Cellar Door Replacement: 7 Powerful Reasons to Upgrade 2025

Why Cellar Door Replacement Matters for Your Home’s Safety and Value

Cellar door replacement is a critical home improvement that protects your basement from water damage, improves energy efficiency, and improves your property’s curb appeal. When done right, a new cellar door (also called a bulkhead door) creates a weatherproof seal that keeps moisture, pests, and drafts out while providing safe emergency egress from your basement.

Quick Answer for Cellar Door Replacement:

- Cost Range: $900-$2,000 (steel doors), $500-$1,500 (wood), $1,000-$2,000 (polyethylene/fiberglass)*

- Timeline: 4-6 hours for DIY, 2-3 hours for professional installation

- Key Signs: Rust holes, wood rot, water seepage, visible gaps, or doors that won’t stay square

- Best Materials: Steel for durability, wood for aesthetics, polyethylene for low maintenance

- When to Replace: Before water damage spreads to your foundation or basement interior

*These are average costs based on internet data and not actual costs for Gerrior Masonry services.

Your cellar door is often the weakest link in your home’s weather protection system. A failing door can lead to thousands in water damage, mold growth, and higher energy bills. The good news? Modern cellar doors are built to last decades with proper installation and minimal maintenance.

Research shows that properly installed cellar doors can prevent costly water damage while adding both security and convenience to your home. Whether you’re dealing with a rusted steel door or rotting wood panels, replacement is often more cost-effective than repeated repairs.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction, and I’ve been helping Massachusetts homeowners with cellar door replacement and bulkhead repairs for over 34 years. My team has installed hundreds of cellar doors throughout Middlesex and Essex County, and I’ve seen how the right door can transform a basement from a liability into a valuable living space.

Explore more about cellar door replacement:

