Heat Resistant Cement: Best Options 2025

Why Heat Resistant Cement is Essential for High-Temperature Projects

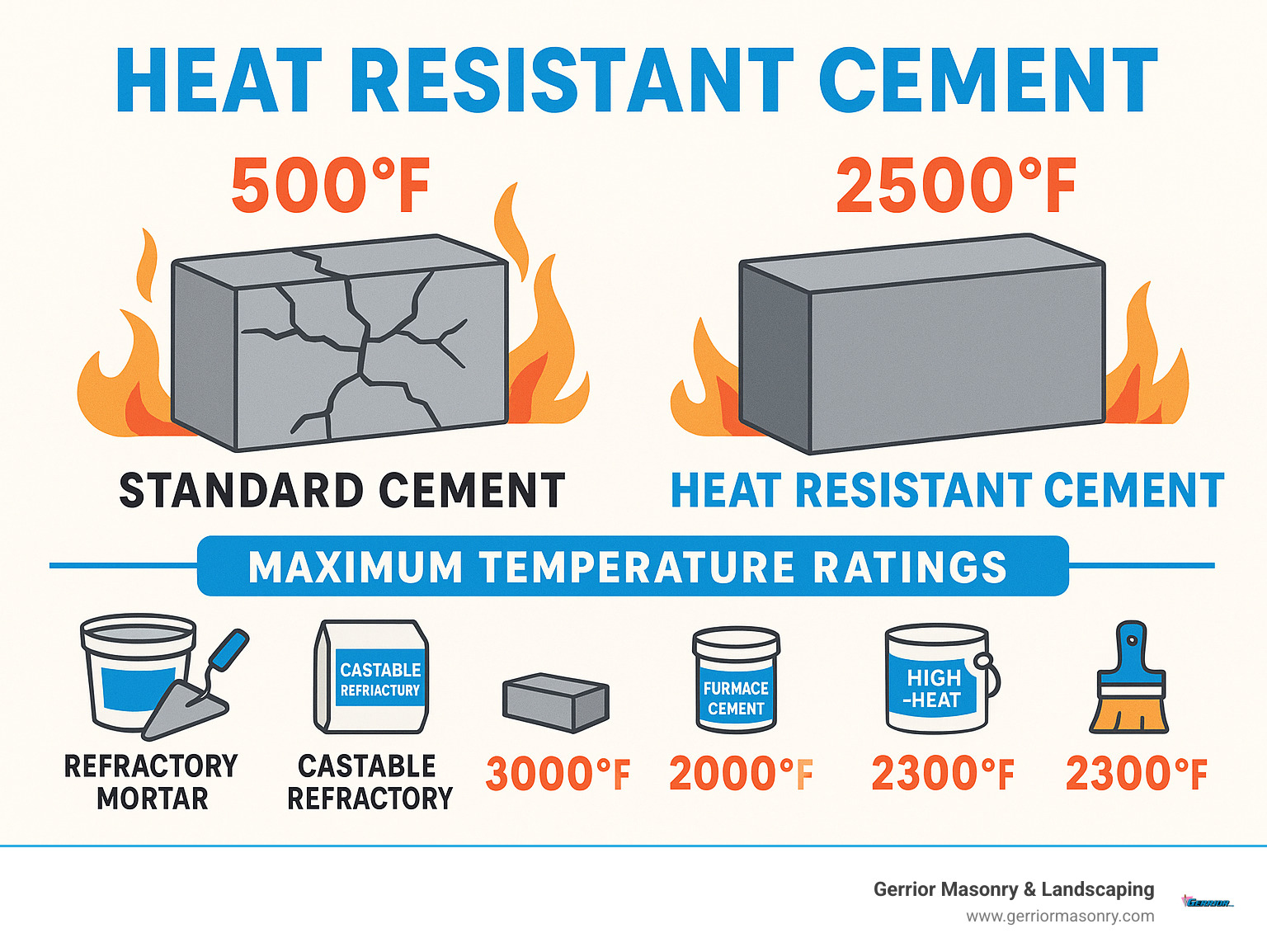

Heat resistant cement is a specialized building material designed to withstand extreme temperatures without cracking, crumbling, or losing structural integrity. Unlike standard concrete that begins to deteriorate at temperatures above 500°F, heat resistant cement can handle continuous exposure to temperatures ranging from 2,000°F to 3,000°F.

Quick Reference Guide for Heat Resistant Cement:

- Refractory Mortar: Best for laying firebricks and filling joints (up to 2,550°F)

- Castable Refractory: Ideal for casting custom shapes and thick applications (up to 3,000°F)

- Furnace Cement: Perfect for sealing cracks and small repairs (up to 2,000°F)

- High-Heat Coating: Used for protective coatings on metal surfaces (up to 2,300°F)

The key difference lies in the composition. While regular mortar uses Portland cement as a binder, heat resistant cement relies on calcium aluminate, refractory clays, and specialized aggregates that maintain their strength under extreme heat.

