Introduction to the Building Blocks of Construction

Concrete blocks, also known as concrete masonry units (CMUs) or cinder blocks, are a cornerstone of modern construction. Made from a mixture of cement, water, and aggregates like sand and gravel, these versatile blocks have been used for over a century in everything from foundations to decorative walls.

Concrete block construction really took off in the early 1900s, when companies like Besser began developing standardized block-making machines. That shift from handmade blocks to machine-made units gave builders consistent sizes and shapes, which dramatically sped up construction and improved quality. Today, when masons talk about a “Besser block,” they are generally referring to the familiar rectangular CMU used in countless homes, commercial buildings, and landscape walls.

Because concrete blocks are modular and uniform, they fit together like building bricks for full-sized structures. This makes them ideal for New England projects where speed, strength, and durability are all critical, especially in freeze-thaw conditions and along sloped properties that need retaining walls.

Quick Facts About Concrete Blocks

- Standard US Size: 16″ x 8″ x 8″ (nominal dimensions)

- Actual Size: Typically 15 5/8″ x 7 5/8″ x 7 5/8″ to allow for mortar joints

- Weight Range: 25-50 lbs, depending on materials and whether they are hollow or solid

- Strength: Compressive strength typically ranges from 500 to 5,000 psi

- Common Uses: Foundations, retaining walls, building walls, steps, planters, and landscaping features

Concrete blocks are valued for their durability, fire resistance, and sound insulation. Their uniform size simplifies construction, and hollow cores can be used for reinforcement, making them a practical and economical choice for many projects.

In masonry work around Woburn and the surrounding Middlesex and Essex County communities, concrete blocks are especially popular for basement wall repairs, bulkhead replacements, and structural retaining walls that must handle heavy snow, water, and soil pressure.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years of experience, my team and I have used concrete blocks in countless foundation repairs, retaining walls, and hardscaping projects throughout Massachusetts. Understanding the basics of these materials is the first step to a successful project.