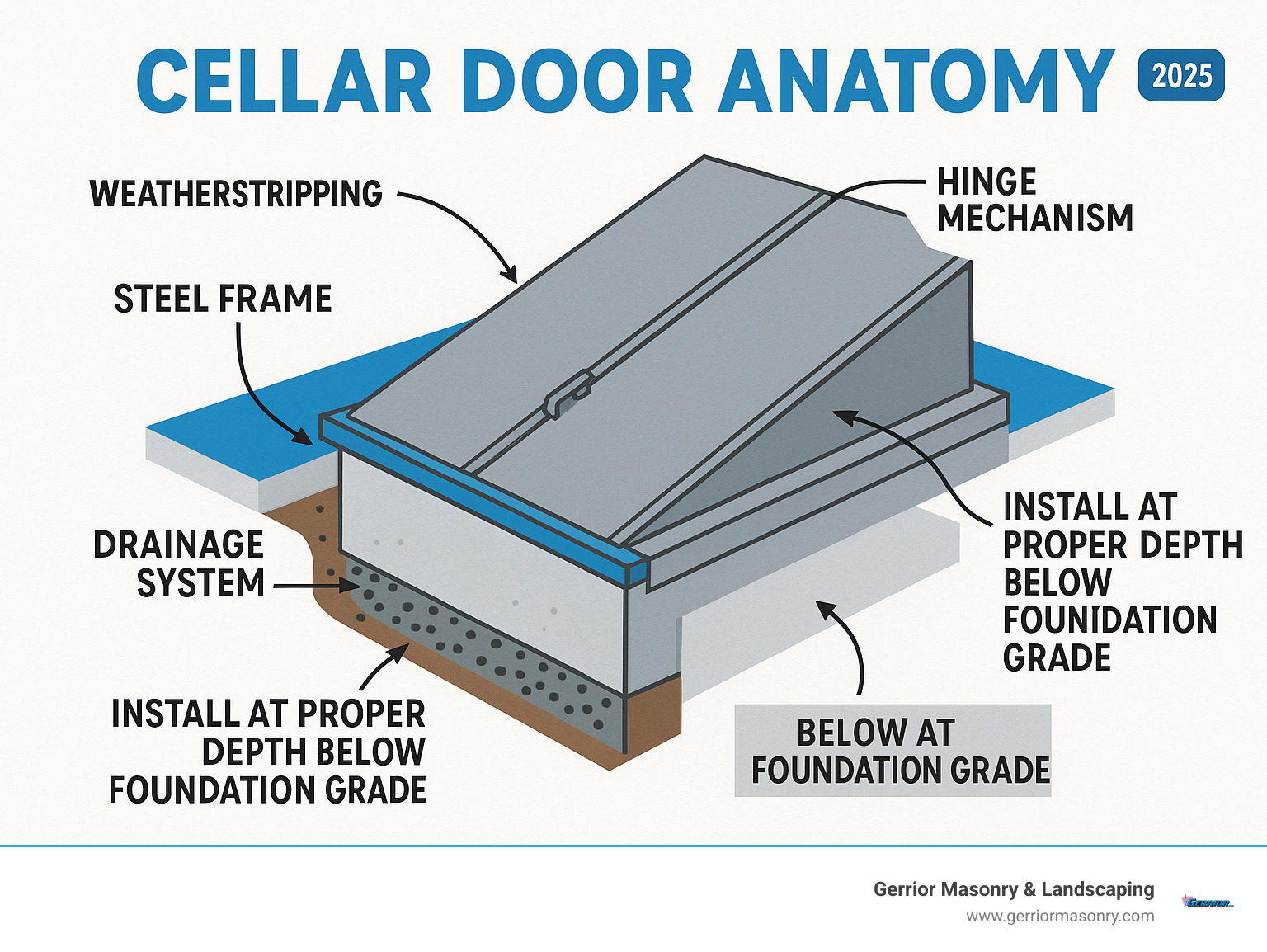

What Is a Cellar Door & Why Your Basement Depends on It

A cellar door serves as your basement’s primary connection to the outside world, providing both emergency egress and protection from the elements. Unlike interior doors, cellar doors must withstand extreme weather conditions while maintaining an airtight seal that prevents water infiltration and heat loss.

The primary functions of a cellar door include:

Emergency Egress: Building codes require basement living spaces to have at least one emergency exit. A properly sized cellar door provides the minimum 5.7 square feet of opening area needed for safe evacuation.

Storm Protection: During severe weather, your cellar door acts as a barrier against wind-driven rain, snow, and debris. The sloped design channels water away from your foundation rather than allowing it to pool against your basement walls.

Foundation Integration: Modern cellar doors tie directly into your home’s foundation system, creating a weatherproof seal that prevents frost heave and water penetration. The frame anchors deep into the concrete, distributing load forces across the foundation wall.

Walk-Out Access: For finished basements, cellar doors provide convenient access for moving furniture, appliances, and supplies without navigating narrow interior stairs. This access can significantly increase your basement’s usability and your home’s value.

Insulation and Energy Efficiency: Quality cellar doors feature weatherstripping and thermal breaks that prevent heat loss. A well-sealed door can reduce your heating costs by eliminating drafts and maintaining consistent basement temperatures.

Security: Heavy-duty hinges and locking mechanisms deter unauthorized entry while providing you with secure access to basement storage areas.

How a Bulkhead Differs From Wine-Cellar & Interior Doors

Understanding the differences between cellar door types helps you choose the right replacement for your specific needs:

Basement Egress Doors (what most people call cellar doors or bulkhead doors) are exterior-grade units designed to withstand weather exposure. They feature angled panels that shed water, heavy-duty hinges rated for frequent use, and weatherstripping systems that maintain seals despite temperature fluctuations.

Exterior Grade Construction: Unlike interior doors, cellar doors must resist UV radiation, temperature extremes, and moisture exposure. Materials are specifically chosen for outdoor durability – galvanized steel, marine-grade hardware, and UV-stable plastics.

Sloped vs. Vertical Design: Traditional cellar doors feature a sloped design that naturally sheds water and snow. This differs from vertical wine cellar doors, which prioritize airtight seals for temperature control but aren’t designed for weather exposure.

Gasket Systems: Exterior cellar doors use compression gaskets and weatherstripping designed to maintain seals despite seasonal expansion and contraction. Wine cellar doors focus on vapor barriers and thermal insulation rather than weather resistance.

The key distinction is that exterior cellar doors must function as both a building envelope component and an access point, while interior wine cellar doors only need to control temperature and humidity within a conditioned space.

