Perforated Drain Pipe Retaining Wall: 7 Powerful Reasons 2025

Why Perforated Drain Pipe Retaining Wall Systems Prevent Costly Failures

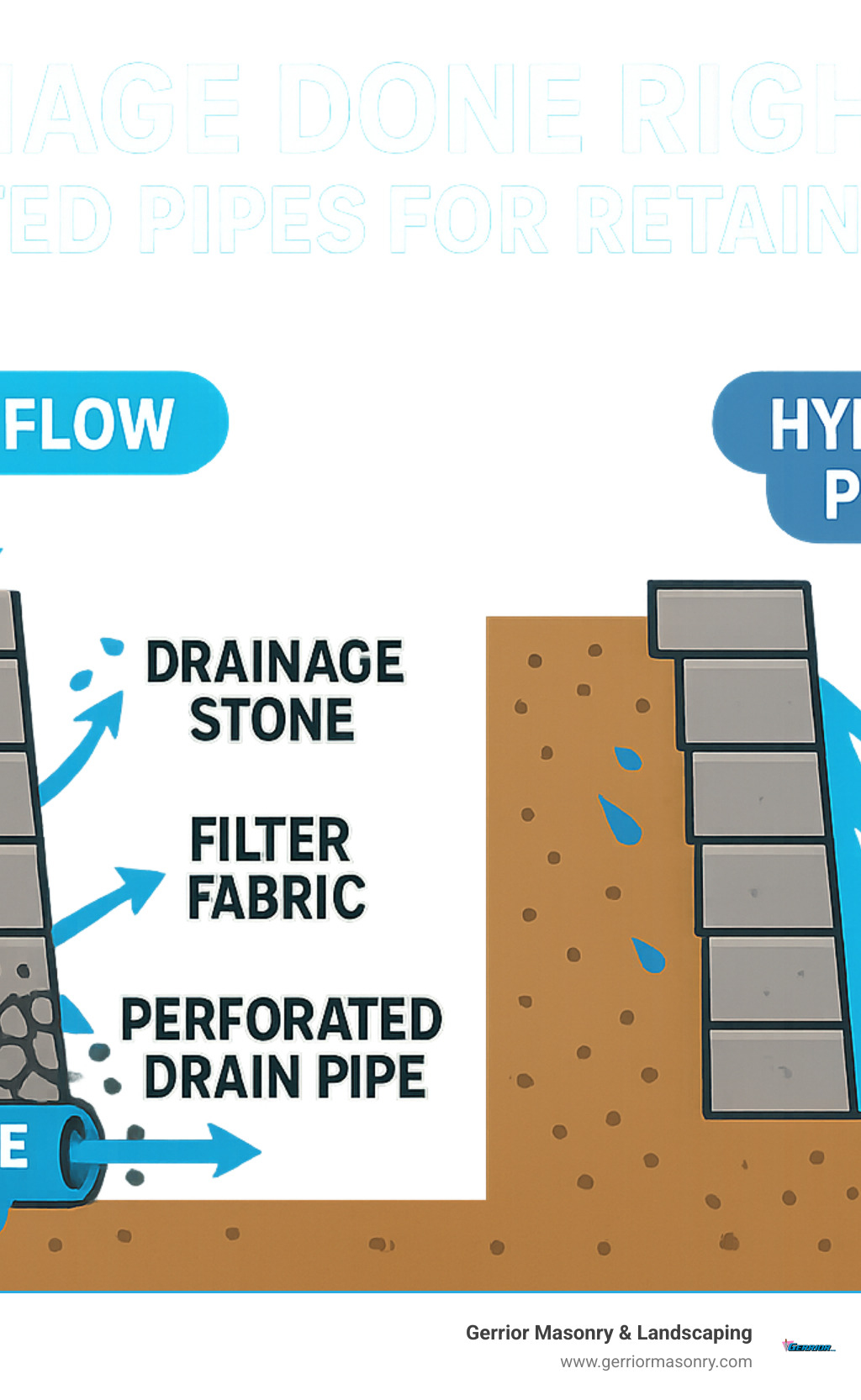

A perforated drain pipe retaining wall system is essential for managing water pressure behind retaining walls to prevent structural failure. Here’s what you need to know:

Key Components:

– Perforated pipe (4-inch diameter) placed at wall base with 1% slope

– Drainage stone (angular #57 aggregate) extending 12+ inches behind wall

– Filter fabric to prevent soil clogging

– Outlets spaced every 30-50 feet for water discharge

When Required:

– Walls 4+ feet tall

– Clay or poorly-draining soils

– Concrete or block construction

– Slopes directing water toward wall

– Areas with groundwater or tiered walls

Pipe Orientation: Holes should face down to allow water entry from below and prevent pipe floating.

