how to install paver stones walkway: 7 Powerful Steps 2025

The Perfect Path: Creating Your Own Paver Stone Walkway

There’s something magical about a well-crafted paver stone walkway. It doesn’t just connect two points on your property—it welcomes visitors, improves your home’s character, and creates that “wow” factor when people approach your front door. As a homeowner looking to boost your curb appeal, learning how to install paver stones walkway might be one of the most rewarding DIY projects you’ll tackle.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction Corp. Over my 34+ years installing thousands of paver walkways throughout Massachusetts, I’ve refined the techniques that make these projects successful in our unique New England soil and climate conditions. The good news? With some patience and the right approach, this is absolutely something you can accomplish yourself.

Creating your own paver walkway involves seven key steps that transform your yard into a showcase of craftsmanship:

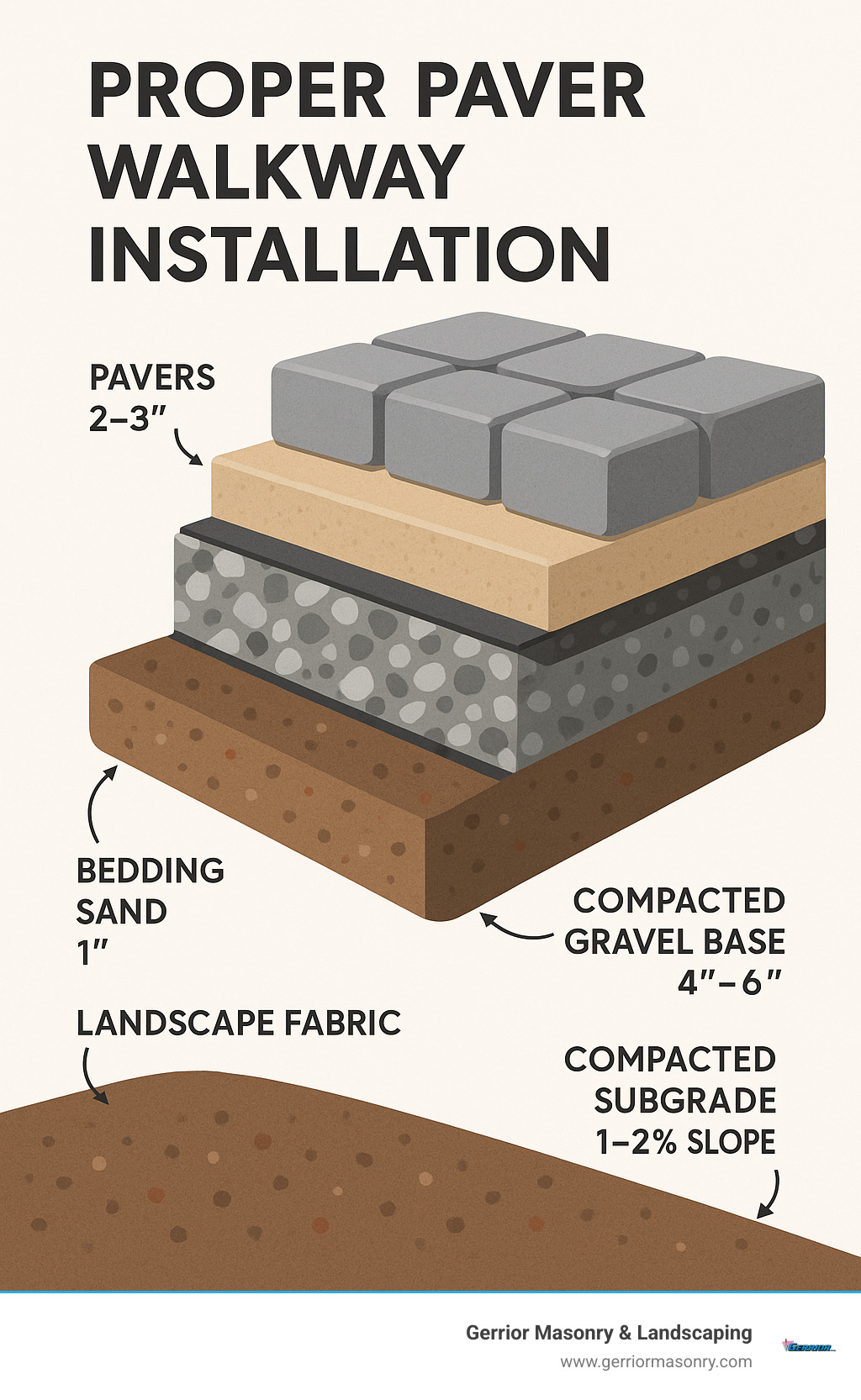

First, you’ll mark and excavate your path to about 8 inches deep, creating the foundation for your project. Next, installing landscape fabric prevents future weed headaches (trust me, this step saves countless hours later). Then comes the critical base layer of gravel – 4-6 inches compacted in stages for stability. A 1-inch layer of leveling sand creates the perfect bed for your pavers, which you’ll then arrange in your chosen pattern. Securing everything with edge restraints prevents shifting, and finally, filling joints with polymeric sand locks everything in place after compaction.

What I love about paver walkways is their accessibility for DIYers with basic skills. You don’t need to be a masonry expert—just someone willing to invest in proper preparation. And that preparation truly makes the difference between a walkway that lasts decades and one that shifts and settles after the first frost.

The infographic above shows what many homeowners miss—the critical layering system that makes a paver walkway stable through New England’s harsh freeze-thaw cycles. Each layer serves a purpose, from drainage to stability to preventing weed growth.

When clients ask me about how to install paver stones walkway projects, I emphasize that proper sloping (that 1-2% grade) might seem minor, but it’s what keeps puddles from forming on your beautiful new path during our notorious spring rains. It’s these little details that separate professional-quality results from disappointing ones.

In the following sections, we’ll dive deeper into material selection, design considerations, and detailed installation techniques that will help you create a walkway you’ll be proud to show off to neighbors and guests alike. With some sweat equity and attention to detail, you’ll create a pathway that improves your home’s value and your everyday enjoyment of your property.

