Historic masonry repair: 2025 Ultimate Care

The Art and Science of Preservation

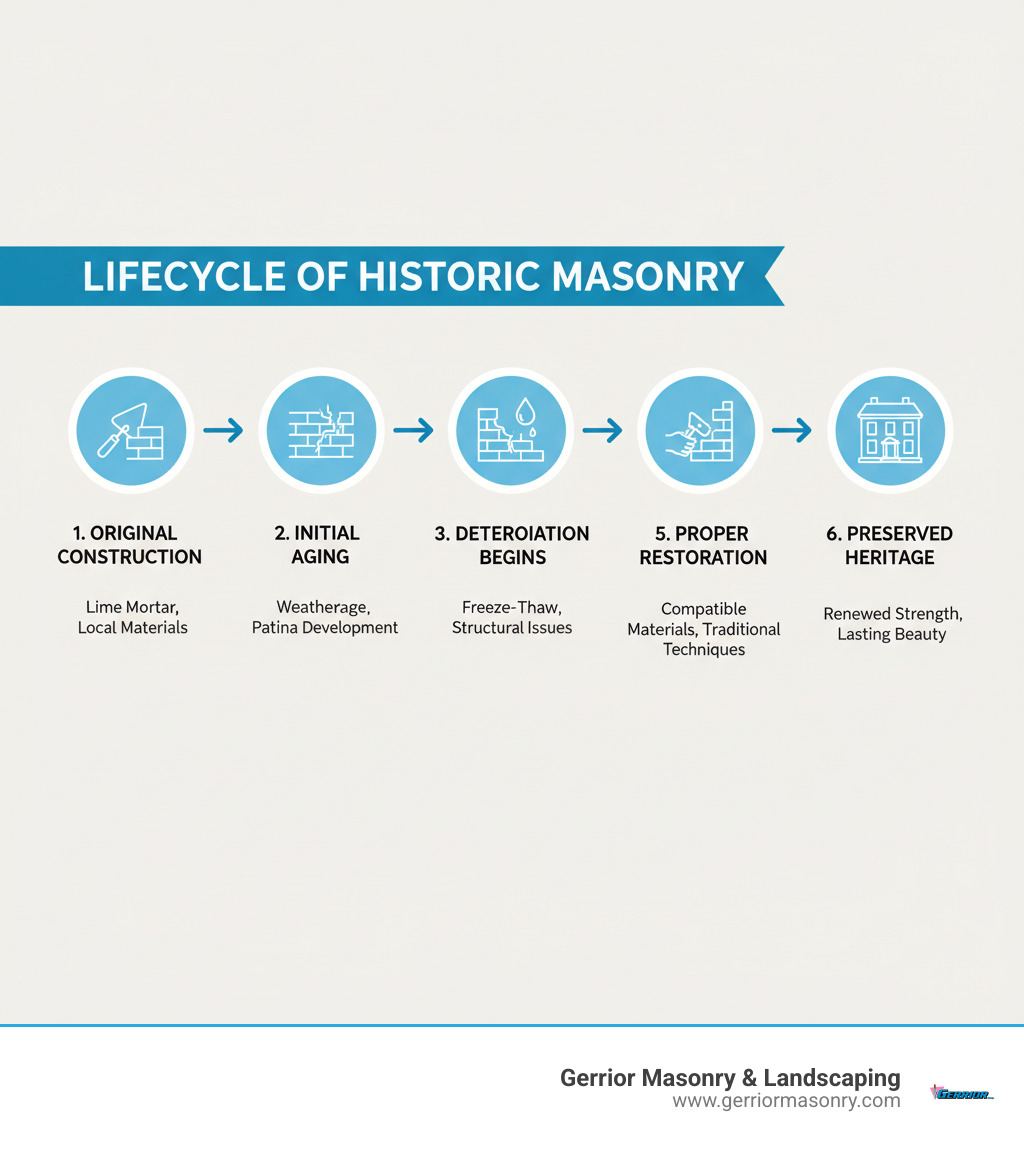

Historic masonry repair requires understanding traditional materials, assessment techniques, and compatible restoration methods to preserve the structural integrity and historical character of older buildings. Here’s what you need to know:

Essential Steps for Historic Masonry Repair:

- Assess the damage – Identify water infiltration, mortar deterioration, and structural issues

- Prioritize repairs – Start with horizontal surfaces (parapets, sills, roofs) to stop water entry

- Use compatible materials – Lime-based mortars that are softer and more permeable than original masonry

- Employ gentle cleaning – Avoid sandblasting or harsh chemicals that can damage historic surfaces

- Hire qualified professionals – Specialized knowledge is crucial for preservation work

As Winston Churchill once observed, “We shape our buildings, and afterwards our buildings shape us.” This wisdom is especially true for our historic masonry structures—buildings that have shaped communities for centuries.

