Fireplace Cement: Ultimate Guide 2025

What to Know Before You Buy

Fireplace cement is a high-temperature putty used to seal cracks and repair firebricks in fireplaces and wood stoves. Choosing the right product is essential for a safe, lasting repair.

Key Features to Consider:

- Temperature Rating: Look for products rated between 2000°F and 2700°F.

- Application Type: Available as a pre-mixed putty in cartridges or tubs.

- Curing Method: Formulations are either air-dry or require heat to cure fully.

Common Uses:

- Repairing cracked firebricks.

- Sealing mortar joints and flue pipes.

- Patching small holes in fireboxes.

Price Range:

Expect to pay between $5 to $65 per container, depending on the product’s size and quality.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years of experience, I know that using the correct fireplace cement is crucial for preventing more significant, costly repairs. My team has extensive experience with all types of high-temperature cements on the market.

Fireplace cement word guide:

A Homeowner’s Guide to Using Fireplace Cement

In my 34 years in the masonry business, I’ve learned that homeowners who understand their materials get longer-lasting results. Fireplace cement may seem simple, but knowing how to choose and use it properly is key for a successful, safe repair.

What Is Fireplace Cement and Why Is It Essential?

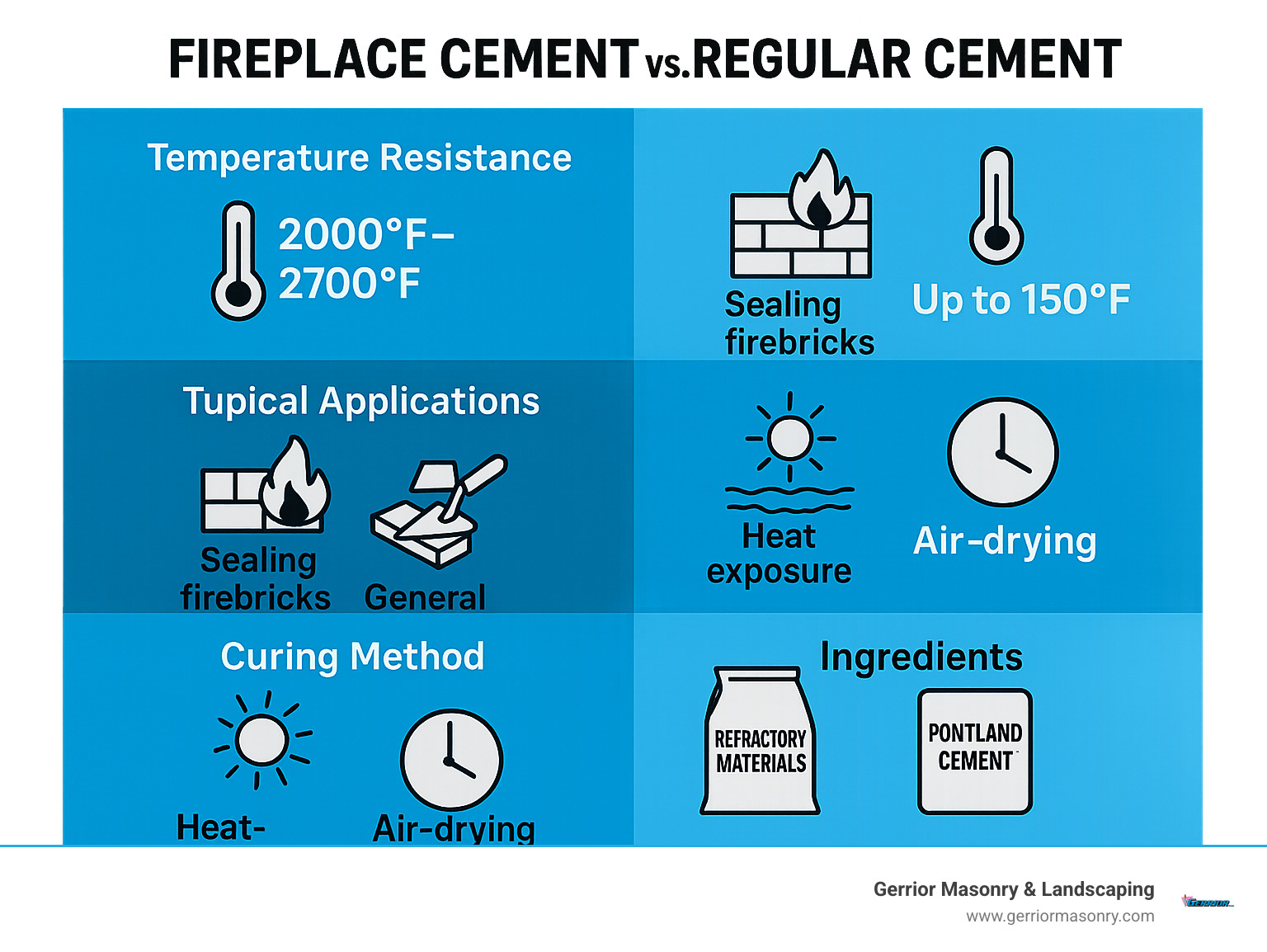

Fireplace cement is a specialized refractory sealant engineered to withstand the intense heat of a fireplace, where regular cement would fail. It remains durable at temperatures from 2000°F to 2700°F.

This high-temperature adhesive is essential for maintaining firebox integrity. Its main functions are sealing joints between firebricks, filling masonry cracks, and creating airtight connections for flue pipes and stove components.

A properly sealed firebox is crucial for both safety and efficiency. It prevents dangerous gases like carbon monoxide from leaking into your home and stops air leaks that disrupt proper draft and combustion.

Using the right fireplace cement for minor repairs can prevent major structural problems later. Addressing small cracks early with the correct material is a small investment that avoids expensive future rebuilds.

Key Properties and Types of Fireplace Cement

The heat resistance of fireplace cement comes from its unique ingredients, typically sodium silicate and specialized aggregates that handle extreme thermal cycling. Modern formulations are non-asbestos and safe to use.

