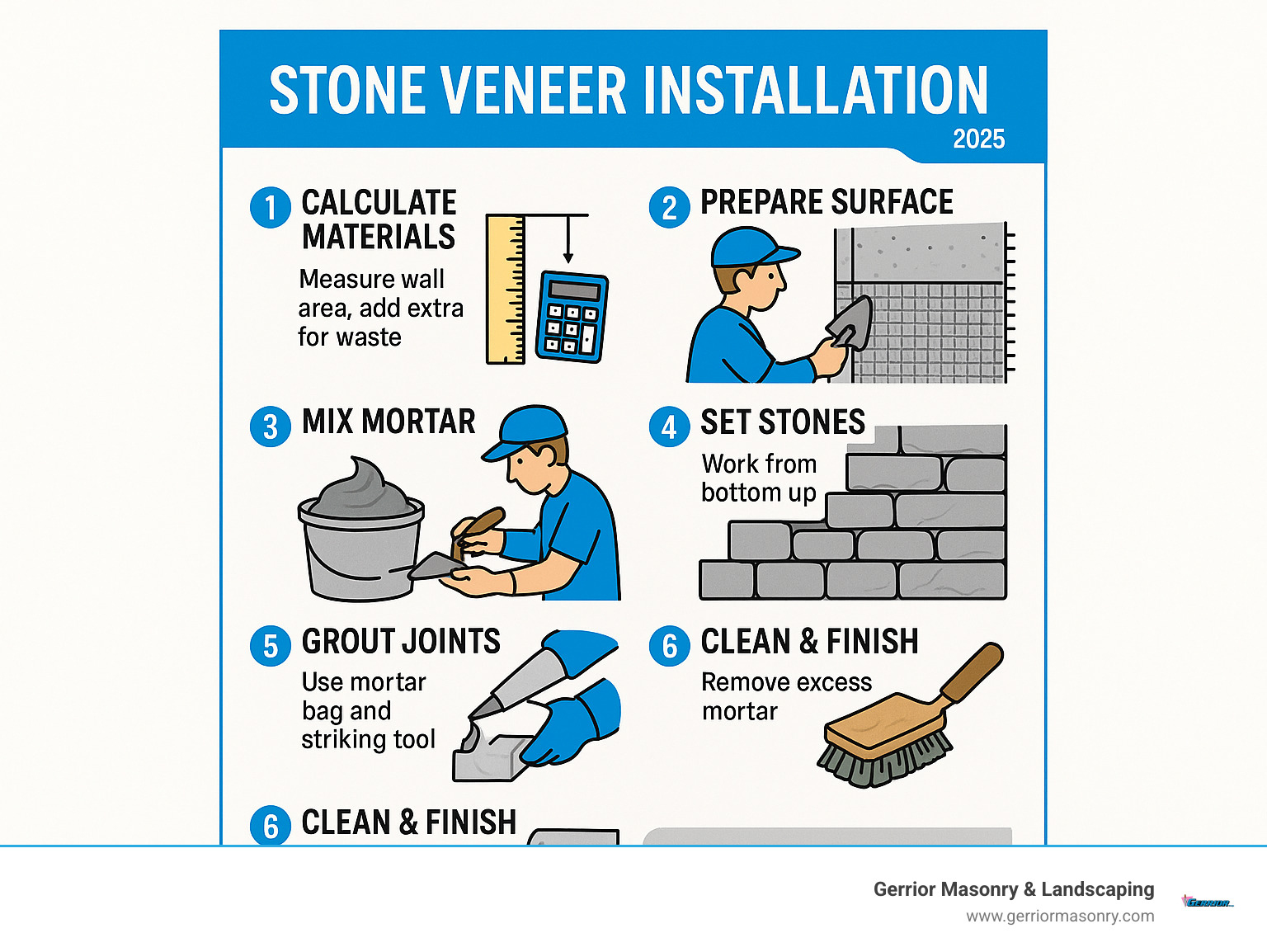

Essential Steps for Stone Veneer Installation:

- Calculate Materials: Measure the area, subtract openings, and add 10-15% for waste.

- Prepare Surface: Install a weather barrier, metal lath, and a scratch coat.

- Mix Mortar: Use Type S mortar with the proper consistency.

