Fireplace Caulk: Best Guide 2025

Why Choosing the Right Fireplace Caulk Matters

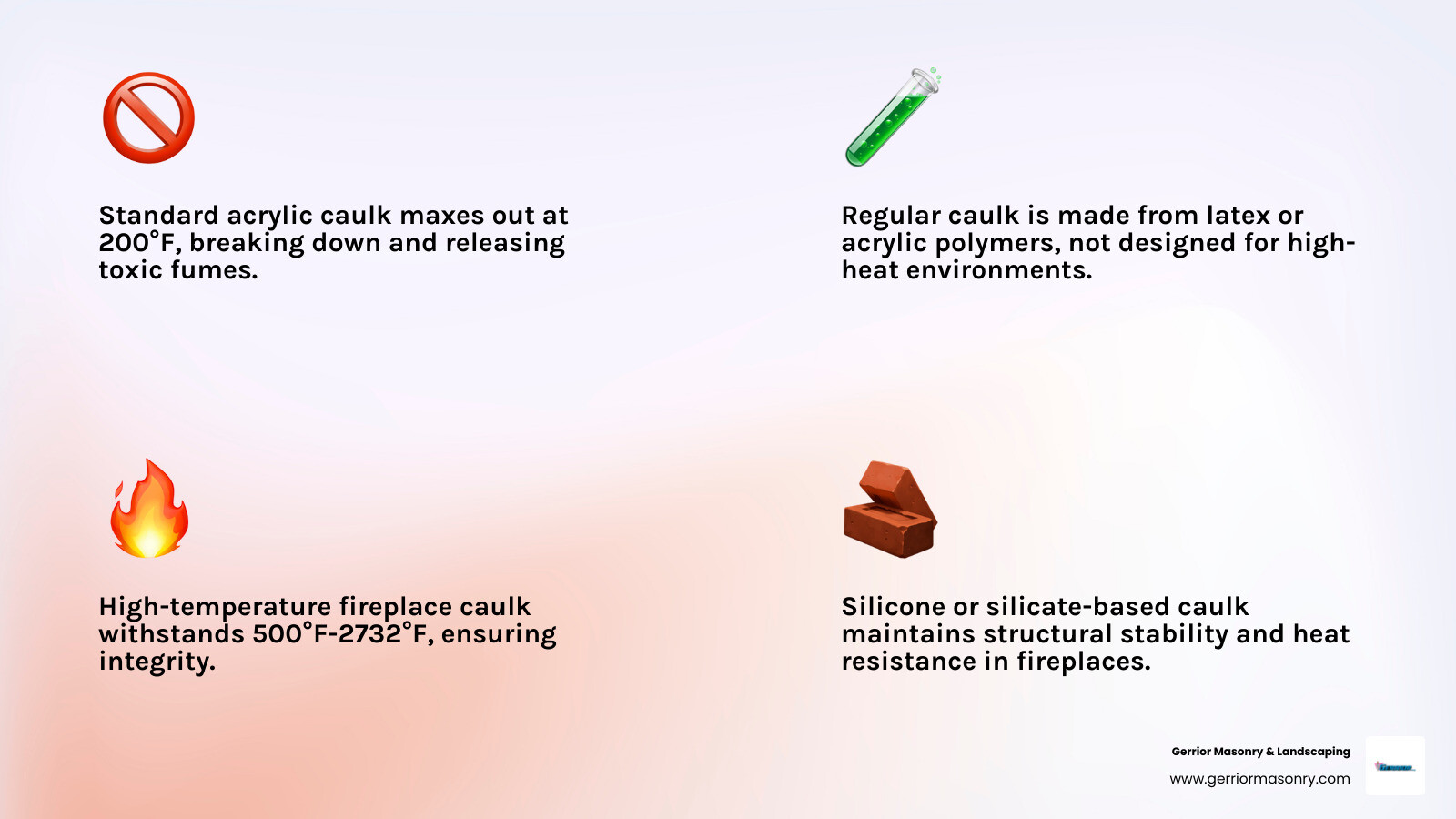

Many homeowners reach for a standard tube of all-purpose caulk for what seems like a minor crack around their fireplace, not realizing the significant risks involved. Fireplace caulk is not just another sealant; it’s a critical safety component, a specialized high-temperature formula engineered to withstand extreme heat without cracking, melting, or releasing toxic fumes. Using the correct sealant is absolutely crucial for the safety, efficiency, and long-term structural integrity of your fireplace and chimney system. While standard household caulk quickly fails and becomes a hazard above 200°F, true fireplace caulk is designed to maintain a durable, protective seal at continuous operating temperatures of 500°F and often much higher.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years in the masonry business here in Massachusetts, my team and I have repaired countless fireplaces where the wrong materials were used, leading to dangerous conditions and costly damage. We’ve seen firsthand how this single, often overlooked detail—the right sealant—is essential for any safe and functional fireplace repair.

