Fireplace cement crack repair: 1 Essential Guide

Why a Cracked Fireplace Needs Your Attention

When you notice cracks in your fireplace, it’s a serious matter. Fireplace cement crack repair is crucial for your home’s safety. Ignoring these cracks can be dangerous. Flames can get through the fire-resistant layers. Burning embers can even blow into your walls. This creates a big fire risk. Also, carbon monoxide could escape into your home.

Here’s a quick overview of how to fix fireplace cement cracks:

- Clean the crack: Make sure the area is free of ash and loose debris.

- Apply the repair material: Use a high-heat refractory caulk or cement designed for fireplaces.

- Smooth the surface: Ensure the repair is even and fills the crack completely.

- Allow to dry and cure: Follow the product’s instructions for air drying and heat curing.

Cracks in your fireplace also weaken its structure. Over time, this can lead to bigger problems. Fixing them early keeps your fireplace safe and working well. It protects your home and family.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years in the business, my team and I have experience in ensuring the safety and longevity of masonry structures, including expert fireplace cement crack repair. We understand the importance of a properly maintained fireplace for your home’s value and your family’s peace of mind.

Fireplace cement crack repair vocab explained:

A Step-by-Step Guide to Fireplace Cement Crack Repair

Now that you understand why those cracks need attention, let’s roll up our sleeves and get to work. Don’t worry – fireplace cement crack repair isn’t rocket science, but it does require the right approach. Think of it like baking a cake: follow the recipe, use quality ingredients, and be patient with the process.

Choosing the Right Materials for the Job

Here’s where many DIY enthusiasts go wrong – they grab whatever’s handy at the hardware store. But your fireplace isn’t messing around when it comes to heat. We’re talking temperatures that can reach over 2000°F, so that regular caulk from your junk drawer just won’t cut it.

For those hairline cracks (less than 1/8 inch wide), a high-temperature refractory caulk is your best friend. These come in convenient tubes and work just like regular caulk, but they’re built tough. Look for products rated to handle at least 2000°F – some can even withstand temperatures up to 2550°F. That’s hot enough to melt copper!

For wider gaps or when you’re dealing with crumbling firebricks, you’ll need refractory mortar or cement. These usually come as dry mixes that you blend with water, or as ready-to-use pastes. The key difference? These products are specifically designed to expand and contract with your fireplace’s heating cycles without cracking.

Whatever you do, don’t use regular Portland cement. I’ve seen too many DIY repairs fail because someone thought cement was cement. Regular mortar will crack and fall out faster than you can say “fire hazard.” The specialized refractory materials contain ingredients that help them bond and flex with the intense heat cycles your fireplace experiences.

Before you start mixing anything, take a moment to read through the manufacturer’s safety data sheet. It might seem boring, but understanding how to handle these materials safely is crucial. Here’s a helpful resource: Understanding product safety data sheets.

Prepping the Crack for a Lasting Repair

You know how your mom always said “cleanliness is next to godliness”? Well, when it comes to fireplace cement crack repair, cleanliness is next to success. A dirty surface is like trying to put a bandage on muddy skin – it’s just not going to stick.

Start by cleaning out your firebox completely. Remove all the ash, soot, and any leftover wood pieces. If you’ve been putting off that annual cleaning, now’s the perfect time to tackle it. A clean fireplace isn’t just safer – it makes repairs much more effective.

Next, grab a wire brush and get to work on the crack itself. You want to scrub away any loose or crumbling material around the damaged area. This might seem aggressive, but you’re creating a solid foundation for your repair. Think of it as removing the weak spots so the new material has something strong to grip onto.

Once you’ve brushed everything loose, use a shop vacuum to suck up all that debris. Don’t skip this step – even tiny particles can prevent your repair material from bonding properly. For ceramic fireboxes, a gentle wash with soap and water followed by complete drying works wonders.

Here’s a pro tip: lightly dampen the crack area before applying your repair material. This helps the new cement bond better and prevents it from drying too quickly. Just moist, not soaking – we’re not trying to flood the thing.

Safety first, always. Make sure you’re wearing protective goggles, a dust mask, and gloves. Trust me, getting refractory dust in your eyes or lungs isn’t fun, and these materials can be tough on your skin.

The Proper Technique for Fireplace Cement Crack Repair

Now comes the satisfying part – actually fixing that crack. Take your time here because rushing this step is like hurrying through frosting a cake. You’ll just end up with a mess.

If you’re using refractory caulk in a tube, cut the nozzle tip at an angle to match your crack width. Load it into your caulking gun and apply steady, even pressure. The goal is to force the material deep into the crack, not just smear it on the surface. Think of it like filling a pothole – you want to pack it full.

For wider cracks or when using cement from a tub, a putty knife or small trowel becomes your tool of choice. Scoop up some material and really pack it into the crack. Don’t be gentle – push it all the way to the back of the void. If your crack is deeper than 1/8 inch, work in layers, letting each one air dry for 24 hours before adding the next.