- Set Stones: Work from the bottom up, buttering the backs completely and pressing firmly.

- Grout Joints: Fill with a mortar bag and tool when “thumbprint hard.”

- Clean & Finish: Remove excess mortar and brush the surface clean.

The average cost for stone veneer materials ranges from $6-50 per square foot, with professional installation adding another $10-30 per square foot. These are average costs based on internet data and not actual costs for Gerrior Masonry services.

Depending on the material, stone veneer can last 25-100+ years. Natural stone offers superior longevity, while manufactured stone provides more options at a lower cost.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years of experience in Massachusetts, my team brings artistic vision and technical expertise to every project, ensuring your investment delivers lasting beauty and value.

Your Step-by-Step Guide to Stone Veneer Installation

This section details the complete process, from initial planning to the final touches, ensuring a professional-quality result for your project.

Planning & Preparation: Your Project Blueprint

Proper planning is the foundation for a successful stone veneer installation. This phase saves time, money, and future headaches.

Getting Your Material Calculations Right

First, calculate the total square footage of your walls (length d7 height). If you’re using corner pieces, you must account for them separately. Deduct 1 square foot of flat stone for each linear foot of corners you plan to install. Your mortar joint size (typically 1/2-inch) also affects the total amount of stone needed.

Choosing Between Natural and Manufactured Stone

Your choice of stone impacts budget, appearance, and installation.

| Feature | Natural Stone Veneer | Manufactured Stone Veneer |

|---|---|---|

| Material | 100% real stone, cut from quarries | Engineered from cement and aggregates |

| Weight | Heavier, may need structural support | Up to 75% lighter than real stone |

| Durability | Extremely durable, can last 100+ years | Very durable, typically lasts 25-70 years |

| Cost | Higher material and installation cost | More cost-effective |

| Appearance | Unique, natural variations | Consistent color and texture |

Tools and Materials You’ll Need

Having the right equipment is crucial. For tools, you’ll need a tape measure, level, chalk line, notched trowel, skill saw with a diamond blade, and a grout bag. Safety glasses, a dust mask, and work gloves are non-negotiable. For materials, you’ll need your stone veneer (flats and corners), a weather-resistant barrier, corrosion-resistant metal lath, galvanized fasteners, and Type S mortar.

What This Project Will Cost

Stone veneer installation costs vary. Materials typically run $6 to $50 per square foot, with installation adding another $10 to $30 per square foot. For a full home exterior, prices can range from $85,000 to $120,000 for a 2,500-square-foot house. These are average costs based on internet data and not actual costs for Gerrior Masonry services. The good news is that stone veneer often adds about 90% of its cost back to your home’s value.

If you’re thinking about changing more of your outdoor space, check out our hardscaping services for complementary improvements.

Surface Prep: The Key to a Lasting Installation

The prep work determines whether your project lasts 5 years or 50. It’s the most critical step for a professional result.

Suitable Base Surfaces

Stone veneer needs a solid base like framed walls with sheathing, clean concrete, or existing stucco. Avoid applying it directly over painted surfaces (especially oil-based), loose materials, or wallpaper, as these prevent a strong bond.

