Bulkhead Installation: Top 3 Secrets for Safe Success

Bulkhead installation serves as a critical improvement to any home, providing a seamless blend of safety and functionality. Whether you’re upgrading a cellar entrance or aiming to protect your property from elements, this straightforward process ensures durability and an aesthetically pleasing appearance. In just a few steps, you can transform spaces with the installation of bulkheads, which not only improve access but also offer essential protection against moisture and other environmental factors.

If you’re considering bulkhead installation, focus on key aspects to ensure a successful outcome:

- Prioritize safety by using high-quality materials.

- Ensure proper sealing to maintain functionality.

- Follow a step-by-step process for a seamless finish.

As the owner of Gerrior Masonry & Landscape Construction Corp., I, Joe Gerrior, bring over 34 years of expertise in bulkhead installation and other masonry services. With a commitment to excellence, my team and I ensure that every bulkhead installation project is handled with precision, enhancing both the safety and aesthetic appeal of your space.

Bulkhead installation terms simplified:

– bulkhead structural integrity

– repairing bulkhead washouts

– bulkhead construction cost

Understanding Bulkheads

Bulkheads are more than just doors to your cellar; they play a vital role in protecting your home and enhancing its structure. Let’s explore what makes them so important.

Purpose of Bulkheads

Bulkheads serve as a protective barrier, primarily designed to keep water and debris out of your basement or cellar. They also provide easy access to these areas, which can be crucial for maintenance or emergency situations. Think of them as the gatekeepers of your home’s foundation, ensuring everything beneath stays safe and dry.

Bulkheads as Retaining Walls

In some installations, bulkheads act like retaining walls. They help hold back soil and prevent erosion around your home. This is especially important if your house is on a slope or near a body of water. By stabilizing the soil, bulkheads protect your foundation from shifting, which can lead to costly repairs.

Erosion Control

Erosion can be a silent enemy, gradually wearing away the land around your home. Bulkheads combat this by providing a sturdy barrier that keeps the soil in place. This not only protects your property but also helps maintain the landscape’s natural beauty. Properly installed bulkheads are essential for long-term erosion control and can save you from future headaches.

Understanding the significance of bulkheads helps you appreciate their role in home maintenance. Whether you’re dealing with water management or soil stability, bulkheads are an essential component of a well-protected home.

Preparing for Bulkhead Installation

Before diving into the bulkhead installation process, it’s crucial to prepare adequately. Proper preparation ensures a smooth installation and helps avoid unexpected costs and delays. Here’s what you need to consider:

Inspection Fee

Before any installation begins, an on-site inspection is necessary. This inspection costs $472, but it’s worth noting that this fee is credited back to the project cost if you choose to hire the same company for the installation. This step is crucial as it helps identify any potential issues and ensures the installation process is custom to your home’s specific needs.

Materials

Choosing the right materials is key to a successful bulkhead installation. While bulkheads can be made from various materials like wood or fiberglass, steel is often preferred for its durability. Steel bulkheads, custom-made and painted to match your home’s exterior, provide long-lasting protection and aesthetic appeal. Investing in high-quality materials can prevent future maintenance issues and improve your home’s value.

Labor

Labor costs can vary depending on the complexity of the installation and the specific requirements of your home. Professional installation is highly recommended to ensure safety and quality. Skilled labor ensures that the bulkhead is installed correctly, minimizing the risk of leaks or structural issues. When budgeting, consider the expertise and experience of the installation team as a worthwhile investment in your home’s longevity.

Removal Costs

If you’re replacing an old bulkhead, consider the costs associated with its removal. This can include disposing of rusted bolts, old flashing, and other debris. Efficient removal is essential to prepare the site for the new installation. Hiring professionals for this task can save time and reduce the risk of damage to your property.

By thoroughly preparing for your bulkhead installation, you set the stage for a successful project that improves your home’s functionality and curb appeal. Next, we’ll guide you through the step-by-step process of installing a new bulkhead, ensuring every detail is covered for a seamless transition.

Step-by-Step Guide to Bulkhead Installation

Removing the Old Bulkhead

The first step in bulkhead installation is removing the existing bulkhead. This process involves several key tasks:

- Rusted Bolts: Begin by addressing any rusted bolts. These can be particularly stubborn, so using a combination of tools like wrenches and penetrating oil can help loosen them. Don’t hesitate to improvise if needed.

- Flashing: Use a nail puller and hammer to remove the old flashing from the wooden hatch frame and house siding. You’ll be glad to know that the new steel bulkhead comes with its own waterproof flashing, so preserving the old one is unnecessary.