Common applications include:

- Fireplace construction and repair

- Chimney repointing

- Wood-fired pizza ovens

- Outdoor fire pits

- Industrial furnace linings

Safety is critical when working with high-temperature applications. Standard concrete can explode when heated rapidly due to trapped moisture, making the right material selection essential for both performance and safety.

As Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp., I’ve worked with heat resistant cement for over three decades in fireplace repairs, chimney construction, and custom outdoor fire features throughout Massachusetts. My experience has shown that choosing the right high-temperature material is crucial for projects that will face extreme heat exposure.

Basic heat resistant cement glossary:

What is Heat Resistant Cement and How Does It Work?

Using regular concrete to line a firebox is a recipe for disaster. Heat resistant cement is engineered to withstand extreme temperatures that would make ordinary concrete crumble. While standard concrete fails above 500°F, heat resistant cement can handle up to 3,000°F in some formulations.

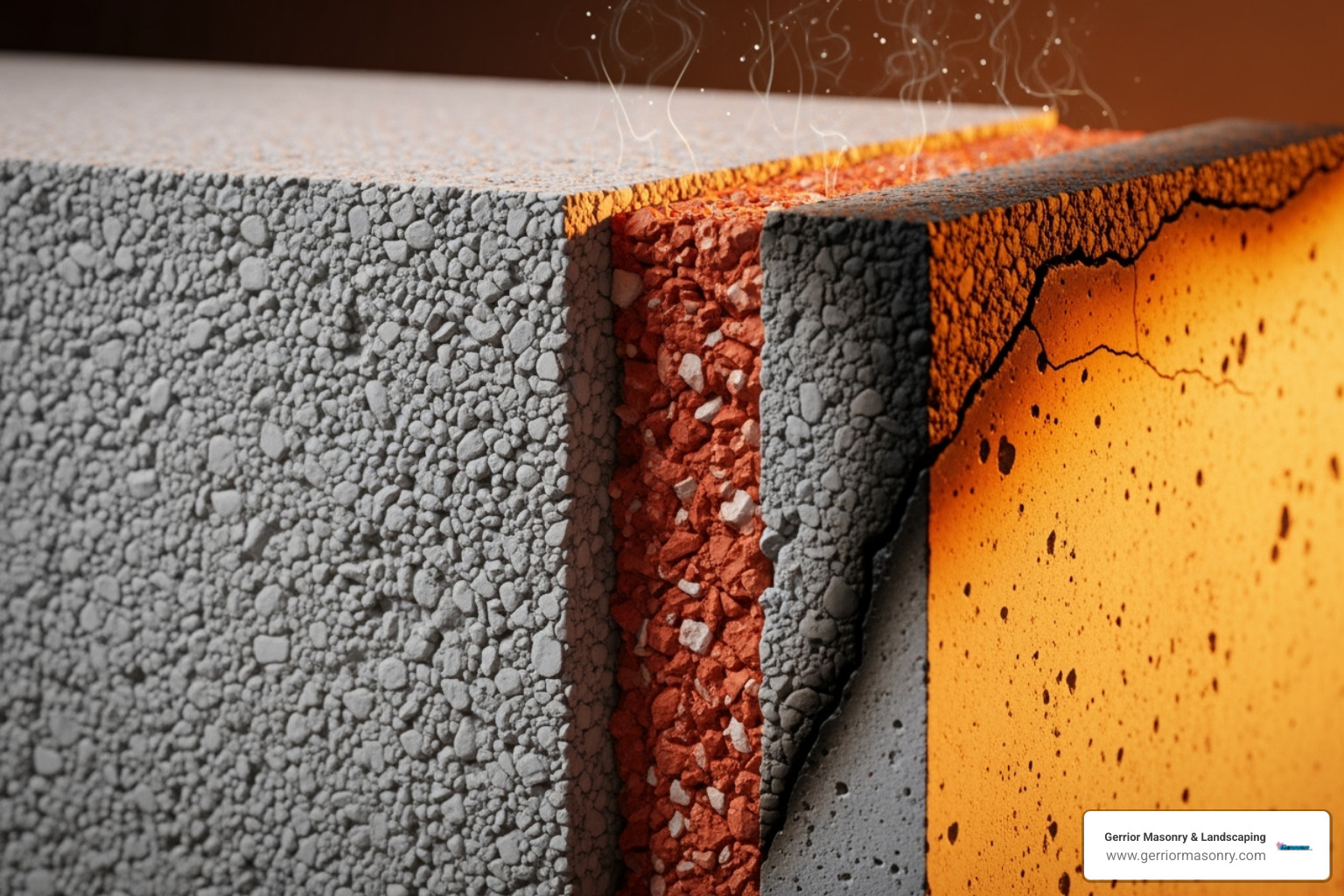

The secret lies in its composition. Instead of Portland cement, heat resistant cement uses calcium aluminate cement as its binder, which maintains strength at high temperatures. This is combined with refractory aggregates like fireclay, alumina, and silica—materials proven in furnaces and kilns. These ingredients provide excellent resistance to thermal shock, the stress from rapid heating and cooling that cracks regular concrete. The high-temperature binders ensure the cement maintains structural integrity even when red-hot, preventing cracks and crumbling.