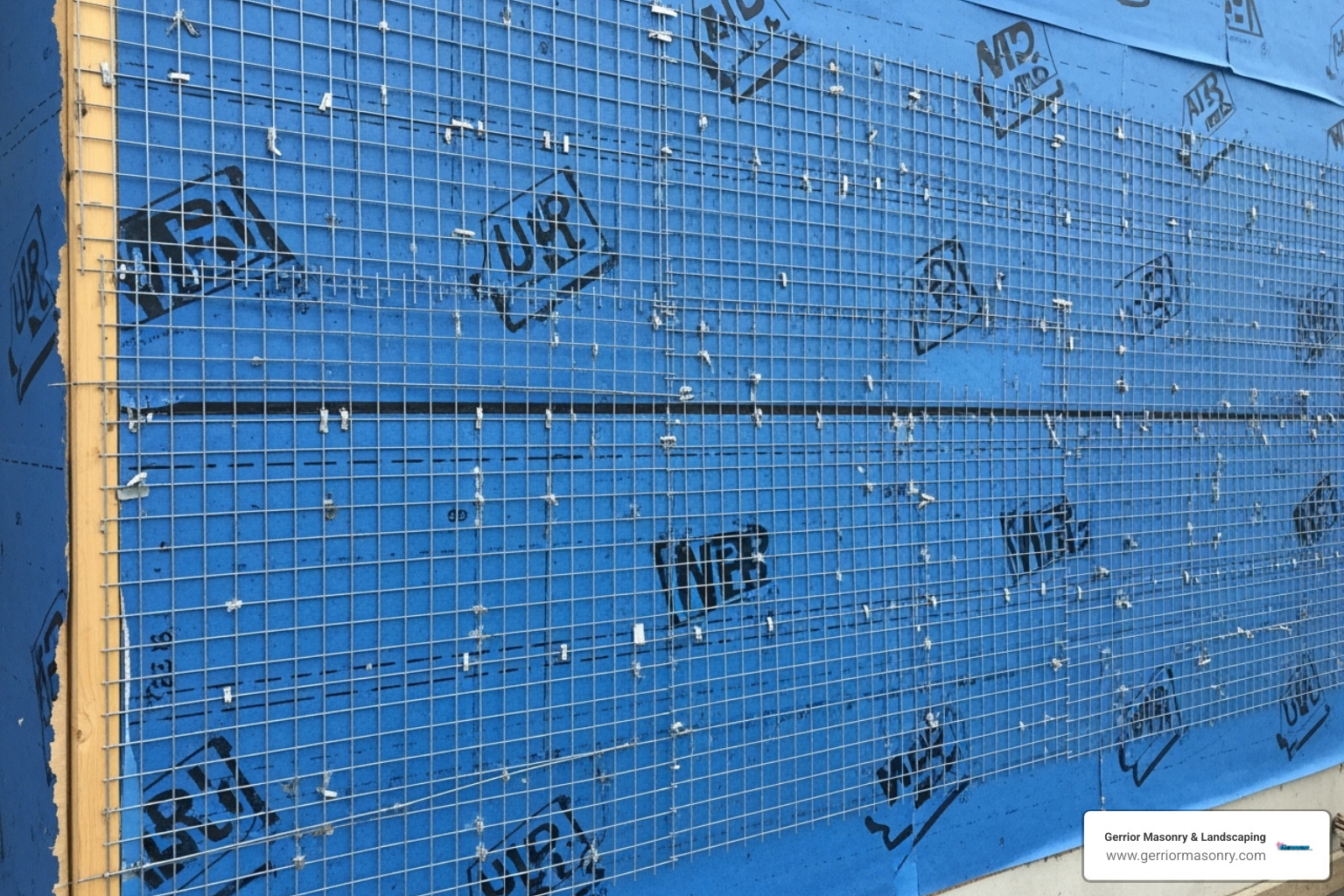

Water Management is Essential

Proper water management is non-negotiable. For exterior walls, this starts with installing two layers of Grade D building paper or house wrap shingle-style (bottom to top) with proper overlaps (4″ horizontal, 6″ vertical).

Over the barrier, attach corrosion-resistant metal lath with galvanized fasteners that penetrate the studs. The lath acts as a skeleton for the mortar. Ensure it’s overlapped correctly and wrapped tightly around corners.

Applying the Scratch Coat

A scratch coat—a 1/2-inch layer of Type S mortar—is applied over the metal lath. This coat completely covers the lath and provides a rough surface for the stone to bond to. After applying, rake horizontal grooves into the surface and let it cure for at least 24 hours before setting stone.

For visual guidance, the Installation and Technical Videos | Cultured Stone resource offers excellent demonstrations.

Adhering to Building Codes

Always check local building codes, which specify requirements for bond strength and clearances (e.g., 4 inches from grade). Following code ensures your installation is safe and durable.

Mortar & Stone Setting: Bringing Your Vision to Life

This is where your vision becomes reality. Technique and patience are key to a beautiful, long-lasting result.

Mixing and Applying Mortar

Use a pre-blended, polymer-fortified Type S mortar mixed to a thick, peanut butter-like consistency. Before applying, lightly dampen the back of absorptive stones to prevent them from drying the mortar too quickly. Apply a 1/2-inch to 1-inch layer of mortar to the entire back of the stone—this is called “buttering.” 100% coverage is critical to prevent moisture traps.