- Demolition: With the flashing removed, proceed to demolish the old hatch frame. Use pry bars to carefully detach the rotted wooden side frames from the concrete foundation and remove the old doorway header from the house. Clean up any debris to prepare for the new installation.

Installing the New Bulkhead

With the old bulkhead out of the way, it’s time to install your new steel bulkhead. Here’s how:

- Foundation Plate: Position the foundation plate for the new steel bulkhead doors. Mark the spots for anchors and pre-drill them using a hammer drill with a carbide-tipped masonry bit. This ensures a secure fit.

- Steel Anchors: Align the foundation plate with the pre-drilled holes in the concrete foundation. Hammer in masonry anchors into each hole to firmly secure the plate. This step is crucial for stability.

- Steel Door Kit: Next, assemble the steel door kit. Start by positioning the right side plate against the house and securing it with screws. Attach the left side to the concrete foundation using more masonry anchors through pre-drilled holes.

- Doorframe: Finally, position and attach the door frame for the steel bulkhead. Ensure everything is square and operates smoothly before tightening the frame. Use self-tapping screws to secure the frame to the side panels.

By following these steps, you ensure a sturdy and reliable bulkhead installation that improves your home’s security and functionality.

Tips for Successful Bulkhead Installation

When it comes to bulkhead installation, the devil is in the details. Here are some essential tips to ensure your installation is successful and long-lasting.

Clean and Dry Installation

Always start with a clean and dry surface. Avoid using silicone, Teflon, or thread lubricants during installation. These substances can cause the gasket to slip out of place or not seal correctly. Think of it like installing a car windshield; over time, the rubber naturally vulcanizes to create a perfect seal without any additives.

Proper Gasket Placement

The placement of the gasket is crucial to preventing leaks. Always place the gasket on the flange side of the bulkhead, not on the nut side. This applies whether the installation is inside or outside the tank. If placed next to the nut, water can travel along the threads and cause leaks. Hand-tighten the gasket and then give it an additional 1/4 to 1/2 turn—no more.

Use of Thread Lubricant

For threaded bulkheads, it’s important to clean off any excess flashing from the threads and valleys. Use a stick or crayon-type thread lubricant specifically designed for PVC threads. Products like LA-CO’s PLASTO-JOINT STIK® are excellent choices. They’ve been used successfully for decades because they stay pliable and don’t tear or roll out of the threads like Teflon tape.

Remember: Teflon tape was never designed for use with PVC. Using the right lubricant ensures a better seal and long-lasting installation.

By following these tips, you can avoid common pitfalls and ensure a successful bulkhead installation that stands the test of time. Up next, we’ll tackle some frequently asked questions about bulkhead installations to help you further understand the process.

Frequently Asked Questions about Bulkhead Installation

What is the cost of bulkhead installation?