Water is the major cause of retaining wall failures. Without proper drainage, hydrostatic pressure builds up behind walls, creating enough force to push them over or cause catastrophic blow-outs. Even a small amount of trapped water can turn stable soil into a heavy, unstable mass that threatens your wall’s integrity.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction, and I’ve been installing perforated drain pipe retaining wall systems for over 34 years throughout Massachusetts. Proper drainage design has saved countless walls from premature failure and prevented expensive rebuilds for my clients.

Why Every Retaining Wall Needs a Drainage Plan

Picture water building up behind your retaining wall like a battering ram that never gets tired. That’s exactly what hydrostatic pressure does—it creates a relentless horizontal force that pushes against your wall 24/7. The more water that accumulates, the stronger this force becomes.

Here in Massachusetts, we see this problem amplified by our clay soils. When these soils get saturated, they don’t just hold water—they actually lose their strength and create even more lateral load against your wall. It’s like the soil transforms from a supportive friend into a heavy, unstable enemy.

Our freeze-thaw cycles make things even worse. Water seeps into every tiny crack and crevice, then expands when it freezes, creating additional pressure that can literally tear walls apart from the inside out.

After three decades of installing perforated drain pipe retaining wall systems, I can tell you that improper drainage causes more wall failures than any other factor. We’ve seen perfectly solid-looking walls completely blow out after a single heavy rainstorm simply because the water had nowhere to go.

When groundwater accumulates without proper management, even the best-built wall becomes vulnerable. That’s why understanding proper drainage principles is crucial for any retaining wall project.

For more comprehensive information about managing water in your landscape, check out our guide on the importance of proper drainage in hardscaping and masonry projects.

Risks of Skipping Drainage

We’ve seen the heartbreaking aftermath of skipped drainage more times than I’d like to count. The damage isn’t just expensive—it can be dangerous.

Wall bulging and leaning are usually the first warning signs. The wall starts tilting forward or developing an obvious bow as hydrostatic pressure gradually wins the battle. Most homeowners notice this happening slowly over months or even years.

But sometimes there’s no warning at all. Catastrophic blow-outs happen when water pressure builds up to a breaking point. We’ve witnessed stone walls literally explode outward during heavy rains, sending rocks flying and creating serious safety hazards.

Soil erosion becomes inevitable when water finds its own escape route. Instead of following a planned drainage system, water carves unpredictable paths that wash away soil from around and under your wall foundation, creating dangerous voids.

Perhaps most frustrating for homeowners is finding that skipping drainage voids warranties. Most wall manufacturers and contractors consider proper drainage a fundamental requirement, not an optional upgrade. Without it, you’re on your own if problems develop.

When Drainage Is Mandatory

Based on industry standards and our decades of experience, certain situations make drainage systems absolutely non-negotiable.

Any wall 4 feet or taller requires proper drainage—no exceptions. The higher the wall, the greater the potential for catastrophic failure and serious injury.

Clay soils and other poorly-draining soil types make drainage mandatory regardless of wall height. These soils retain water like a sponge and lose their supporting strength when saturated.

Concrete block walls and other solid wall systems can’t allow water to weep through naturally like dry-stacked stone walls can. They need engineered drainage to handle water pressure safely.

If your wall sits where slopes direct water toward it, you’re essentially building at the bottom of a funnel. All that runoff has to go somewhere, and without proper drainage, it goes straight into your wall.

Areas with groundwater or buried water sources within 50 feet create constant pressure that never lets up. Underground springs, buried streams, or even old septic systems can create ongoing drainage challenges.

Tiered walls present special challenges because water can accumulate between levels, creating multiple pressure points that require careful management throughout the entire system.

Core Components of a Retaining Wall Drainage System

Think of a perforated drain pipe retaining wall system like a well-orchestrated team—every player has a specific role, and they all need to work together to win the game. When we design these systems at Gerrior Masonry, we make sure each component is properly sized and positioned to handle whatever Mother Nature throws at it.