Clear Signs You Need Cellar Door Replacement

Recognizing when your cellar door needs replacement can save you thousands in water damage and energy costs. Here are the most common warning signs we see in our Massachusetts service area:

Rust Holes and Corrosion: Steel doors showing rust spots larger than a quarter, or any holes that allow light to pass through, need immediate replacement. Surface rust can be treated, but structural corrosion compromises the door’s integrity.

Wood Rot and Decay: Wooden cellar doors with soft spots, crumbling edges, or visible fungal growth have lost their structural integrity. Wood that’s been repeatedly wet and dry creates ideal conditions for mold growth that can spread to your basement.

Visible Gaps and Drafts: If you can see daylight around the door frame or feel air movement when the door is closed, your weatherstripping has failed. Gaps larger than 1/8 inch allow water infiltration and significant heat loss.

Water Seepage: Water stains on your basement walls near the cellar door, or standing water after storms, indicates that your door’s drainage system has failed. This is often the first sign of more serious foundation problems.

Pest Entry Points: Gaps around the door frame provide entry points for rodents, insects, and other pests. If you’re finding unwanted visitors in your basement, check your cellar door first.

Escalating Repair Costs: When you’re spending more than $200 annually on cellar door repairs, replacement becomes more economical. Repeated fixes often indicate underlying structural problems that repairs can’t solve.

Mold Risk Indicators: Musty odors, condensation on basement walls, or visible mold growth near the cellar door suggest moisture infiltration that could lead to serious health and structural issues.

Hidden Red Flags Most Homeowners Miss

Beyond obvious damage, several subtle signs indicate impending cellar door failure:

Hinge Sag: Doors that don’t close evenly or require lifting to latch properly have worn hinges or frame distortion. This creates gaps that worsen over time.

Misaligned Latches: Hardware that doesn’t engage smoothly or requires force to operate indicates frame movement or foundation settling that affects the door’s fit.

Flaking Paint Inside Frame: Paint failure on the interior frame surfaces suggests moisture infiltration that’s compromising the door’s structural integrity from the inside out.

Concrete Curb Cracks: Hairline cracks in the concrete foundation where the door frame attaches can allow water infiltration and indicate foundation movement that affects door alignment.

These subtle signs often appear months or years before obvious failure, giving you time to plan replacement before emergency repairs become necessary.

For comprehensive bulkhead repair services, including addressing these hidden issues, visit our bulkhead and walkout repairs page.