Historic buildings, generally those 50 years or older with architectural significance, face unique challenges. They were built with lime-based mortars and mass wall systems designed to manage water through absorption and evaporation, not modern barrier methods.

Water infiltration is the primary enemy of historic masonry, causing everything from freeze-thaw damage to structural failure. The key to successful preservation is understanding that original lime mortars were intentionally softer and more porous than the brick or stone. This allowed the wall system to breathe. When modern Portland cement mortars are used for repairs, they trap moisture and cause the original masonry to deteriorate faster.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. With over 34 years serving Massachusetts, we’ve seen how proper historic masonry repair techniques can breathe new life into aging structures, combining respect for tradition with modern diagnostics.

Historic masonry repair further reading:

Understanding and Assessing Historic Masonry

When we examine a historic building, we’re looking at an engineered system that has weathered New England storms for centuries. Understanding how these systems work is essential for effective historic masonry repair.

The Evolution of Masonry Walls and Water Management

Historic masonry materials are fundamentally different from those used today. Old buildings weren’t designed to keep water out completely; they were designed to let moisture move through the wall system naturally. For centuries, builders used lime-based mortars that were intentionally softer and more porous than the bricks or stones. This allowed walls to “breathe,” absorbing moisture and releasing it as conditions dried. The arrival of Portland cement in the late 1800s introduced a barrier approach, which causes problems when mixed with historic, breathing wall systems.

Here are the four main types of historic masonry wall systems we encounter in Massachusetts:

- Mass Masonry Walls: The oldest approach, these are thick, solid walls of brick or stone. They manage water through absorption and evaporation, acting like a natural sponge that dries itself out.

- Transitional Masonry: Emerging between the 1890s and WWII, these buildings combine traditional masonry exteriors with early steel and concrete frames. They often lack proper movement joints, creating stress between different materials.

- Curtain or Barrier Walls: Here, masonry is used as an exterior cladding, with the structure doing the heavy lifting. The design assumed the masonry was a complete water barrier, but water always finds a way in, causing issues if internal drainage wasn’t planned.

- Cavity Walls: A smarter system that acknowledges water will penetrate the exterior. An air space between the outer masonry and inner wall allows water to drain down to flashings and weep holes, protecting the interior.

Common Causes of Deterioration in Historic Masonry

Water infiltration is the villain in almost every masonry story. Here are the most common ways it and other factors cause damage:

- Freeze-Thaw Damage: When water inside masonry freezes, it expands by about 9%. This repeated cycle of expansion exerts immense pressure, eventually causing the brick or stone to crack and spall.

- Corrosion of Embedded Metals: Water corrodes embedded iron lintels, anchors, and ties. As the metal rusts, it expands—a process called “rust jacking”—which acts like a slow-motion explosive, cracking and displacing the surrounding masonry.

- Material Incompatibility: This is often the result of well-intentioned but misguided repairs. Using modern, hard Portland cement mortar to repoint a historic wall traps moisture inside the softer, more porous historic bricks. When that moisture freezes, it destroys the original masonry unit from within.

- Mortar Joint Failure: Mortar joints make up 20-25% of a masonry wall and are the first line of defense. When they deteriorate from age or weathering, they become direct pathways for water entry.

- Structural Issues & Deferred Maintenance: Foundation settlement or thermal expansion problems can cause significant damage. However, the most preventable cause is often deferred maintenance. Small, unaddressed issues like a few cracked mortar joints can become major, expensive problems. Chimneys are particularly vulnerable, which is why we specialize in chimney masonry repair.

The Critical Steps of a Condition Assessment

Before any repair, a thorough condition assessment is mandatory. The principle is simple: diagnosis before treatment. We identify root causes, not just patch symptoms.