Paver Stones 101: Types, Benefits & Must-Have Tools

When planning your walkway project, understanding your paver options is the first step toward creating a path that perfectly complements your home. I’ve installed thousands of walkways over the years, and I’ve seen how the right paver choice can make all the difference.

Types of Pavers

Concrete pavers are the darling of DIY projects, and for good reason. They’re budget-friendly at $2-5 per square foot, come in countless shapes and colors, and are forgiving for first-timers. Many of my clients are surprised by how realistic today’s concrete pavers look—some can barely be distinguished from natural stone!

Natural stone pavers bring best character to your landscape. Whether it’s the cool blue tones of bluestone or the warm earthy hues of flagstone, these materials offer a timeless appeal. They’re pricier ($5-20 per square foot) and can be trickier to work with due to their irregular shapes, but the results are simply stunning.

Clay brick pavers offer that classic, warm red look that never goes out of style. Priced between $3-8 per square foot, they maintain their rich color even after years of Massachusetts weather. There’s something wonderfully traditional about a brick walkway that continues to charm homeowners.

As Roger Cook, a respected landscape contractor once told me, “For DIYers, I recommend the running-bond pattern using concrete pavers. It requires the fewest cuts, so it goes down the fastest.”

Benefits of Paver Walkways

When clients ask me why they should choose pavers over poured concrete, I point out several key advantages. Durability tops the list—a properly installed paver walkway can last 25-50 years with minimal upkeep. The repairability factor is huge too; if a single paver gets damaged or stained, you can simply replace that one piece rather than redoing the entire walkway.

I especially emphasize the slip resistance of textured pavers for New England homes, where icy conditions are a concern. The aesthetic appeal of pavers allows for creative expression through various patterns and color combinations, while some systems offer permeability for better drainage. Finally, pavers have natural flexibility to accommodate ground movement without cracking—particularly important in our freeze-thaw climate.

Essential Tools for Installation

For a successful how to install paver stones walkway project, having the right tools makes all the difference. You’ll need basic measuring tools like a tape measure, string line, stakes, and mason’s line to ensure straight, properly aligned edges.

For ground preparation, gather a shovel, rake, wheelbarrow, and both a plate compactor (rentable from local equipment shops) and hand tamper. Leveling tools are critical—both 2-foot and 4-foot levels will help you maintain proper drainage slope.