The heart of any effective drainage system starts with drainage stone—this creates your water highway behind the wall. Next comes non-woven geotextile fabric, which acts like a coffee filter, letting water through while keeping soil particles out. The perforated drainage pipe serves as your main collection and transport system, gathering water and moving it away from the wall.

You’ll also need outlets and weep holes to give that collected water somewhere to go—think of these as the exit ramps on your water highway. Many contractors add a soil sock or filter wrap around the pipe for extra protection against clogging. Finally, clean backfill material behind the stone zone completes the system by providing proper drainage without compromising stability.

For larger drainage challenges beyond retaining walls, we often integrate these systems with our dry well drainage solutions to handle excess water runoff.

Drainage Stone & Geotextile

Here’s where many contractors cut corners, and it comes back to bite them later. We always use angular #57 stone because those sharp edges lock together like puzzle pieces while creating the void spaces water needs to flow freely. The stone size ranges from 3/4 inch down to 1/4 inch—small enough to work around the pipe but large enough to maintain good drainage.

Why shape matters so much: Round stones like pea gravel might look similar, but they roll around like marbles and don’t create stable drainage channels. We’ve seen too many failed systems where contractors used the wrong aggregate to save a few dollars.

The stone needs to be clean—really clean. We specify less than 10% fines content, which means very little dust or small particles that could clog up the works. It’s like the difference between a clean gravel driveway and one that turns to mud when it rains.

Placement is everything when it comes to drainage stone. We install at least 12 inches behind the wall, but often go with 24 inches in clay soils or areas where groundwater is an issue. The stone should extend up to within 6 inches of the top of the wall—any higher and you risk it showing through the wall face.

Geotextile fabric installation requires attention to detail that separates professional installations from weekend warrior attempts. We use non-woven filter fabric that’s 3 feet wide, overlapping seams by 6 inches and extending 6 inches up the wall face. The fabric needs to completely wrap the stone zone while allowing water to pass through freely. Never use woven fabric—it clogs faster than a teenager’s bedroom floor collects clothes.

Outlets & Weep Holes

Collecting water is only half the job—you need to get it out of there, and that’s where outlet spacing and design become critical. We space outlets every 30 to 50 feet along the wall, with closer spacing in problem soils like clay where water doesn’t move as freely.

Through-wall outlets work great for shorter walls where you don’t mind seeing the pipe exit. We cut clean openings through the wall face and extend the pipe beyond the wall structure. It’s functional but not always the prettiest solution.

Under-wall outlets give you a cleaner look by routing the drainage pipe underneath the wall foundation to daylight at the ends or low points. This takes more planning during construction, but the finished appearance is worth it for visible walls.

When we want the best of both worlds—function and appearance—we install Universal Wall Drains. These architectural-grade components hide the drainage pipes while providing excellent water flow. They come in different sizes and colors to match various block types, so they blend right into the wall face.

Don’t forget about rodent protection—we always install screens or grates over outlets. You’d be amazed how quickly a family of chipmunks can turn your carefully designed drainage system into their winter condo, completely blocking water flow when you need it most.

Choosing the Right Perforated Drain Pipe Retaining Wall

Selecting the right perforated drain pipe retaining wall system isn’t as simple as grabbing whatever’s available at the hardware store. After three decades of installing drainage systems, I’ve learned that the wrong pipe choice can turn a solid retaining wall into a future headache.

Material matters more than you might think. We always recommend PVC or HDPE pipes because they won’t rust, corrode, or break down from soil chemicals. I’ve dug up metal pipes that looked like Swiss cheese after just a few years in our acidic New England soil. Plastic pipes, on the other hand, can last for decades without losing their structural integrity.

Standard sizing keeps things simple. A 4-inch diameter pipe handles the drainage needs of most residential retaining walls while being easy to work with during installation. Smaller pipes clog more easily, and larger ones are usually overkill for typical applications.

When shopping for pipes, look for products that meet ASTM F810 standards. This certification ensures the pipe will maintain its shape under soil pressure and that the perforations won’t close up over time.

| Pipe Type | Pros | Cons | Best Use |

|---|---|---|---|

| All-Around Perforated | Maximum drainage efficiency, reduced clog risk | Higher cost | Clay soils, high water table |

| Two-Slot (Holes on sides) | Lower cost, adequate for most applications | More prone to clogging | Well-draining soils |

| Corrugated with Sock | Built-in filtration, flexible installation | Sock may clog in fine soils | Variable soil conditions |

The choice between all-around perforated and two-slot pipes depends on your specific conditions. In Massachusetts clay soils, I typically recommend all-around perforations because they provide multiple water entry points and reduce the chance of complete blockage.