Our assessment process starts with background research, reviewing original drawings and past repair records from sources like the APT Heritage Library. The investigation and testing phase is hands-on. We conduct a thorough visual inspection, use “sounding” (tapping surfaces) to find hidden defects, and perform material analysis on small samples to ensure repair materials are compatible. When needed, non-destructive evaluation (NDE) techniques like infrared thermography let us see internal conditions without causing damage.

We follow professional standards, such as those in Preservation Briefs 35: Understanding Old Buildings: The Process of Architectural Investigation, to ensure accuracy. Finally, we prioritize repairs, addressing immediate safety hazards first, then focusing on stopping water infiltration. Our masonry restoration services are designed to implement these plans effectively.

The Complete Guide to Historic Masonry Repair and Preservation

Think of historic masonry repair like caring for a vintage car—you need the right parts and techniques, and you must understand how the system works. Successful preservation means fixing what’s broken by understanding why it broke in the first place.

A Prioritized Approach to Historic Masonry Repair

We follow a repair hierarchy that tackles problems in order of importance. After addressing immediate safety hazards, we always start from the top down.

- Horizontal Surfaces: We focus first on roofs, parapets, and window sills. Fixing these stops water infiltration at its source.

- Flashing Systems: Properly installed sheet metal flashings are crucial for long-term water management, with some systems lasting up to 100 years.

- Joint Repair: Repointing with compatible mortar is a core task. Since mortar joints make up 20-25% of a wall, they are the first line of defense against water. The National Park Service guide on Repointing Mortar Joints in Historic Masonry Buildings is an essential resource.

- Masonry Unit Repair: We either patch original units with compatible materials or, if damage is severe, replace them while preserving as much original character as possible.

- Sealants: These are used sparingly on historic masonry, typically for control joints, and require replacement about every 10 years.

Our team handles all these techniques with care, as detailed in our Brick and Masonry Repair services.

Choosing Compatible Materials for Historic Masonry Repair

The golden rule of restoration is that new materials must be compatible with the old. Using the wrong material is where many repairs go wrong.

Mortar matching is a science. The new mortar must always be softer and more porous than the historic masonry unit. This is the non-negotiable “softer than” rule. It ensures that stress from movement and moisture is absorbed by the replaceable mortar joint, not the irreplaceable historic brick or stone.

Vapor permeability is equally critical. Historic walls need to breathe. Lime-based mortars allow moisture to pass through, while modern Portland cement mortars trap it. In Massachusetts winters, that trapped moisture freezes and destroys masonry from the inside out. When selecting replacement units, we match not just color but also physical properties like compressive strength and water absorption to ensure the entire system works harmoniously. Our expertise in Stone Masonry Repairs ensures we select the right materials every time.

| Feature | Historic Lime Mortar | Modern Portland Cement Mortar |

|---|---|---|

| Compressive Strength | Low; softer than masonry units | High; harder than most historic masonry units |

| Permeability | High; allows vapor and moisture to pass through | Low; tends to trap moisture |

| Flexibility | High; accommodates building movement | Low; rigid, can cause cracking in adjacent masonry |

| Longevity | Durable and sacrificial to protect masonry | Can cause premature failure of historic masonry units |

Long-Term Preservation: Cleaning, Insulation, and Professional Expertise

Long-term preservation extends beyond immediate fixes to include ongoing care.

Gentle cleaning follows the “gentlest means possible” principle. We start with low-pressure water and natural bristle brushes, following guidance from Preservation Briefs 1: Assessing Cleaning and Water-Repellent Treatments for Historic Masonry Buildings. Methods to avoid include sandblasting, high-pressure washing, and harsh chemicals, which cause irreversible damage.

Interior insulation is risky for historic masonry. It can trap moisture within the wall, leading to freeze-thaw damage. Before insulating, a hygrothermal analysis is essential to understand how the wall will perform, as detailed in resources like the Building Science Corporation’s BSD-114: Interior Insulation Retrofits of Load-Bearing Masonry Walls in Cold Climates.

The value of craftsmanship cannot be overstated. Historic masonry repair demands specialized training and experience. At Gerrior Masonry & Landscaping, our over 30 years of experience and commitment to owner oversight ensures every project receives the attention it deserves. When working with irreplaceable historic materials, there’s no room for shortcuts.

Gerrior Masonry & Landscape Construction is based in Woburn, MA, and proudly services Middlesex and Essex County, Massachusetts.