For anyone working on hearth projects, Adhesives for the Hearth provides excellent guidance on selecting the right materials for different applications.

Key Differences from Standard Concrete and Mortar

The differences between heat resistant cement and regular concrete extend far beyond temperature tolerance.

- Chemical composition: Regular concrete uses Portland cement, which breaks down under high heat. Heat resistant cement uses specialized binders like calcium aluminate that maintain their strength.

- Heat degradation: Trapped moisture in regular concrete can turn to steam and cause it to explode or spall when heated rapidly. Heat resistant cement is formulated to release moisture safely.

- Thermal expansion properties: Regular concrete expands and contracts dramatically, leading to cracks. Heat resistant cement uses aggregates with low thermal expansion for stability.

- Curing process: Many heat resistant cements are air-setting or require specific heat curing schedules, unlike standard concrete which just needs moisture and time.

- Strength characteristics: Regular concrete loses strength at high temperatures, while quality heat resistant cement maintains its strength even when red-hot.

- Application differences: Heat resistant mortars are for thin joints, while castable versions are for thick, monolithic structures.

The Science Behind High-Temperature Performance

The performance of heat resistant cement comes from its refractory materials and how they work together.

- Fireclay: A special clay with high levels of alumina and silica, it forms the foundation of many mixes, maintaining strength at high temperatures.

- Alumina (aluminum oxide): This ceramic material is responsible for high temperature ratings (from 2,000°F to 3,000°F) and provides resistance to abrasion and chemical attack.

- Silica: In specialized forms, silica helps create a stable matrix that bonds the refractory materials together.

These materials contribute to key performance metrics. Temperature ratings indicate the maximum continuous temperature the cement can withstand. Cold crushing strength measures its durability at room temperature, while chemical resistance is vital for resisting acidic flue gases in chimneys and other corrosive environments.

A Guide to High-Temperature Masonry Products

Choosing the right heat resistant cement can be confusing with terms like “refractory mortar,” “castable refractory,” and “furnace cement.” These aren’t interchangeable; each is a specific tool for a particular job. Understanding the difference between products for bonding firebricks versus casting a solid structure is key to a successful project. This guide clarifies the main categories to help you select the right material.

Understanding Refractory Mortar vs. Heat Resistant Cement

Refractory mortar is the glue for firebricks, used in fireplaces or pizza ovens. It’s applied in thin joints, typically 1/8″ to 3/8″ thick, as thick joints can be a weak point. It comes in pre-mixed tubs for convenience or as a dry mix that requires adding water.

In contrast, heat resistant cement (often called castable refractory) is for casting custom shapes and creating monolithic structures. It’s applied in thick layers (1.5 to 2 inches minimum) and is ideal for filling large gaps or forming solid components that need to withstand direct flame.

Furnace Cement and Castable Refractory Explained

Furnace cement is a pre-mixed paste used for minor repairs and sealing. With excellent sealant properties, it’s perfect for patching small cracks in fireplaces or sealing gaps around stove pipes, typically handling temperatures up to 2,000°F. It’s a convenient solution for quick homeowner repairs.

Castable refractory is a heavy-duty, industrial-grade material for building or repairing large structures like kiln linings or custom forges. It’s poured like concrete to a minimum thickness of 1.5 to 2 inches and can withstand temperatures over 2,500°F. Its complex curing process makes it best suited for industrial or highly specialized projects.

Common Applications: From Your Backyard to Industrial Furnaces

Heat resistant cement is incredibly versatile, used in projects from backyard fire features to industrial furnaces. In my three decades of masonry, I’ve seen that choosing the right high-temperature material is essential for any construction facing serious heat. For any masonry construction project that will face high temperatures, we offer comprehensive masonry services to ensure your investment stands the test of time.

Residential Projects

Most homeowners encounter heat resistant cement in residential projects.

- Fireplace construction and repair: The firebox can exceed 1,000°F, requiring refractory materials to protect the home. Proper materials, as used in our fireplace construction and repair services, prevent costly future damage.

- Chimney repointing and repair: Mortar joints in the flue must withstand hot, corrosive gases. We use rated materials for all our chimney repairs to ensure longevity.

- Wood-fired pizza ovens: These require castable refractory to handle temperatures of 800-900°F and rapid heating and cooling cycles.