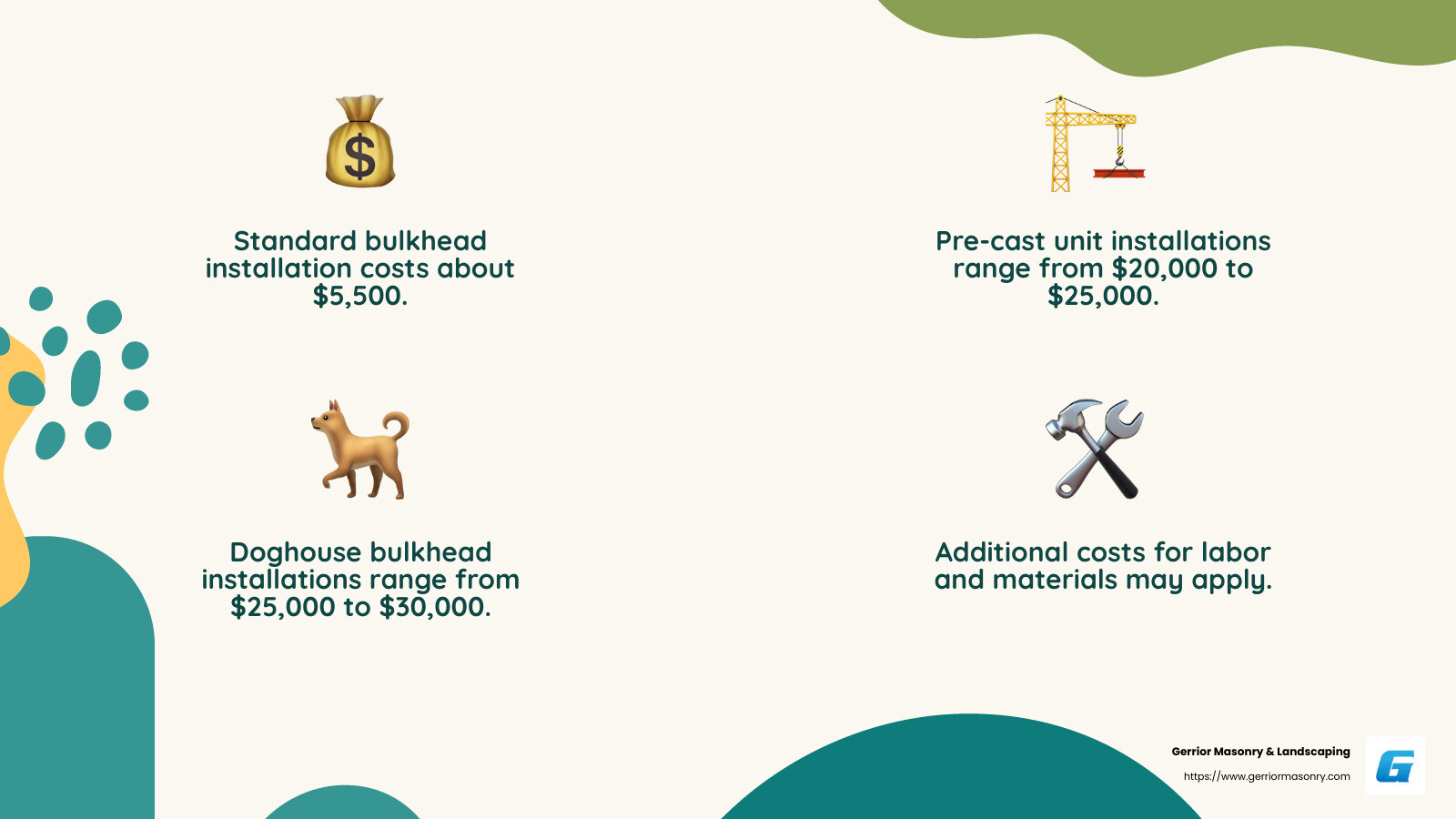

The cost of a bulkhead installation can vary significantly based on the type of bulkhead you choose. A standard bulkhead installation typically costs around $5,500. For more advanced options, like the all-in-one pre-cast unit, expect to pay between $20,000 and $25,000. If you opt for a doghouse bulkhead installation, the price ranges from $25,000 to $30,000. It’s important to consider that these prices might not include additional costs like labor or materials, so always ask for a detailed estimate.

How long does bulkhead installation take?

The time required for a bulkhead installation depends on several factors, including the complexity of the project and the type of bulkhead being installed. Typically, a standard installation might take a few days to complete. More complex installations, such as those involving custom designs or additional features, may take longer. It’s always a good idea to discuss timelines with your contractor to set realistic expectations.

Can I install a bulkhead myself?

While it might be tempting to save money by doing a bulkhead installation yourself, it’s generally not recommended. Bulkhead installations involve precise measurements, specialized tools, and expertise in masonry and structural integrity. Mistakes can lead to leaks, structural damage, or even safety hazards. Hiring professionals, like those at Gerrior Masonry & Landscaping, ensures that the job is done correctly and safely. Their expertise, quality materials, and custom approach make them a reliable choice for your bulkhead needs.

Conclusion

At Gerrior Masonry & Landscaping, we’re dedicated to providing custom solutions and delivering quality results for all your bulkhead installation needs. With over 30 years of experience in the industry, our skilled team is committed to ensuring that each project is completed with precision and care. Our hands-on approach, with owner oversight on every project, sets us apart, ensuring that every bulkhead we install is not only functional but also seamlessly integrated into your space.

We understand that every property is unique, which is why we offer custom solutions to meet your specific requirements. Whether you’re dealing with erosion control, need a retaining wall, or want to improve the aesthetic appeal of your home, our team is here to guide you through the process.

Choosing a professional service like ours means you can trust that your bulkhead installation will be handled with the utmost attention to detail. From the initial consultation to the final touches, we prioritize your satisfaction and the longevity of our work. Our commitment to excellence ensures that your investment is protected, and your space is secure.

If you’re ready to transform your property with a new bulkhead, we invite you to learn more about our services. Contact us today and find how Gerrior Masonry & Landscaping can deliver the quality and custom solutions you deserve.