Once the crack is filled, smooth the surface with your tool. A little trick I’ve learned over the years – dip your smoothing tool in water occasionally. This creates a clean, professional-looking finish that blends seamlessly with the surrounding masonry. Wipe away any excess with a damp cloth before it starts to set.

Getting the consistency right is crucial. If you’re mixing dry powder, aim for something between peanut butter and thick frosting. Too thin and it’ll run out; too thick and you won’t be able to work it into the crack properly.

Curing the Repair and Preventing Future Cracks

Here’s where patience becomes your best friend. Proper curing is what separates a lasting repair from one that’ll fail next winter. Most people want to light a roaring fire immediately, but that’s like putting a cake in a 500-degree oven – you’ll just ruin all your hard work.

Start with air drying for at least 24 hours. Some products specify a maximum air-dry time (usually 30 days), so check your manufacturer’s instructions. This initial period lets the material begin its chemical change.

The heat curing process is where the magic happens. Begin with a small, low-temperature fire (under 210°F). This gentle heat drives out any remaining moisture without shocking the repair. Keep this gentle fire going until the repair looks completely dry.

Next comes the final cure with a hotter fire (around 500°F) for 1-2 hours. This higher temperature activates the chemical bonds that make your repair as strong as the original firebrick. It’s like tempering steel – the heat treatment gives it strength.

To prevent future cracks, think prevention, not just repair. Annual inspections are your first line of defense. Keep your fireplace clean of ash and soot buildup, which can be corrosive over time. Avoid building oversized fires that stress your masonry beyond its limits.

Water damage is often the hidden culprit behind fireplace cracks. Make sure your chimney cap and flashing are in good shape. Even small leaks can cause big problems when water freezes and expands in tiny cracks.

For comprehensive information about maintaining your entire chimney system, check out More info about professional chimney repairs.