Don’t forget safety gear! Gloves, eye protection, ear protection, and a dust mask are non-negotiable, especially when cutting pavers with a diamond blade saw or masonry saw. You’ll also need a rubber mallet for setting pavers, landscape fabric for weed prevention, PVC pipes and a 2×4 for screeding sand, plus edge restraints and spikes to keep everything in place.

One tip I always share with DIYers: proper compaction is essential. As a colleague with over 20 years of installation experience puts it, “If you can drive a steel spike into the gravel with anything less than a 3-pound sledgehammer, the gravel is not compacted enough.” That’s wisdom worth its weight in gold when you’re learning how to install paver stones walkway for the first time.

The right paver choice combined with proper tools sets the foundation for a walkway that will improve your home’s curb appeal for decades to come.

Designing Your Walkway: Layout, Patterns & Proper Drainage

The magic of a beautiful paver walkway starts long before the first stone is laid. Taking time to thoughtfully plan your layout, pattern, and drainage now will save you countless headaches later—and ensure your pathway is both gorgeous and functional for years to come.

Determining Width and Layout

When deciding how wide to make your walkway, think about how it will actually be used in daily life:

For a cozy single-person path, aim for at least 3 feet wide. If you want two people to stroll comfortably side-by-side (think holding hands with your partner or walking with a friend), you’ll want 4-5 feet of width. And if accessibility matters for wheelchairs or mobility devices, plan for at least 3.5 feet with 5-foot diameter turning spaces.

“I always tell homeowners to err on the wider side,” says Joe Gerrior. “In my 30+ years of installing walkways, I’ve never had a client complain their path was too wide—but I’ve had plenty wish they’d gone bigger!”

Marking your walkway’s boundaries is surprisingly simple. Grab some stakes and string, and outline your proposed path. For straight sections with perfect right angles, the classic 3-4-5 method works beautifully: measure 3 feet along one line, 4 feet along the perpendicular line, and if the diagonal between these points measures exactly 5 feet—voilà, you’ve got a perfect 90-degree corner.

For those dreamy curved walkways that add character to your landscape, just lay out a garden hose in a pleasing curve, then trace along it with spray paint or even kitchen flour. Stand back and adjust until it feels right—this is your chance to be creative!

Choosing a Pattern

Your paver pattern isn’t just about looks—it affects installation difficulty and even how your walkway holds up over time:

