Bulkhead Structural Integrity: Top 3 Vital Tips 2024

When it comes to bulkhead structural integrity, understanding its role can make a significant difference in construction projects. Simply put, bulkheads are the unsung heroes of structural reinforcement. They serve as vertical walls that divide spaces while boosting a building’s sturdiness. Here’s the quick takeaway for anyone curious about their importance:

- Support and Stability: Bulkheads bolster the construction, enhancing its load-bearing capacity.

- Safety and Security: They provide resistance to both noise and fire.

- Space Division: Bulkheads effectively create and separate different areas within a building.

In the following sections, we’ll dive deeper into the importance of bulkhead design, installation, and materials. You’ll find why these structural giants are crucial for any construction project.

I’m Joe Gerrior, dedicated to ensuring that bulkhead structural integrity remains front and center in all our projects at Gerrior Masonry & Landscaping. With over 34 years of experience, I bring extensive knowledge and commitment to each task, ensuring that our structures are both aesthetic and robust.

Understanding Bulkhead Structural Integrity

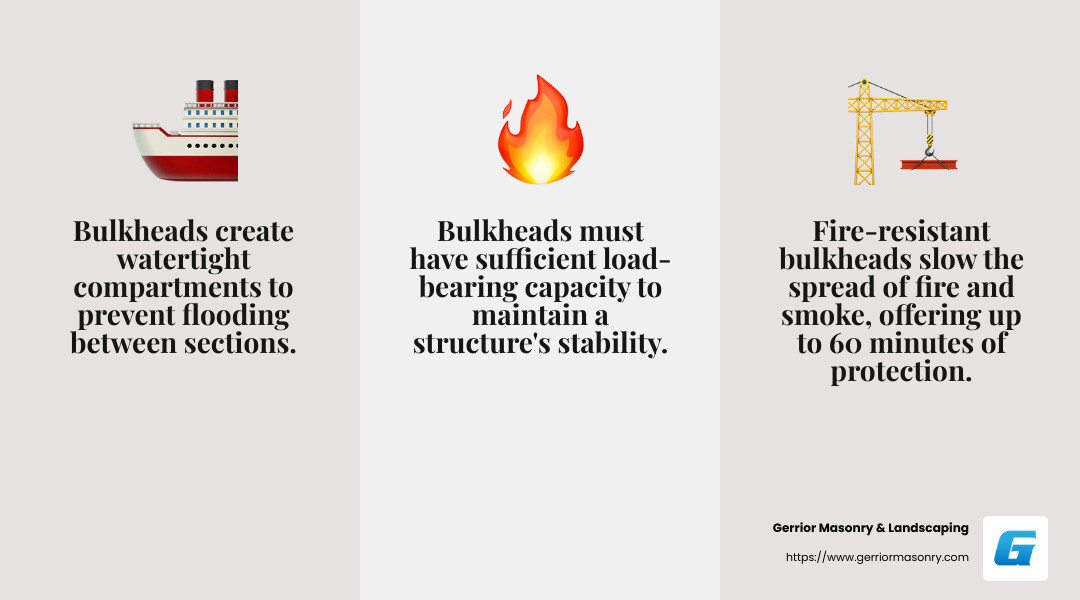

When it comes to bulkhead structural integrity, there are three key aspects to consider: watertight compartments, fire resistance, and load-bearing capacity. Let’s break these down.

Watertight Compartments

Bulkheads are essential in creating watertight compartments within a structure. This is particularly important in marine environments, like ships, where they help contain flooding. By dividing a vessel into smaller sections, bulkheads ensure that if one compartment takes on water, the others remain dry and buoyant. This compartmentalization can be a lifesaver, literally keeping the ship afloat during emergencies.

On land, watertight bulkheads protect against moisture intrusion in basements or other below-ground structures. This prevents water damage and maintains the integrity of the building.

Fire Resistance

Another critical function of bulkheads is their ability to resist fire. Fire-resistant panels are integrated into bulkheads to slow the spread of flames and smoke. According to SOLAS regulations, bulkheads are classified based on their fire-resistance capabilities. Class-A panels, for example, can prevent fire and smoke from passing through for up to 60 minutes, depending on the specific type (A-60, A-30, etc.).

This feature is crucial in both maritime and terrestrial applications, providing valuable time for evacuation and fire-fighting efforts.