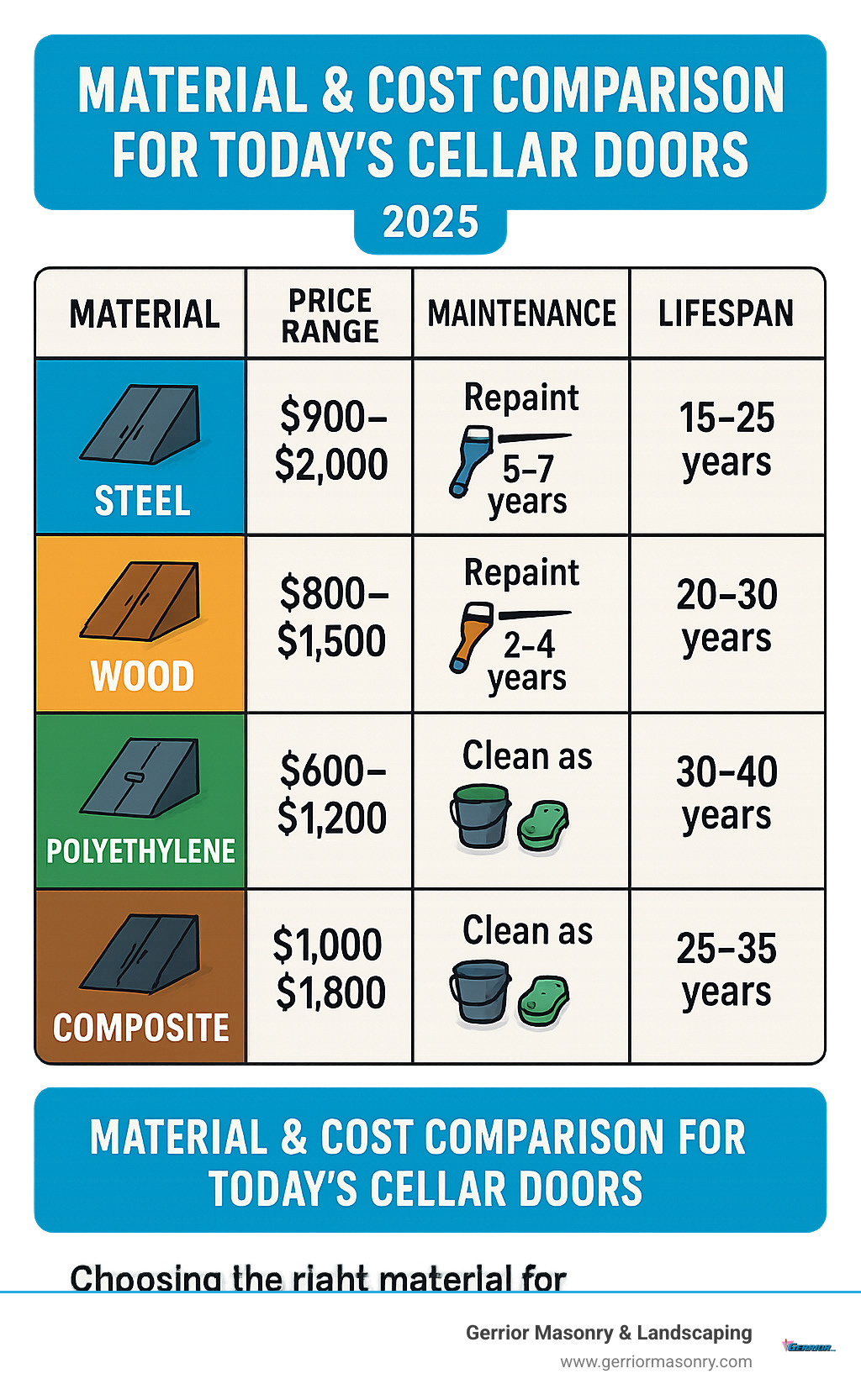

Material & Cost Comparison for Today’s Cellar Doors

Choosing the right material for your cellar door replacement involves balancing upfront costs, maintenance requirements, and expected lifespan. Based on current market data, here’s what you can expect:

Steel Cellar Doors: $900-$2,000 installed*

- Lifespan: 15-25 years with proper maintenance

- Maintenance: Repaint every 5-7 years, annual hinge lubrication

- Pros: Durable, security, moderate cost, widely available

- Cons: Rust potential, requires painting, conducts heat

Wood Cellar Doors: $500-$1,500 installed*

- Lifespan: 10-20 years depending on wood species and maintenance

- Maintenance: Annual staining/sealing, regular inspection for rot

- Pros: Natural beauty, good insulation, can be custom-built

- Cons: Weather susceptible, higher maintenance, pest attraction

Polyethylene/Fiberglass Doors: $1,000-$2,000 installed*

- Lifespan: 20-30 years with minimal maintenance

- Maintenance: Annual cleaning, occasional hardware lubrication

- Pros: Never rust, UV-stable, low maintenance, excellent insulation

- Cons: Higher upfront cost, limited color options, potential for UV degradation

Composite Doors: $1,200-$3,000 installed*

- Lifespan: 25-35 years

- Maintenance: Minimal – occasional cleaning and hardware service

- Pros: Best of all materials, superior insulation, factory warranty

- Cons: Highest cost, limited availability, specialized installation

*These are average costs based on internet data and not actual costs for Gerrior Masonry services.

Powder Coat Finishes add $200-$400 to steel doors but provide superior durability compared to standard paint. Factory-applied powder coating can last 10-15 years without touch-ups.

Warranty Considerations: Steel doors typically carry 5-10 year warranties, while polyethylene and composite doors often include 15-20 year coverage. Always verify warranty terms before purchase.

For detailed pricing on current options, check the latest cost data from industry sources.

Steel Cellar Doors—The Longevity Champ

Steel remains the most popular choice for cellar door replacement due to its balance of durability, cost, and availability. Modern steel doors feature significant improvements over older models:

Galvanized Construction: Today’s steel doors use hot-dip galvanizing that provides rust protection for decades. The zinc coating sacrificially protects the underlying steel, even if the surface is scratched.