While standard mortar fails at low temperatures, fireplace cement is rated for up to 2000°F, with premium versions withstanding 2700°F or more, making it ideal for hot-burning wood stoves and fireplaces.

Most fireplace cement is a pre-mixed putty, eliminating guesswork. It’s available in two main formats: cartridges for use with a caulk gun for precise sealing of small cracks and joints, and tubs for larger repairs applied with a trowel.

The curing process is typically two stages: an initial air-dry period of 12-24 hours, followed by a gradual heat-cure. This final heating, achieved by slowly bringing the fireplace up to temperature, transforms the cement into a durable, firebrick-like material.

| Feature | Cartridge Format | Tub Format |

|---|---|---|

| Best for | Precise sealing, joints under 1/8 inch | Larger cracks, patching, general repairs |

| Application tool | Caulk gun | Trowel or putty knife |

| Consistency | Smooth, caulk-like | Thicker, spreadable putty |

| Typical uses | Stove pipe connections, small gaps | Firebrick repair, mortar joint filling |

Common Applications and Uses

The versatility of fireplace cement makes it invaluable for maintaining heating appliances. Its most common applications include:

- Repairing firebricks: Constant heating and cooling can cause cracks or chips in firebricks. Fireplace cement patches these damages, restoring the protective barrier of the firebox.

- Filling mortar joints: When original mortar between firebricks deteriorates from heat, fireplace cement serves as a strong, heat-resistant replacement that withstands thermal stress.

- Sealing flue pipes: It creates an airtight, reliable seal when connecting stove pipes or sealing around flue liners, bonding effectively to metal, ceramic, and masonry to prevent gas leaks.

- Assembling wood stoves: The cement provides high-temperature bonding needed for installing cast iron stove components, range cookers, and furnace connections.

- Patching masonry: It can be used to patch masonry around the fireplace, especially where metal meets brick, to prevent air leaks that reduce efficiency and safety.

For issues beyond what fireplace cement can fix, consider professional chimney repairs services.

Step-by-Step Application Guide

Proper application is key to a lasting repair. Follow these steps for the best results.