Load-Bearing Capacity

Bulkheads are not just passive barriers; they actively support the structure. By carrying loads and distributing weight, they improve the building’s overall stability. In ships, bulkheads help maintain the vessel’s shape and prevent deformation. On land, they contribute to the load-bearing framework, supporting floors and roofs.

Incorporating strong materials like steel or concrete increases the load-bearing capacity of bulkheads, ensuring they can withstand significant pressure and weight. This strength is vital for maintaining the structural soundness of both buildings and ships.

In summary, bulkhead structural integrity is a multifaceted concept that encompasses watertightness, fire resistance, and load-bearing capacity. Each aspect plays a vital role in ensuring the safety and durability of a structure, whether it’s at sea or on land.

Types of Bulkheads

Bulkheads are crucial components in both marine and terrestrial structures. They come in various types, each serving specific purposes. Let’s explore the three main types: transverse bulkheads, longitudinal bulkheads, and collision bulkheads.

Transverse Bulkheads

Transverse bulkheads run side to side across a ship or structure. They are primarily used to create watertight compartments. This design is significant in maintaining a ship’s buoyancy during flooding. By compartmentalizing the vessel, transverse bulkheads prevent water from spreading throughout the ship, allowing it to stay afloat even if one section is compromised.

These bulkheads also add strength to the ship’s hull, reducing deformation and absorbing racking stresses. This dual function makes transverse bulkheads indispensable for both safety and structural integrity.

Longitudinal Bulkheads

Longitudinal bulkheads extend along the length of a ship. They are often found within transverse bulkheads to further increase compartmentalization. This setup improves a ship’s buoyancy by isolating flooded sections more effectively, especially in large vessels like tankers.

Moreover, longitudinal bulkheads contribute to the ship’s longitudinal strength. They help maintain the vessel’s shape and integrity over long distances, making them essential for commercial and cargo ships.

Collision Bulkheads

Collision bulkheads are positioned at the forward part of a ship. Their primary role is to protect the vessel from flooding in the event of a collision. As per SOLAS regulations, these bulkheads must be watertight up to the bulkhead deck. The design ensures that even if the front of the ship is breached, the rest remains secure and operational.

To comply with safety standards, collision bulkheads have minimal openings. Any necessary openings, like those for pipes, are tightly controlled and equipped with remotely operated valves to maintain watertight integrity.

In summary, each type of bulkhead—transverse, longitudinal, and collision—plays a unique role in enhancing bulkhead structural integrity. They provide essential support, compartmentalization, and safety features critical for both ships and buildings.

Ensuring Bulkhead Structural Integrity

Bulkhead structural integrity is vital for the safety and durability of both marine and coastal structures. Let’s explore how soil stabilization, hydrostatic pressure management, and polymer injection are key to achieving this.

Soil Stabilization

One common cause of bulkhead failure is soil erosion behind the structure. When soil erodes, it weakens the foundation, making the bulkhead vulnerable to collapse. Soil stabilization is essential to prevent this. Traditionally, high-quality filter fabric was used to control erosion. However, some modern installations have cut corners with cheaper materials, leading to failures.

To combat this, contractors now use polymer injection techniques. By injecting specialized polymers into the soil, they can reinforce the weak points behind the bulkhead. This method not only stabilizes the soil but also seals leaks, providing a robust solution to erosion problems.

Hydrostatic Pressure Management

Hydrostatic pressure is the force exerted by water accumulating behind a bulkhead. If left unmanaged, this pressure can cause cracking, bulging, or even collapse. Managing hydrostatic pressure is crucial for maintaining bulkhead integrity.

A comprehensive approach involves creating dewatering channels and installing pressure control filters. These channels allow water to pass through without carrying soil with it, effectively reducing pressure on the bulkhead. Using polymer injection in these areas can further solidify the soil and prevent leaks, ensuring the structure withstands the forces of nature.

Polymer Injection

Polymer injection is a game-changer in modern bulkhead construction. This innovative technique involves injecting polymer materials into the soil and structure to reinforce weak points. The polymers used are resilient and can withstand environmental stresses better than some traditional materials.

By combining polymer injection with hydrostatic pressure management, contractors can address both soil erosion and pressure issues simultaneously. This dual approach significantly improves the bulkhead structural integrity, ensuring long-lasting protection.

Incorporating these advanced techniques into bulkhead construction not only improves structural soundness but also aligns with environmental safety standards. Using environmentally friendly polymers ensures that coastal protection efforts are sustainable and responsible.