Easy fireplace caulk word list:

What is Fireplace Caulk and Why is it Essential?

Fireplace caulk is a sealant specifically formulated to fill gaps and cracks in and around the high-heat areas of your fireplace, including the firebox, flue, and the perimeter of a fireplace insert. Its role is far more than cosmetic; it’s a fundamental component of a safe and efficient system. This is vital for several critical reasons:

- Safety: A complete, unbroken seal is your first line of defense against the leakage of dangerous combustion byproducts, including smoke and the odorless, colorless, and deadly gas, carbon monoxide (CO). Even a small crack can allow CO to seep into your living space, creating a serious health hazard. A properly sealed fireplace ensures that all fumes are directed safely up the chimney.

- Energy Efficiency: Gaps and cracks are two-way streets for air. They allow precious radiant heat from your fire to escape into the chimney cavity instead of warming your room. Simultaneously, they create pathways for cold drafts to enter your home, especially when the fireplace is not in use. Sealing these gaps can significantly improve your home’s comfort and help lower energy bills by reducing heat loss and preventing your heating system from working overtime.

- Structural Protection: Masonry is porous, and moisture is its greatest enemy. Fireplace caulk acts as a crucial barrier, preventing water and moisture from infiltrating the brick and mortar. This is especially important for the exterior chimney, where moisture can freeze and expand in a destructive cycle known as freeze-thaw damage. This process causes spalling (flaking) and deterioration of the masonry, leading to expensive and complex brick-fireplace-repair.

The growing homeowner awareness of these essential benefits is reflected in the specialty sealant market, with the global fireplace caulk sector projected to reach $1.8 billion by 2030.

The Dangers of Using the Wrong Sealant

Using a standard acrylic, latex, or all-purpose silicone caulk on a fireplace is not just a mistake—it’s a serious safety hazard. These common household products are not formulated for the thermal stress of a fireplace and will fail in dangerous ways, leading to:

- Fire Hazards: Standard caulks have a low combustion point. When exposed to the high radiant heat of a fire, they can soften, melt, and even ignite, providing a fuel source that can spread flames to adjacent combustible materials like a mantel or wall framing.

- Release of Toxic Fumes: As these non-rated caulks heat up and degrade, their chemical compounds break down. This process, known as off-gassing, can release a cocktail of hazardous chemicals and volatile organic compounds (VOCs) into your home’s air, posing a significant health risk to your family and pets.

- Rapid Material Degradation: The heat will cause the caulk to quickly become brittle, crack, char, and shrink away from the joint. This not only creates an unsightly, blackened mess but completely destroys the integrity of the seal.

- Complete Seal Failure: A degraded, shrunken seal is no seal at all. It re-opens the pathway for smoke, carbon monoxide, and cold drafts to enter your home, completely defeating the purpose of the repair and reintroducing the very dangers you were trying to prevent.

Key Features to Look for in a High-Temperature Sealant

When selecting a high-temperature sealant, it’s not enough to just grab one labeled “fireplace caulk.” You must match the product’s specifications to the exact location of the repair. Prioritize these key features:

- Temperature Resistance: This is the most critical factor. Check the product’s maximum continuous operating temperature. Use sealants rated for at least 500°F for sealing gaps around a metal insert or the outer edges of the firebox opening. For repairs inside the firebox or areas in direct contact with flames, you will need a refractory cement or mortar rated up to 2732°F (1500°C).

- Flexibility: Different materials expand and contract at different rates when heated (a principle known as the coefficient of thermal expansion). Metal fireplace inserts expand more than the surrounding masonry. A flexible, silicone-based caulk is essential for these joints to accommodate this movement without cracking and breaking the seal. Rigid cements would fail in these applications.

- Adhesion: The sealant must be formulated to create a tenacious bond with the specific materials of your fireplace. Look for products that explicitly state they adhere to non-porous surfaces like metal and glass, as well as porous masonry like brick, stone, and mortar.

- Color Options: While function is paramount, aesthetics matter. Most high-temperature caulks are available in colors like black, gray, almond, or buff, allowing you to choose one that blends seamlessly with your brick or mortar for a clean, professional-looking repair.

- Curing Time and Method: Curing is the chemical process by which the caulk hardens and achieves its final properties. Always follow the manufacturer’s instructions. Some products air-dry over 24-72 hours, while others require a specific heat-curing process (e.g., a series of small, progressively warmer fires) to fully harden and become heat-proof.