- Surface Preparation: Ensure the surface is completely cool. Use a wire brush to remove all soot, dirt, and loose material. Vacuum away dust, then lightly dampen the area with water to improve adhesion.

- Cement Preparation: For tubs, stir the cement well, adding a teaspoon of water at a time if it’s too thick. For cartridges, simply snip the tip and load it into a caulk gun.

- Application: Push the fireplace cement firmly into cracks for a complete fill. For clean lines, use masking tape. For deep repairs, apply the cement in thin layers to prevent cracking as it cures.

- Drying and Curing: Let the repair air-dry for 12-24 hours. Do not expose it to heat during this time. Afterward, begin the heat-cure process by starting a small, low fire for two hours. Gradually increase the heat to medium-high for another four to six hours. This slow, controlled heating is crucial for preventing cracks and ensuring a durable bond.

Rushing any of these steps can lead to a failed repair, so take your time.

Safety, Maintenance, and Signs of Failure

Follow basic safety precautions when working with fireplace cement.

- Safety Gear: Ensure proper ventilation and wear safety goggles and heat-resistant gloves. The cement can irritate skin and eyes, so rinse with water upon contact. Keep it away from children and pets.

- Product Information: Review the product’s Safety Data Sheet (SDS) for specific warnings. Modern cements are asbestos-free and often low-VOC. You can review the Safety Data Sheet for high-temp cement to understand specific warnings.

To maintain your repair, conduct an annual inspection before the heating season. Look for these signs of failure:

- Crumbling or flaking cement.

- New cracks appearing in repaired areas.

- Smoke or gas leaks from sealed joints, which is a critical safety issue requiring immediate attention.

Proper maintenance includes gradual heating at the start of the season to reduce thermal shock. Consistent use can also extend the life of the repair by minimizing extreme temperature cycles.

Understanding Costs and Alternatives

The material cost for fireplace cement is a reasonable investment, with most DIY repairs costing between $10 to $50. Small cartridges run $5 to $20, while larger tubs are $15 to $40. Specialized castable refractory cements can cost $65 or more. These prices are for materials only and can be found at hardware stores, home centers, and online.

It is crucial to use the correct material, as alternatives can be dangerous. Regular silicones, standard mortars, epoxies, and grouts are not designed for high temperatures and will fail quickly in a firebox. They cannot withstand the heat and pose a safety risk.

True alternatives include refractory mortar, a dry-mix version of fireplace cement, and furnace cement, a similar product often used for metal heating appliances. Only use products specifically rated for high-temperature applications in your fireplace or stove to ensure a safe, durable repair.

When to Call a Professional for Fireplace Repair

While fireplace cement is excellent for many DIY repairs, some situations require a professional’s expertise. Recognizing your limits is key to ensuring your home’s safety.

Call a professional if you notice:

- Large or deep cracks: Cracks spanning multiple firebricks, deeper than a quarter-inch, or visibly growing often signal underlying structural issues. A simple patch won’t solve the root cause, such as a shifting firebox or water damage.

- Structural damage: Any signs of shifting bricks, bulging walls, or a leaning chimney are serious safety hazards. These require immediate attention from a qualified mason, as they cannot be fixed with fireplace cement.

- Water damage signs: White, chalky deposits (efflorescence), water stains, or soft, crumbly masonry indicate a moisture problem. The source of the water must be fixed before any repairs will last.

- Performance issues: Persistent smoke spillage or poor draft can point to complex problems like flue blockages or improper sizing that need professional diagnosis.

- Code compliance concerns: Major repairs affecting structural elements or flue systems must meet local building codes. A professional ensures your fireplace is repaired safely and legally.

If you’re facing any of these issues or are unsure about the extent of the damage, it’s best to seek a professional assessment. At Gerrior Masonry & Landscaping, we handle repairs ranging from simple mortar fixes to complete chimney rebuilds, ensuring every project meets the highest standards. Don’t hesitate to Contact us for professional fireplace mortar repair for peace of mind.

Gerrior Masonry & Landscape Construction is based in Woburn, MA, and services Middlesex and Essex County, Massachusetts.