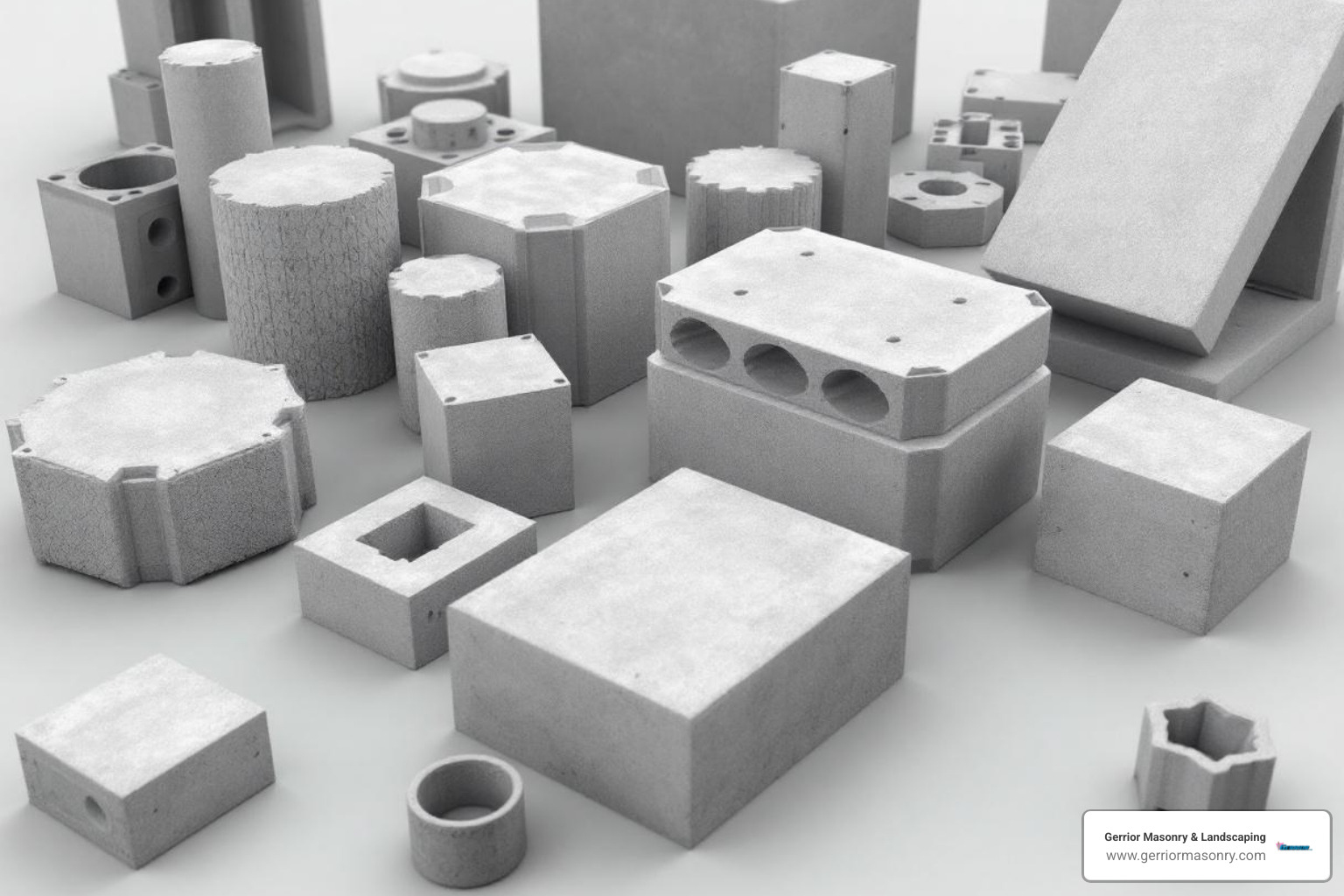

The infographic above highlights the basic anatomy of a standard hollow block: the outer shells that form the faces, the internal webs that add strength, and the cores (or cells) that can be left open for insulation or filled with concrete and rebar for added structural performance. Knowing these parts helps you understand how a simple block can become a strong, reinforced wall when installed correctly.

The Ultimate Guide to Concrete Blocks

Concrete blocks are more than just gray rectangles; they are engineered marvels. Understanding their composition, types, and uses is key to a successful project.

In residential and commercial work across towns like Lexington, Andover, and Medford, choosing the right block often means the difference between a wall that lasts decades and one that cracks or leans after a few winters. The sections below break down how these blocks are made and how to select the right type for your job.

How Concrete Blocks Are Made

The creation of a concrete block is a precise process that turns simple raw materials into a durable building component.

- Ingredients: The basic recipe includes Portland cement (the binder), water (to activate the cement), and aggregates like sand and gravel (for bulk and strength). The type of aggregate determines the block’s weight and properties. Heavyweight aggregates create dense, strong blocks, while lightweight aggregates produce blocks with better insulation.

- Lightweight vs. Heavyweight Aggregates: Lightweight blocks often use aggregates such as expanded shale, clay, or slate. These units are easier to handle and can improve thermal performance, which is useful in finished basements, garages, or additions. Heavyweight aggregates like crushed stone or dense gravel produce blocks that are ideal for high-load foundations and retaining walls.

- Manufacturing Process: The ingredients are mixed to a stiff consistency, poured into molds, and compacted with vibration to remove air pockets. The “green” blocks are then moved to a kiln for steam curing, which hardens them and gives them their final strength.

- Quality Control: Modern block plants carefully control moisture, mix proportions, and curing time to ensure each block meets strength and dimensional standards. This consistency helps masons build straighter, stronger walls with fewer adjustments in the field.

- Innovations in Production: Many manufacturers now incorporate admixtures that improve workability, water resistance, or color, allowing blocks to blend more naturally with brick, stone, or existing structures.

For a more detailed look at this process, you can learn how blocks are made.

Understanding the Types, Sizes, and Strengths of Concrete Blocks

Concrete blocks come in a variety of forms to suit different needs.

- Hollow vs. Solid: Most blocks are hollow, which makes them lighter and allows for steel reinforcement (rebar) and concrete fill, greatly increasing wall strength. Solid blocks are heavier and denser, offering maximum compressive strength for applications requiring high load-bearing capacity.

- Load-Bearing vs. Non-Load-Bearing: Load-bearing blocks are engineered to support the weight of a structure, such as in foundations and main walls. Non-load-bearing blocks are used for partition walls or decorative features.

- Common Shapes: Besides the standard stretcher block, there are specialized shapes like corner blocks for clean corners and lintel blocks (U-blocks) for creating beams over doors and windows.