Bulkhead Construction and Materials

When it comes to building bulkheads, choosing the right materials is crucial for ensuring structural integrity. The most common materials used in bulkhead construction are concrete, steel, and corrugated designs. Each has its own strengths and applications.

Concrete Bulkheads

Concrete is a popular choice for bulkheads due to its strength and durability. It is especially useful in environments where the bulkhead needs to withstand significant pressure, such as retaining walls or marine structures. Concrete bulkheads provide excellent load-bearing capacity and are often used in areas prone to erosion and hydrostatic pressure.

One of the main advantages of concrete is its ability to be molded into various shapes, allowing for custom designs. However, it requires proper waterproofing techniques to prevent water infiltration, which can lead to structural damage over time.

Steel Bulkheads

Steel bulkheads are known for their high strength-to-weight ratio. This makes them ideal for situations where a strong yet lightweight solution is needed. Steel bulkheads are commonly used in shipbuilding, providing essential support and compartmentalization within the vessel.

These bulkheads are also fire-resistant, which improves safety in case of emergencies. However, steel is susceptible to corrosion, especially in marine environments. To combat this, protective coatings and regular maintenance are necessary to ensure longevity.

Corrugated Bulkheads

Corrugated bulkheads are gaining popularity due to their unique design and ease of fabrication. The corrugated pattern provides additional strength, allowing these bulkheads to withstand significant pressures without the need for additional stiffeners. This makes them lighter and easier to install compared to traditional flat bulkheads.

In ships, corrugated bulkheads help reduce welded joints, which can be potential weak points. They also assist in preventing cargo accumulation by using shredder plates at the base. However, the uniform thickness of corrugated plates can increase the overall weight compared to conventionally stiffened bulkheads.

Incorporating these materials into bulkhead construction requires careful consideration of the specific needs of the project. Whether it’s the robust nature of concrete, the strength and flexibility of steel, or the innovative design of corrugated bulkheads, each material plays a vital role in maintaining bulkhead structural integrity.

These choices ensure that bulkheads not only support the structure but also improve its durability and safety, leading into the next section on frequently asked questions about bulkhead structural integrity.

Frequently Asked Questions about Bulkhead Structural Integrity

Are bulkheads crucial for structural support?

Yes, bulkheads are essential for providing structural support in both buildings and ships. While some bulkheads are non-structural components, they still contribute significantly to the overall rigidity of a structure. In ships, they help compartmentalize spaces, which improves stability and safety. By dividing the vessel into watertight compartments, bulkheads prevent water from flooding the entire ship if a breach occurs.

What is the life expectancy of a bulkhead?

The typical life expectancy of a bulkhead is around 25 years. However, this can vary depending on the materials used and the environmental conditions they face. Regular maintenance is key to extending the lifespan of a bulkhead. This includes inspecting for signs of wear, corrosion, or damage. Addressing these issues promptly ensures that the bulkhead continues to function effectively and maintains its structural integrity over time.

How do bulkheads contribute to ship safety?

Bulkheads play a critical role in ensuring ship safety through compartmentalization and buoyancy. By dividing the ship into separate, watertight sections, they can contain water ingress to localized areas, preventing the entire vessel from sinking in the event of hull damage. This compartmentalization improves buoyancy and stability, allowing the ship to remain afloat even if one section is compromised.

Properly designed and maintained bulkheads are vital for the safety of any maritime vessel, ensuring that it can withstand various pressures and conditions at sea.

Conclusion

At Gerrior Masonry & Landscaping, we understand the importance of maintaining structural soundness in all our projects, especially when it comes to bulkheads. These structures are crucial for coastal protection and are essential in both residential and marine environments. By ensuring that bulkheads are constructed and maintained properly, we help safeguard properties and vessels against the unpredictable forces of nature.

Our team is committed to using advanced techniques and high-quality materials to improve the structural integrity of bulkheads. From polymer injections for soil stabilization to comprehensive hydrostatic pressure control systems, we employ cutting-edge solutions to address common issues like erosion and pressure damage. This approach not only prolongs the life of bulkheads but also ensures they perform their vital roles effectively.

With over 30 years of experience, Gerrior Masonry & Landscaping is a trusted partner for bulkhead replacements and repairs. We pride ourselves on delivering high-quality results through skilled craftsmanship and meticulous oversight. Whether you need a new bulkhead installation or maintenance for an existing structure, our team is ready to assist.

For detailed information on our bulkhead services, visit our Bulkhead Replacement page. Let us help you ensure the structural soundness and coastal protection your property deserves.