Anti-Rust Coating Systems: Premium steel doors feature multi-layer coating systems – galvanized base, primer, and topcoat – that provide 15-20 years of rust protection with minimal maintenance.

Welded vs. Bolted Construction: Quality steel doors use continuous welding rather than bolted assemblies, eliminating weak points where water can penetrate and cause corrosion.

Mid-Range Pricing: Steel doors offer the best value proposition for most homeowners, providing professional-grade durability at moderate cost compared to premium materials.

Repaint Cycles: With proper surface preparation, steel doors can be repainted every 5-7 years to maintain appearance and protection. This flexibility allows you to update colors as your home’s exterior changes.

The key to steel door longevity is proper installation and maintenance. Doors that are correctly sealed and annually inspected can last 20-25 years with minimal repairs.

Learn more about our steel cellar doors and installation services.

Wood Cellar Doors—Classic Curb Appeal

Wood cellar doors offer best aesthetic appeal and can be custom-built to match your home’s architectural style. However, they require more maintenance and careful material selection:

Species Selection: Cedar, mahogany, and cypress are preferred for exterior cellar doors due to their natural rot resistance. These woods contain oils that repel moisture and insects.

Carpentry Skill Requirements: Wood doors require skilled installation to ensure proper fit and weatherproofing. Tongue-and-groove construction with stainless steel fasteners provides the best durability.

Stain and Seal Maintenance: Wood doors need annual inspection and re-staining every 2-3 years. Solid-color acrylic stains provide better protection than clear finishes and are easier to maintain than paint.

Insulation Value: Wood provides natural insulation properties superior to steel, helping reduce energy costs. Properly constructed wood doors can achieve R-values of 3-5.

Preservative Treatment: Any wood in contact with concrete or masonry must be treated with preservative to prevent rot. This is critical for long-term durability.

The main drawback of wood doors is their susceptibility to weather damage and the ongoing maintenance required to preserve their appearance and structural integrity.

Polyethylene & Fiberglass—No-Rust, Higher Ticket

Modern synthetic materials offer the ultimate in low-maintenance cellar door solutions, though at a premium price point:

UV-Stable Formulations: Quality polyethylene doors use UV inhibitors that prevent degradation from sun exposure. These doors maintain their color and structural integrity for decades without fading.

Molded Shell Construction: Unlike assembled doors, molded polyethylene doors are formed as single units, eliminating joints where water can penetrate. This construction method provides superior weatherproofing.

Color-Through Material: The color is integrated throughout the material rather than applied as a surface coating. This means scratches and minor damage don’t expose different-colored substrate.

Premium Cost Range: The higher upfront cost is offset by virtually no maintenance requirements and extended lifespan. Over 20-30 years, total cost of ownership often equals or beats steel doors.

Thermal Performance: Polyethylene doors provide excellent insulation properties, often outperforming steel and wood in energy efficiency testing.

The main considerations with synthetic doors are the higher initial investment and limited color options compared to painted steel doors.

DIY vs Professional Cellar Door Replacement

Cellar door replacement can be a DIY project for experienced homeowners, but it requires mid-level carpentry skills and specialized tools. Here’s what you need to know:

Required Tools:

- Angle grinder with cutting discs

- Hammer drill with masonry bits

- Level (4-foot minimum)

- Pry bar and demolition tools

- Socket wrench set

- Caulk gun and weatherproofing materials

- Safety equipment (glasses, gloves, dust mask)

Skill Level Assessment: This project requires a 5 out of 5 skill level according to industry standards. You’ll need experience with:

- Concrete cutting and drilling

- Frame alignment and leveling

- Weatherproofing and sealant application

- Heavy lifting (doors can weigh 100+ pounds)

Time Estimate: Plan for 4-6 hours for a complete replacement, plus additional time for concrete patching and finishing work.

Safety Considerations: Working with heavy steel doors and power tools requires proper safety equipment. The lifting and positioning aspects pose injury risks for inexperienced installers.

Permit Requirements: Most municipalities require permits for cellar door replacement. Check with your local building department before starting work.