For detailed technical specifications and the latest research on pipe efficiency, manufacturers provide comprehensive guides through retailers like Home Depot.

Should Perforated Drain Pipe Retaining Wall Holes Face Up, Down, or All Around?

This question sparks heated debates at contractor meetings, but the physics don’t lie. Holes should face down, not up, despite what seems logical at first glance.

Here’s why holes down works better: Water naturally flows to the lowest point behind your wall. When holes face downward, that water gets forced up into the pipe and immediately carried away to the outlet. It’s active drainage from exactly where water wants to collect.

Holes facing up create problems because they only work after water rises above the pipe level. Until then, water sits below the pipe, building up hydrostatic pressure against your wall. That’s exactly what we’re trying to prevent.

Buoyancy becomes a real issue with upward-facing holes. Pipes are lighter than water, so they want to float when surrounded by saturated soil. This can shift your carefully placed drainage system out of position. Downward-facing holes help anchor the pipe where it belongs.

All-around perforations offer the best performance by allowing water entry from multiple directions. They’re particularly effective in clay soils where water movement patterns can be unpredictable. While they cost more upfront, they provide insurance against partial blockages that could compromise your drainage system.

How to Size a Perforated Drain Pipe Retaining Wall

Proper sizing ensures your perforated drain pipe retaining wall system can handle Massachusetts weather at its worst. I’ve seen undersized systems fail during those spring storms that dump three inches of rain in two hours.

Flow rate calculations start with understanding your local rainfall patterns. In our area, we design systems to handle storm events that can overwhelm inadequate drainage in minutes. The pipe needs to carry away water faster than it’s entering the system.

Wall dimensions directly impact sizing needs. Longer walls collect more water, and taller walls create larger drainage areas behind them. For walls over 100 feet long, we typically install multiple outlet points rather than trying to push all that water through a single pipe run.

Slope requirements can’t be ignored. Maintain at least 1% slope (one-eighth inch per foot) to keep water moving toward outlets. For longer runs, we increase this to 2% slope to maintain flow velocity and prevent sediment from settling in the pipe.

Redundancy planning means designing with backup capacity built in. If one section becomes partially blocked by roots or sediment, the system should still function effectively. This is why we space outlets closer together than minimum code requirements and why proper maintenance matters so much.

Installation Best Practices

Getting your perforated drain pipe retaining wall system installed correctly makes the difference between a drainage system that works for decades and one that fails within a few years. After 34 years of installing these systems throughout Massachusetts, I’ve learned that the details matter more than you might think.

The foundation of any successful drainage installation starts with proper trench preparation. We excavate to the right depth—typically 6 to 12 inches below the wall base—making sure the trench is wide enough to accommodate the pipe plus 6 inches of drainage stone on all sides. This isn’t a place to cut corners.

Creating a firm, compacted base comes next. We use 2 to 3 inches of compacted drainage stone to create a level foundation. This prevents the pipe from settling or shifting over time, which can disrupt the entire system’s flow patterns.

Pipe bedding requires careful attention to detail. The perforated pipe must be completely surrounded by clean drainage stone, ensuring contact on all sides. We’ve seen too many installations where stone doesn’t fully support the pipe, creating what we call “bridging” that can lead to pipe damage or poor drainage performance.

The fall requirements are non-negotiable—maintain a consistent 1 to 2 percent slope toward outlets throughout the entire installation. We use string lines or laser levels to ensure proper slope, because even small variations can create low spots where water pools instead of flowing to the outlets.

For walls built on challenging terrain, our comprehensive guide on how to build a retaining wall on a slope provides additional installation considerations.

Step-by-Step Placement

The installation sequence matters just as much as the individual components. We start by excavating the drainage zone behind the wall to accommodate 12 or more inches of stone backfill plus the pipe trench. This gives us the working room we need for proper installation.

Next, we lay the filter fabric on the excavated soil surface, extending it up the back of the wall. The non-woven geotextile fabric gets overlapped by at least 6 inches at seams—no exceptions. This fabric barrier prevents soil from migrating into the drainage stone over time.

Adding the base stone comes next. We place and compact 2 to 3 inches of drainage stone to create that level bed for the pipe. This step sets up everything that follows, so we take time to get it right.