Stone Setting Strategies

First, lay out several boxes of stone to plan your pattern, mixing sizes and colors for a natural look. Install corner pieces first, alternating the long and short ends. Then, work from the bottom of the wall up to prevent mortar drips on finished work.

Press each stone firmly into the mortar with a slight wiggling motion until mortar squeezes out around the edges, confirming a solid bond. Once set, do not move the stone, as this will break the bond.

Handling Cuts and Corners

Use a skill saw with a diamond blade for large cuts and mason’s nippers for small adjustments, always wearing safety gear. For inside corners, butt flat pieces together. For outside corners, use the pre-formed pieces. Always turn cut edges inward or away from sightlines for the most authentic look.

Our masonry expertise extends beyond stone veneer. Learn more about our chimney repairs.

Finishing Touches: Grouting, Cleaning, and Avoiding Mistakes

The final steps are what separate amateur work from a professional stone veneer installation.

Grouting and Cleaning

Wait 24-48 hours after setting the stone before you begin grouting. Use a grout bag to apply Type S mortar into the joints, ensuring you fill all voids. When the grout is “thumbprint hard,” use a jointing tool to compact and smooth the mortar for a clean, recessed look.

Clean any wet mortar off stone faces immediately with a damp sponge and clean water. After grouting, use a soft brush to sweep away loose particles. Never use harsh chemicals or a pressure washer on new veneer.

Avoiding Costly Mistakes

With over 30 years of experience, we know what pitfalls to avoid. Steer clear of these common errors:

- Improper Surface Prep: Skipping the weather barrier or using inadequate fasteners will lead to failure.

- Poor Water Management: Insufficient clearances from the ground or improper flashing causes moisture damage.

- Inconsistent Joints: This detracts from the appearance and can compromise structural integrity.

- Working Top-Down: This can cause stones to slide and break their bond.

- Ignoring Building Codes: This can lead to unsafe installations and costly rework.

Understanding proper masonry techniques is key. See how attention to detail matters in our foundation repointing work.

Maintaining Your Masterpiece & When to Call the Experts

Your stone veneer installation is complete, and the results are stunning. But like any worthwhile investment, proper care ensures your stone veneer continues to improve your home’s beauty for decades to come. While smaller projects might be perfect for the ambitious DIY enthusiast, larger or more complex installations truly benefit from professional expertise.

Post-Installation Care and Maintenance

Routine Cleaning and Inspection

Stone veneer is low-maintenance. For most dirt, a simple rinse with a garden hose is sufficient. For stubborn spots, use a soft-bristled brush and clean water. Avoid pressure washers and harsh chemicals, which can damage the stone and mortar.

Periodically inspect your veneer for cracks or loose stones, especially after severe weather. While hairline cracks can be normal, larger ones may signal underlying issues. Also, look for efflorescence—a white, powdery residue that can usually be removed with a stiff brush and water.

Sealing and Longevity

Most stone veneer does not require sealing. In fact, sealing manufactured stone can void the warranty. Natural stone rarely needs it unless it’s in an area with constant moisture. If you do seal, use a high-quality breathable (silane- or siloxane-based) product.

With proper installation, natural stone veneer can last over 100 years, while high-quality manufactured stone typically lasts 25 to 70 years.

Why Trust a Professional for Your Stone Veneer Installation?

While some smaller projects are suitable for DIY, a professional stone veneer installation is crucial for complex jobs to ensure safety, durability, and a flawless finish.

Professionals understand the nuances of:

- Project Complexity: Managing flashing around windows, transitions between materials, and architectural details requires experience.

- Code Compliance: We stay current on all local building codes for structural integrity and moisture management, protecting your investment.

- Water Management: This is the #1 cause of veneer failure. Expertise in weather-resistant barriers, weep screeds, and drainage planes is essential for a long-lasting installation.

At Gerrior Masonry & Landscaping, Joe Gerrior brings over 30 years of hands-on experience to every project. Our owner-led approach guarantees attention to detail that larger companies can’t match. We combine artistic vision with technical precision to build lasting value into your property.

Ready to transform your home with the timeless appeal of stone veneer? Contact us today for a consultation on your masonry services needs.

Gerrior Masonry & Landscape Construction is based in Woburn, MA, and proudly serves Middlesex and Essex County, Massachusetts.