Liability Factors: Improper installation can lead to water damage, foundation problems, and code violations. Consider whether the potential savings justify the risks.

Step-by-Step DIY Cellar Door Replacement

If you decide to tackle cellar door replacement yourself, follow these detailed steps:

Step 1: Remove the Old Door and Frame

- Disconnect hinges and remove door panels

- Use angle grinder to cut through frame anchors

- Pry out old frame sections with care to avoid foundation damage

- Clean debris from the opening

Step 2: Measure the Rough Opening

- Measure width, depth, and height at multiple points

- Check for square using diagonal measurements

- Note any irregularities that need correction

- Verify measurements against new door specifications

Step 3: Patch and Prepare Concrete

- Fill any holes or cracks with fast-setting concrete

- Level the foundation surface where the frame will sit

- Allow concrete to cure for at least one hour

- Clean and dampen the surface before proceeding

Step 4: Set the New Frame

- Apply self-stick membrane to pressure-treated sills

- Position frame in opening and check for level

- Use shims to adjust alignment as needed

- Mark anchor bolt locations

Step 5: Anchor the Hardware

- Drill pilot holes for masonry anchors

- Apply silicone sealant to anchor points

- Secure frame with appropriate fasteners

- Verify frame remains square and level

Step 6: Install and Adjust Doors

- Mount hinges to door panels

- Hang doors and check for proper alignment

- Adjust torsion springs for smooth operation

- Test latching mechanisms

Step 7: Weatherseal and Finish

- Apply weatherstripping around frame perimeter

- Seal all gaps with appropriate caulk

- Prime any exposed metal surfaces

- Apply finish coat according to manufacturer specifications

For replacement parts and hardware, visit our bulkhead door replacement parts page.

When to Hire a Pro for Cellar Door Replacement

Several situations make professional installation the better choice:

Structural Repairs Needed: If your foundation curb is cracked, settling, or damaged, professional masonry work is required before door installation.

Masonry Curb Rebuild: When the concrete foundation needs reconstruction or significant repair, specialized tools and expertise are necessary.

Custom Sizes Required: Non-standard openings may require custom fabrication or frame modifications that exceed typical DIY capabilities.

Heavy Steel Doors: Large or premium steel doors can weigh 150+ pounds and require specialized lifting equipment and multiple installers.

Warranty Considerations: Professional installation often includes warranty coverage that protects your investment and ensures code compliance.

Time Constraints: Professional installation typically takes 2-3 hours compared to a full day for DIY work.

At Gerrior Masonry & Landscape Construction, we handle all aspects of cellar door installation, from foundation repairs to final weatherproofing. Our experienced team ensures your new door meets all local codes and provides decades of reliable service.

Learn more about our bulkhead door installation services.

Sizing, Style & Code Must-Knows

Proper sizing and code compliance are critical for successful cellar door replacement. Here’s what you need to know:

Egress Code Requirements: Basement living spaces must have emergency exits with minimum 5.7 square feet of opening area. The opening must be at least 20 inches wide and 24 inches high, with a maximum sill height of 44 inches above the basement floor.

Rise and Run Clearances: The area in front of the cellar door must provide adequate clearance for emergency egress. Most codes require a minimum 36 inches of clear space in front of the door.

Standard Sizing Systems: Most manufacturers use sizing systems like the BILCO “C” and “O” series:

- “C” Series: Sloped doors for flat foundations (most common)

- “O” Series: Flat doors for sloped foundation walls

- Sizes typically range from 4 feet to 6 feet wide

Custom Fabrication Options: Non-standard openings may require custom doors, which typically cost 25-50% more than standard sizes but ensure proper fit and code compliance.

Child-Safe Latches: Modern cellar doors include safety features that prevent accidental opening by children while allowing emergency egress by adults.

Drainage Slope Requirements: Proper installation requires a minimum 1/4 inch per foot slope away from the door to prevent water accumulation.

For professional door sizing assistance, check the door sizing tool recommended by industry professionals.

Choosing a Door That Fits & Looks Right

Beyond code compliance, consider these factors for optimal results:

Measure Twice, Order Once: Accurate measurements are critical. Measure the width, depth, and height at multiple points to account for foundation irregularities.

Match Your Roofline: Choose door styles that complement your home’s architecture. Traditional sloped doors work with most styles, while contemporary flat doors suit modern homes.