Setting the pipe requires precision. We position the perforated pipe on the stone bed, ensuring proper slope toward outlets throughout the entire run. Stakes or temporary supports keep everything in position during backfilling—learned this lesson the hard way years ago when a pipe shifted during installation.

Testing the slope happens before we cover anything up. We verify fall using string lines or levels, then pour water in the high end to confirm it flows toward the outlet. If water pools anywhere, we adjust before proceeding.

Finally, we connect the outlets, ensuring watertight joints and proper support at wall penetrations. These connections take the most abuse over time, so we use quality fittings and take extra care with the installation.

Backfilling & Compaction Tips

The backfilling process can make or break your drainage system. We maintain at least 12 inches of clean drainage stone around and above the pipe. This creates the free-draining zone that prevents water buildup behind your wall.

Compaction equipment selection depends on the area we’re working in. We use plate compactors for stone areas and hand tampers near the wall face. Heavy equipment stays away from areas where it could damage the wall or crush the drainage pipe.

Lift thickness follows strict guidelines—we compact backfill in 2-inch lifts for hand tamping or 6-inch lifts with mechanical compactors. This ensures proper density without creating voids that could cause settling later.

We’re particularly careful about wall face protection, preventing bridging where backfill material spans across to the wall face without proper support underneath. This bridging can create pressure points that damage the wall over time.

Soil separation remains critical throughout the process. We keep native soil completely separate from drainage stone using filter fabric barriers. Never mix soil into the drainage zone—it reduces permeability and eventually clogs the system, turning your investment into an expensive problem.

Maintenance, Common Mistakes & Troubleshooting

Even the best-installed perforated drain pipe retaining wall systems need some love and attention to keep working properly. Think of it like your car—regular maintenance prevents big problems down the road.

Over our 30+ years in business, we’ve learned that a little preventive care goes a long way toward avoiding expensive repairs. The good news is that maintaining your drainage system isn’t complicated or time-consuming.

Watch for warning signs that your drainage system needs attention. Water staining on your wall face is often the first clue that something’s not right. Standing water behind the wall after a rainstorm should never happen with a properly functioning system.

Annual visual inspections are your best defense against problems. Walk along your wall and check each outlet for blockages, vegetation growth, or unwelcome animal residents. We’ve pulled everything from tennis balls to bird nests out of drainage outlets over the years.

Flush testing every 3-5 years helps identify problems before they become disasters. Simply pour water into the high end of your drainage system and watch it flow out the outlets. If water doesn’t flow freely, it’s time for professional cleaning.

Vegetation control is crucial in our Massachusetts climate. Plants love the moist conditions around drainage areas, but their roots can seriously damage your system. Keep shrubs and trees at least 6 feet away from drainage zones.

Here in Massachusetts, frost heave can wreak havoc on poorly protected drainage systems. Pipes installed too shallow or without proper insulation can crack when water freezes and expands inside them.

Top Mistakes to Avoid

After three decades of fixing other people’s drainage disasters, I’ve seen the same mistakes over and over again. The frustrating part is that most of these problems are completely preventable.

No slope or reverse slope is the number one killer of drainage systems. Water won’t flow uphill, no matter how much you wish it would. Even a slight reverse slope will cause water to pond in your pipe instead of flowing to the outlet.

Using pea gravel instead of angular stone might save a few dollars upfront, but it’s false economy. Pea gravel doesn’t create the void spaces needed for proper drainage, and it shifts around over time. We’ve seen entire drainage zones turn into solid masses when round stone gets compacted.

Installing holes facing up seems logical but works against you. Water has to rise above the pipe level before it can enter, which means hydrostatic pressure is already building against your wall. Plus, pipes with holes on top tend to float when water levels rise.

Skipping filter fabric to save money is like building a house without a foundation. Soil particles will migrate into your drainage stone and eventually clog everything. We’ve excavated systems that looked like concrete because fine soil had filled all the void spaces.

Spacing outlets too far apart creates weak points in your system. Heavy rains can overwhelm localized areas before water can travel to distant outlets. We’ve seen walls fail between properly functioning outlets simply because they were spaced too far apart.

Crushing or kinking pipes during installation happens more often than you’d think. Heavy equipment or careless backfilling can damage pipes, reducing flow capacity or creating complete blockages that won’t show up until the first big storm.