- Outdoor fire pits: While not as hot as pizza ovens, using heat-resistant materials is crucial for durability against thermal shock. We’ve built many outdoor fire pits that last for years.

- Home forges and pottery kilns: These advanced projects require industrial-grade castable refractories to handle extreme heat.

Industrial High-Temperature Applications

In the industrial world, heat resistant cement is mission-critical where failure can shut down operations.

- Furnace linings: Steel mills and glass plants use thick castable refractory barriers to contain heat exceeding 3,000°F.

- Boiler repairs: Linings in power plants must endure continuous high temperatures and pressure.

- Incinerators: These require specialized cement that resists both extreme heat and chemical attack from corrosive byproducts.

- Foundry applications: Equipment handling molten metal, like ladles and crucibles, needs materials that resist heat without contaminating the metal.

- Other uses: Include reactor insulation in chemical plants and protective high-temperature coatings for equipment.

Proper Application and Curing for Maximum Durability

Even the best heat resistant cement will fail if not applied correctly. Proper surface preparation, mixing, and curing are essential for durability. Following a meticulous process is key to creating a project that provides decades of reliable service.

Step-by-Step Application Guide

Correct application technique is crucial for a lasting project.

- Start with a spotless surface. Remove all old mortar, dust, and grease using a wire brush or scraper. Good adhesion requires a clean base.

- Dampen the substrate. Bricks should be damp, not soaking wet. This prevents them from drawing moisture from the fresh cement too quickly.

- Mix in small batches. These cements set fast. Mix only what you can use in 15-20 minutes, following the manufacturer’s water ratios precisely.

- Apply correctly. For refractory mortar, maintain a thin, consistent joint (1/8″ to 3/8″). For castable refractory, apply at least 1.5 inches thick.

- Finish smoothly. A smooth, even surface cures better and is less prone to cracking.

The Critical Curing Process

Patience during curing is non-negotiable.

- Allow 24 hours for air drying. Before any heat exposure, let the heat resistant cement air cure. This allows initial chemical bonds to form.

- Perform a slow initial firing. This is a critical step. Gradually heat the material over several hours, starting around 250°F and slowly increasing to operating temperature. This prevents steam explosions from trapped moisture and thermal shock.

- Recognize DIY recipe limitations. While you can find DIY high-temperature mortar recipes online, they cannot match the performance of commercial products for critical applications.

- Know when to call professionals. For projects involving structural elements, extreme temperatures, or safety risks, professional installation is the safest choice. The cost of doing it right is always less than fixing a failure.

Frequently Asked Questions about Heat Resistant Cement

What is the highest temperature refractory cement can handle?

The temperature rating depends on the specific product. For most residential projects like fireplaces or pizza ovens, standard products rated for 2,000°F and 2,550°F are sufficient. For example, Sakrete High-Heat Mortar is rated up to 2,550°F. For industrial applications, specialized heat resistant cement can exceed 3,000°F. Always check the manufacturer’s specifications for your project and choose a product rated well above your expected operating temperature.

Can I use heat resistant cement for an outdoor BBQ or fire pit?

Yes, heat resistant cement is ideal for outdoor fire features. The key is to select a product that becomes non-water soluble after curing, making it durable against rain and snow. It’s also designed to handle thermal cycling—the dramatic temperature swings between a hot fire and cold weather that would crack regular concrete. For all our outdoor masonry projects, we use materials rated for exterior use and follow precise curing procedures to ensure longevity.

Is refractory mortar waterproof?

This is a common question, and the answer is typically no. Most refractory mortars are not designed to be waterproof. While they excel at handling heat, prolonged exposure to water can cause them to soften, erode, or lose strength. For outdoor projects, this means the refractory material often needs protection, such as a roof over a pizza oven or a protective sealant on exposed surfaces. Always read the manufacturer’s specifications, especially for outdoor use, as some specialized products may offer better water resistance.

Conclusion: Choosing the Right Material for a Safe and Lasting Project

Choosing the right heat resistant cement is the most critical factor for a safe, durable high-temperature project. As we’ve covered, these materials are scientifically formulated to withstand heat that would destroy standard concrete. The key is to match the product to the job: refractory mortar for bonding firebricks, castable refractory for thick structural forms, and furnace cement for sealing and minor repairs.

Safety is paramount. Using the wrong material or skipping the critical curing process can lead to dangerous failures. While DIY recipes exist, professional-grade materials are essential for applications exceeding 2,500°F, where the risks of failure are too high. An investment in quality materials and correct application is an investment in safety and longevity.

For expert masonry work, including fireplace and chimney repairs, trust the skilled team at Gerrior Masonry & Landscaping. With over 30 years of experience and owner oversight on every project, we handle high-temperature challenges safely and effectively.

Gerrior Masonry & Landscaping is based in Woburn, MA, and proudly serves communities throughout Middlesex and Essex County, Massachusetts.