Color Coordination: Select colors that harmonize with your home’s exterior. Neutral colors like white, gray, or earth tones provide timeless appeal.

Security Upgrades: Consider keyed locks, reinforced hinges, and tamper-resistant hardware for improved security.

Accessibility Features: If basement access is needed by elderly or mobility-impaired individuals, consider doors with assisted opening mechanisms.

For a complete selection of styles and options, visit our basement access doors page.

Care, Maintenance & Common Mistakes

Proper maintenance extends your cellar door’s lifespan and prevents costly repairs. Here’s our recommended maintenance schedule:

Annual Inspection Checklist:

- Check weatherstripping for wear or damage

- Inspect hinges and hardware for rust or looseness

- Examine frame for cracks or separation from foundation

- Test door operation and latch alignment

- Clear debris from drainage areas

Repaint Schedule: Steel doors should be repainted every 5-7 years, or when surface rust appears. Sand lightly, prime bare metal, and apply high-quality exterior paint.

Lubricate Moving Parts: Apply white lithium grease to hinges and latch mechanisms twice yearly. Avoid petroleum-based lubricants that attract dirt.

Snow and Ice Management: Keep doors clear of snow accumulation. Use plastic shovels to avoid scratching surfaces, and apply ice melt products sparingly.

Avoid Concrete Contact: Never allow concrete, mortar, or masonry materials to contact door surfaces, as they can cause accelerated corrosion.

Common Installation Mistakes to Avoid:

Overtightening Anchor Bolts: Excessive torque can crack concrete or distort the door frame, leading to alignment problems and water infiltration.

Skipping Vapor Barriers: Failing to install proper vapor barriers between steel frames and concrete allows moisture infiltration that causes premature rust.

Inadequate Drainage: Poor grading or blocked drainage systems cause water accumulation that can undermine the foundation and door integrity.

Wrong Fastener Types: Using standard bolts instead of galvanized or stainless steel fasteners creates corrosion points that weaken the installation.

Storage Hacks to Extend Door Life

Simple protective measures can significantly extend your cellar door’s lifespan:

Leaf Guards: Install mesh screens over drainage areas to prevent leaf accumulation that blocks water flow.

De-icing Pads: Place rubber mats or wooden boards under doors during winter to prevent ice formation that can damage hinges and seals.

Breathable Covers: During extreme weather, temporary covers can protect doors from hail or debris while allowing air circulation to prevent condensation.

Seasonal Adjustments: Adjust door tension and alignment seasonally to account for foundation movement and temperature changes.

These simple steps can add 5-10 years to your door’s service life while reducing maintenance requirements.

Conclusion

Cellar door replacement is a critical investment in your home’s safety, energy efficiency, and value. A properly installed door protects your basement from water damage, provides emergency egress, and can significantly improve your home’s curb appeal.

The key benefits of timely replacement include:

Improved Home Safety: Modern cellar doors meet current egress codes and include safety features that protect your family during emergencies.

Return on Investment: Quality cellar doors typically return 70-80% of their cost in increased home value, while preventing costly water damage that can exceed the door’s cost many times over.

Energy Savings: Properly sealed doors can reduce heating costs by 10-15% by eliminating basement drafts and maintaining consistent temperatures.

Peace of Mind: Knowing your basement is protected from weather, pests, and unauthorized entry provides invaluable peace of mind.

Whether you choose steel for durability, wood for aesthetics, or polyethylene for low maintenance, the most important factor is proper installation by experienced professionals who understand local codes and conditions.

At Gerrior Masonry & Landscape Construction, we’ve been helping Massachusetts homeowners with cellar door replacement for over three decades. Our skilled team ensures your new door provides decades of reliable service while meeting all safety and building code requirements.

Ready to protect your basement and improve your home’s value? Contact us today for a free consultation and estimate. We’ll help you choose the right door for your needs and budget, then install it with the craftsmanship and attention to detail that comes from 34 years of experience.

For more information about our comprehensive bulkhead services, visit our bulkhead replacement page.

Gerrior Masonry & Landscape Construction is based in Woburn, MA, proudly serving homeowners throughout Middlesex and Essex County, Massachusetts.