- Decorative Blocks: Options like split-face blocks mimic natural stone, while breeze blocks have open patterns for ventilation and style.

- Dimensions and Strength: The standard nominal size in the U.S. is 8x8x16 inches. Compressive strength can range from 500 to 5,000 psi, depending on the block’s design and materials. Higher strength is critical for structural work, such as the foundation repairs we perform. If you’re concerned about your foundation, learn more about cinder block foundation repair.

Below is a simple comparison of common block categories. These are general characteristics only; actual performance depends on the exact product and design:

| Block Type | Typical Weight Range | Typical Strength Range (psi) | Common Uses |

|---|---|---|---|

| Hollow Concrete | 25-40 lbs | 500-2,500 | Basement walls, garages, partitions |

| Solid Concrete | 35-50+ lbs | 1,500-5,000 | Foundations, load-bearing walls |

| Lightweight CMU | 20-35 lbs | 500-2,000 | Above-grade walls, veneers, infill |

In practice, a retaining wall in a place like Wakefield or Chelmsford might use hollow blocks with steel reinforcement and grout, while a heavily loaded foundation in Newton may call for denser, higher-strength units. A qualified mason will select the right combination for your soil conditions, drainage, and building design.

DIY Projects and Safety with Concrete Blocks

While concrete blocks are great for DIY projects like garden beds, fire pits, and outdoor benches, safety is crucial.

Popular homeowner projects include:

- Raised garden beds: Stacked blocks can form durable, straight-sided planting areas that resist rot and shifting.

- Outdoor benches: Blocks paired with wood or stone slabs create sturdy seating that stands up to weather.

- Simple fire rings: Non-combustible blocks can outline a small, code-compliant fire feature when allowed by local regulations.

These lighter-duty uses are generally appropriate for handy homeowners, provided local codes are followed. Anything that holds back soil, supports a structure, or affects your foundation should be left to a professional.

When to Call a Pro: For any load-bearing structure—including foundations, retaining walls, or home additions—professional installation is essential. A licensed mason ensures the work meets building codes, incorporates proper drainage, and is structurally sound. At Gerrior Masonry & Landscaping, we have over 30 years of experience in all types of masonry work, guaranteeing a safe and durable result.

Safety First:

- Wear PPE: Always use heavy-duty gloves, safety glasses, and steel-toed boots. A dust mask is critical when cutting to avoid inhaling silica dust.

- Lift Correctly: Bend your knees and lift with your legs, not your back. These blocks are heavy.

- Plan Your Layout: Dry-lay the first course to check alignment and fit before setting blocks in mortar.

- Mind the Weather: Mortar and concrete behave differently in extreme heat or cold. In New England, work should be planned to avoid freezing temperatures during curing.

- Work Smart: Keep your work area clear and use the right tools for the job.

Expert Masonry Solutions for Your Next Project

As we’ve seen, concrete blocks are a versatile and durable material for everything from strong foundations to beautiful landscape features. Their strength, fire resistance, and insulation properties make them an excellent choice for many projects.

Concrete blocks perform especially well in New England, where repeated freeze-thaw cycles, heavy rains, and seasonal snow loads can quickly reveal weaknesses in poorly built walls. Properly reinforced and drained block walls can protect basements, stabilize slopes, and create attractive outdoor spaces that add long-term value to your property.

However, the quality of the final structure depends on both the materials and the skill of the installer. While DIY projects can be rewarding, load-bearing walls, foundations, and retaining walls require professional expertise to ensure safety, longevity, and compliance with building codes.

At Gerrior Masonry & Landscaping, we bring over 30 years of experience to every project. Our skilled team, under the direct oversight of owner Joe Gerrior, specializes in using concrete blocks for foundation repair, retaining walls, and custom hardscaping. We understand the demands of the New England climate and build structures that last.

Whether you need to repair a failing cinder block foundation, replace a deteriorating bulkhead entry, or design a new block retaining wall to tame a steep backyard, professional planning and installation will protect your investment and help avoid costly repairs down the road.

For professional hardscaping and masonry projects that demand precision and durability, we invite you to explore our hardscaping services. Gerrior Masonry & Landscape Construction is based in Woburn, MA, and proudly services Middlesex and Essex County, Massachusetts.