DIY vs. Professional Repair: Making the Right Call

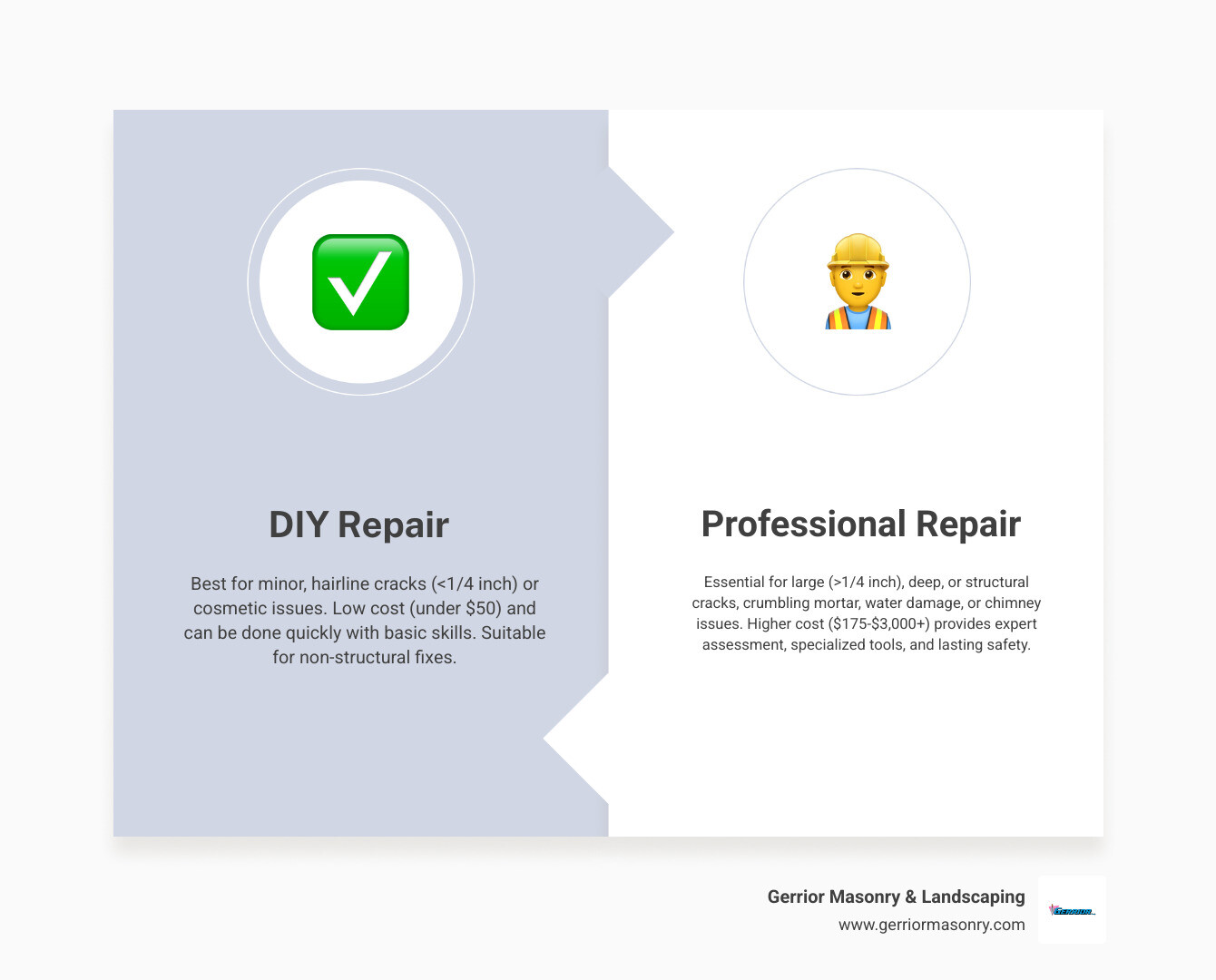

When you’re staring at a crack in your fireplace, the big question isn’t just “Can I fix this?” but “Should I fix this myself?” It’s a fair question, and honestly, the answer depends on what you’re dealing with. While a DIY fix works great for minor issues, significant damage needs a professional touch to keep your family safe and your home sound.

Think of it this way: patching a small hairline crack is like putting a band-aid on a paper cut. But trying to DIY a major structural crack? That’s like performing surgery with a butter knife. Not a great idea.

Understanding the Costs: DIY vs. Hiring a Pro

Let’s talk money, because we know that’s often the first thing on your mind when you spot a crack. The good news? For small, hairline cracks, fireplace cement crack repair doesn’t have to break the bank.

A tube of high-temperature refractory caulk runs about $15. Throw in a caulking gun, putty knife, and some basic cleaning supplies, and you’re looking at under $50 total. That’s pretty appealing when you’re dealing with minor cosmetic issues or small, non-structural cracks.

But here’s where things get interesting. Professional repairs? Well, that’s a whole different ballgame. You’re looking at anywhere from $175 to $3,000 or more, depending on what’s actually wrong. That wide range covers everything from simple mortar joint repairs to complete firebox rebuilds.

Please note: the professional repair cost range mentioned here is an average based on national internet data and is not a quote from Gerrior Masonry & Landscaping. Costs can vary significantly based on the extent of the damage, regional pricing, and the specific services required.

The cost difference really comes down to what you’re fixing and how complex the job is. A simple crack might take you an hour and cost $15. But if that crack is actually a symptom of a bigger structural problem, you could be looking at days of professional work.

The time factor is worth considering too. A DIY repair might seem quick, but if you factor in research time, multiple trips to the hardware store, and potential do-overs, it adds up. Professionals come prepared and get it right the first time.

When to Leave Fireplace Cement Crack Repair to the Experts

Here’s where we get serious about safety. While we love a good DIY project, some situations absolutely require professional expertise. Knowing when to step back isn’t admitting defeat – it’s being smart about protecting your home and family.

Large or deep cracks are our first red flag. If you’re looking at a crack wider than about 1/4 inch, or one that seems to go way back into the masonry, you’re dealing with a structural issue. This isn’t a patch job – it needs proper assessment and a robust repair solution.

Crumbling bricks or mortar around the crack tell a different story entirely. When masonry starts turning to powder or easily crumbles in your hand, you’re not just looking at a crack anymore. You’re seeing widespread material failure that needs professional attention.

Water damage signs are another major concern. If you notice bricks flaking (we call this spalling), white powdery residue, or persistent dampness around your fireplace or chimney, water is getting where it shouldn’t. Simply patching cracks won’t solve the root problem – you need to find and fix the leak.

Structural concerns are the most serious issue. Cracks extending from the fireplace into surrounding walls, or a fireplace that seems to be leaning or shifting, indicate foundation problems or chimney settlement. These can lead to catastrophic failure if ignored.

And honestly? If you’re lacking experience or confidence with any step of the process, that’s perfectly valid reason to call in the pros. An improper DIY repair can create a false sense of security and potentially make things worse.

Here’s something important: your average handyman typically isn’t equipped to handle complex fireplace cement crack repair. You need someone who specializes in refractory materials and fireplace construction. Our team has over 30 years of experience in masonry work, and we can tell you whether a firebox is worth saving or needs a complete rebuild.

For expert assessment and lasting repairs, trust a certified professional. Gerrior Masonry & Landscaping provides expert fireplace mortar repair services. Our team is based in Woburn, MA, and proudly serves the communities of Middlesex and Essex County, Massachusetts, including towns like Acton, Andover, Arlington, Bedford, Burlington, Chelmsford, Concord, Danvers, Lexington, Lowell, Lynnfield, Malden, Medford, Melrose, Newton, North Andover, Peabody, Reading, Salem, Stoneham, Sudbury, Tewksbury, Wakefield, Waltham, Watertown, Wayland, Westford, Wilmington, and Winchester.