Scheduled Maintenance Checklist

Every year, take a walk around your retaining wall and look for trouble signs. Check that outlet screens are clear and vegetation isn’t creeping into drainage areas. Look for any settling or movement in the wall structure—small problems are much easier to fix than big ones.

Every 3-5 years, give your drainage system a thorough checkup. Flush it with water to make sure everything flows properly. If you have a long wall or multiple outlets, this might be a good time to call in professionals who have the right equipment for testing and cleaning.

When needed, address problems quickly before they get worse. Replace damaged outlet screens, clear vegetation from drainage areas, and fix any grading issues where settling has occurred. If you notice any wall movement, don’t wait—call a professional immediately.

The key to successful drainage maintenance is staying ahead of problems. A clogged outlet that gets cleared right away is a minor inconvenience. The same outlet left blocked through a winter of freeze-thaw cycles can lead to wall failure and thousands of dollars in repairs.

Frequently Asked Questions about Perforated Drain Pipe Retaining Wall

Over the years, we’ve answered thousands of questions about perforated drain pipe retaining wall systems. Here are the most common concerns homeowners and contractors ask us about.

Do I still need weep holes if I install a perforated drain pipe?

You don’t need weep holes when you have a properly installed perforated drain pipe retaining wall system. The pipe actually does a much better job than weep holes because it collects water at the lowest point behind your wall and channels it away completely.

Weep holes only work when water builds up high enough to reach them. By then, you already have hydrostatic pressure pushing against your wall. The pipe system prevents that pressure from building up in the first place.

Some contractors still install both systems for extra protection, especially on expensive walls or in areas with heavy groundwater. It’s like wearing both a belt and suspenders—probably not necessary, but it gives everyone peace of mind.

What gravel size is best around the pipe?

Angular #57 stone is your best choice for drainage around the pipe. This stone ranges from 3/4 inch down to 1/4 inch diameter and creates the perfect balance of drainage and stability.

The angular shape is crucial because the stones lock together while still leaving plenty of space for water to flow through. Round stones like pea gravel or river rock might look nicer, but they don’t interlock properly and can shift over time.

Make sure your stone is clean and washed. You want less than 10% fine particles that could wash into the pipe perforations and cause clogs. We’ve seen too many systems fail because someone used “bargain” stone that was full of dust and small debris.

Can I retrofit drainage to an existing wall without excavation?

This is probably our most heartbreaking question because the answer is usually disappointing. Limited retrofitting is possible, but it depends entirely on your wall type and how much access we have.

For segmental block walls, we can sometimes drill through the wall face and install drain pipes using specialized equipment. It’s not as effective as a full system, but it’s better than nothing if your wall is showing signs of water damage.

Unfortunately, full excavation usually makes more financial sense than trying to patch together a partial solution. I know that’s not what people want to hear when they’re looking at their failing wall, but a proper fix now prevents a complete rebuild later.

We evaluate each situation individually because every wall and site is different. Sometimes we can find creative solutions that work within your budget and give you real protection.

Conclusion

After 34 years of building retaining walls throughout Massachusetts, I can tell you that proper drainage is absolutely non-negotiable. A well-designed perforated drain pipe retaining wall system is the difference between a wall that stands strong for decades and one that becomes an expensive pile of rubble after the first heavy rain.

The math is simple: spending a few hundred dollars on proper drainage today saves you thousands in reconstruction costs later. We’ve seen too many homeowners learn this lesson the hard way when their “bargain” wall installation fails because the contractor skipped the drainage system.

Water always wins if you don’t give it a proper escape route. Whether you’re planning a new wall or looking at an existing one that’s showing signs of trouble, investing in quality drainage materials, professional installation, and regular maintenance protects both your property and your peace of mind.

Drainage isn’t just recommended—it’s essential for any retaining wall that will face water pressure. The small upfront investment in a complete drainage system pays for itself many times over in prevented failures and extended wall life.

For expert retaining wall construction that includes proper drainage from day one, visit our landscape retaining wall services page to learn more about our comprehensive approach to wall design and installation.

Gerrior Masonry & Landscape Construction—based in Woburn, MA and serving Middlesex & Essex County—can design, install, or retrofit drainage systems that keep your retaining walls standing strong for decades. With over 30 years of experience and owner oversight on every project, we ensure your perforated drain pipe retaining wall system is done right the first time, so you never have to worry about water damage again.