- Non-Combustible Properties: Verify that the product is rated as non-combustible and non-flammable. This ensures that the sealant itself will not act as fuel or contribute to the spread of a fire.

A Homeowner’s Guide to Choosing and Using Fireplace Caulk

Taking on a DIY fireplace project requires the right tools and knowledge. Proper preparation and application of high-temperature fireplace caulk are key to a safe and efficient outcome. Mastering this maintenance task can save you from larger issues down the road.

How to Properly Apply Fireplace Caulk

Follow these steps for a durable, effective, and safe seal:

- Gather Tools: You’ll need high-temperature caulk, a caulking gun, a utility knife, a wire brush, and a damp cloth.

- Prepare the Surface: The joint must be completely clean, dry, and free of dust, soot, or loose debris. Use a wire brush to remove old, failing material. A clean surface is essential for proper adhesion.

- Remove Old Caulk: Scrape away all traces of the old sealant using a utility knife or caulk removal tool.

- Prepare the Caulk Tube: Cut the nozzle tip at a 45-degree angle to a size slightly smaller than the gap. Puncture the tube’s inner seal.

- Load the Caulking Gun: Insert the caulk tube into the gun.

- Apply a Consistent Bead: Hold the gun at a 45-degree angle and apply steady pressure to lay a continuous bead that fills the gap.

- Tool the Joint: Immediately smooth the bead with a caulk tool or a gloved finger to ensure good contact and a neat finish. Wipe away excess with a damp cloth.

- Allow to Cure: Follow the manufacturer’s instructions for curing time before using the fireplace. Some products require heat to cure fully. Premature use will compromise the seal. For more complex jobs, consider our fireplace-cement-crack-repair services.

Types of High-Temperature Sealants

Different areas of your fireplace require specific types of caulk. Understanding their properties is key to a successful repair.

-

Silicone-Based High-Temperature Caulk:

- Description: A flexible sealant, often RTV silicone (Room Temperature Vulcanizing).

- Temperature Resistance: Typically withstands 500°F to 800°F.

- Applications: Ideal for sealing joints that experience movement, such as around fireplace inserts, stovepipes, and metal-to-masonry connections.

-

Silicate-Based Cements (Furnace Cement):

- Description: A non-flammable compound that cures to a rock-hard, rigid seal.

- Temperature Resistance: The highest heat resistance, with some products rated up to 2732°F (1500°C).

- Applications: Perfect for direct flame exposure. Use it to patch fire bricks and seal cracks in the firebox.

-

Refractory Mortars:

- Description: Cement-based compounds designed for joining and repairing fire bricks.

- Temperature Resistance: Very high, often exceeding 2000°F.

- Applications: Used for installing or repairing fire bricks and refractory panels. Learn more about fire-brick-adhesive.

-

Intumescent Fire-Stop Caulks:

- Description: A specialized sealant that expands when heated.

- Key Feature: Swells to form a dense barrier that blocks fire, smoke, and hot gases.

- Applications: Used to seal penetrations in fire-rated walls, such as where a chimney passes through a wall, to maintain the building’s fire rating.

Safety, Longevity, and Professional Expertise

Safety Precautions When Using Fireplace Caulk:

Always prioritize safety when working with chemical sealants:

- Ventilation: Work in a well-ventilated area to disperse fumes.

- PPE: Wear gloves and eye protection to prevent skin and eye contact.

- Read the Label: Always read the manufacturer’s instructions. For detailed safety information, consult the product’s Safety Data Sheet (SDS) (see what an SDS covers here).

- Proper Disposal: Dispose of empty tubes and waste according to local regulations.

How Long Does Fireplace Caulk Last?

A properly applied high-quality fireplace caulk can last 3 to 10 years. Inspect it annually before the heating season. Look for signs of failure like cracking, shrinking, or peeling. If you see smoke leaking from a sealed joint, the seal has failed and requires immediate attention.

When to Call a Professional

While minor caulking is a manageable DIY task, you should call a professional for:

- Extensive Damage: Large cracks may signal underlying structural problems that require fireplace-mortar-repair.

- Uncertainty: If you’re unsure which product to use or how to apply it correctly.

- Difficult Access: For hard-to-reach areas around the chimney or flue.

- Signs of Deeper Issues: Suspected flue liner damage or chimney leaks require an expert inspection.

If you lack the confidence to ensure a safe and lasting seal, it’s best to trust experienced masons. Our team brings over 30 years of experience to every project, ensuring high-quality results with owner oversight.

We are Gerrior Masonry & Landscape Construction Corp., based in Woburn, MA, and we proudly service Middlesex and Essex County, Massachusetts. For any masonry needs, from a new-fireplace-surround to complex chimney-repairs, our skilled team is here to help.