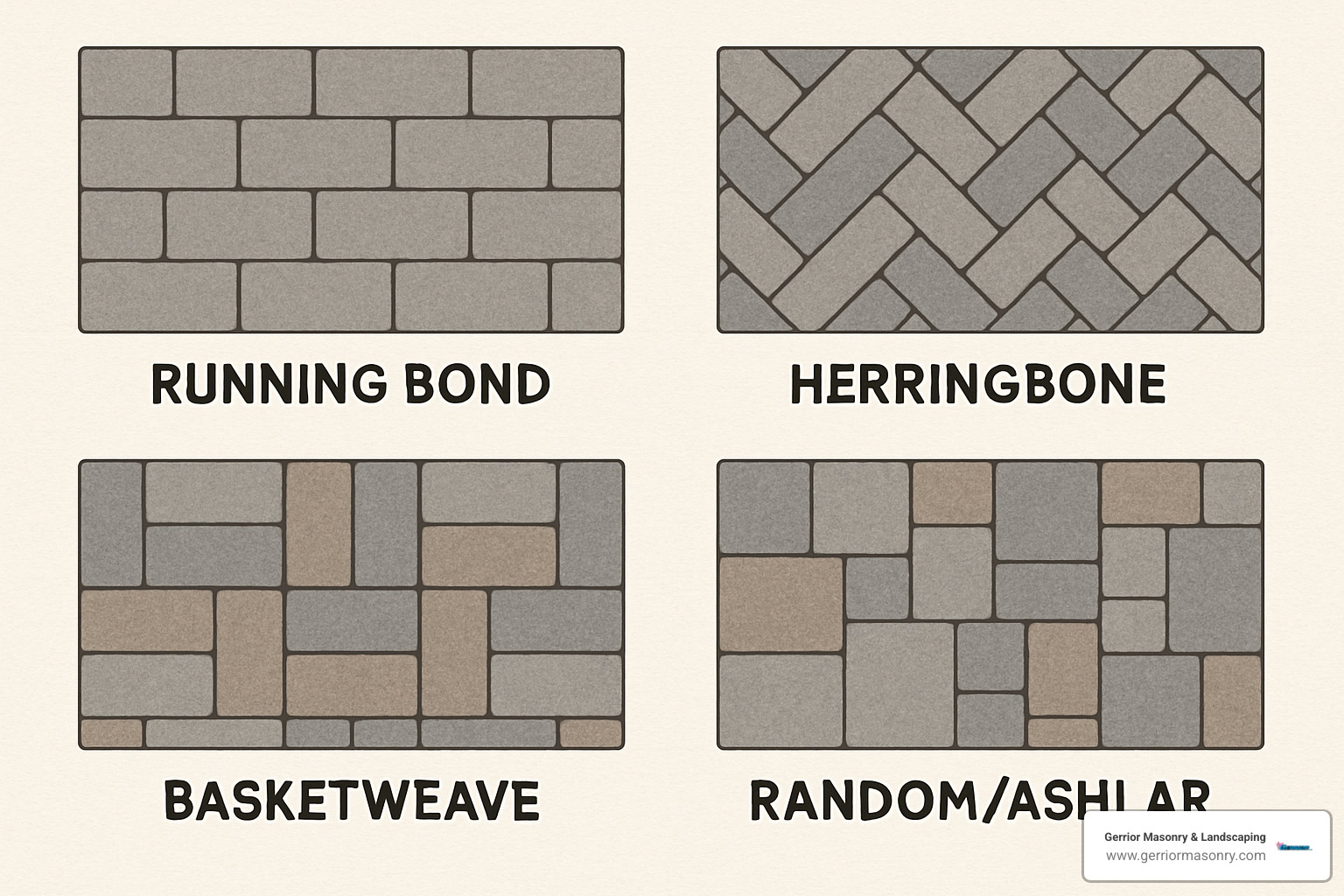

Running Bond is the classic brick wall pattern with each row offset by half a paver. It’s the friendliest option for DIY beginners and requires minimal cutting. Perfect if you’re tackling how to install paver stones walkway for the first time.

Herringbone creates an eye-catching zigzag at either 45° or 90° angles. Beyond looking sophisticated, this pattern provides exceptional interlocking strength that resists shifting—ideal for areas with freeze-thaw cycles like we have in Massachusetts.

Basketweave alternates pairs of pavers to mimic woven fabric. It strikes a nice balance between visual interest and moderate installation difficulty.

Random/Ashlar combines multiple paver sizes for a natural stone appearance. Stunning but challenging—I’d recommend saving this for your second or third paver project.

“Before committing to a pattern, lay out a small section on flat ground as a test run,” suggests Joe. “It’s much easier to adjust your design before you’ve dug the first shovel of dirt.”

Ensuring Proper Drainage

Water is both essential for life and the silent enemy of hardscaping. Proper drainage isn’t optional—it’s what prevents pooling water, slippery surfaces, and potential damage to your home’s foundation.

Every paver walkway should slope 1-2% away from structures. In practical terms, this means for every 100 inches of walkway, you need a drop of 1-2 inches. For a typical 4-foot wide path, aim for about ¼ to ½ inch of drop across the width.

The math is straightforward: Slope % = (Rise ÷ Run) × 100. So if your walkway drops 2 inches over 100 inches: (2 ÷ 100) × 100 = 2% slope.

Industry standards allow walkways to slope up to 5% (5-inch drop over 100 inches) as long as the surface remains slip-resistant. For patios, keep it at 2% maximum for comfort while standing.

“One of the most common mistakes I see in DIY walkways is inadequate slope,” notes Joe. “A level-looking walkway might seem desirable, but without proper pitch, you’ll end up with puddles, ice in winter, and potentially serious water issues.”

A simple trick: attach a small spacer to one end of your level to maintain consistent slope as you work. This low-tech solution ensures water will flow exactly where you want it—away from your walkway and home.

Don’t forget to consider installing weed fabric beneath your base layers. This small additional step prevents unwanted vegetation from disrupting your beautiful pathway over time.

For more expert guidance on designing the perfect walkway for your property, check out our detailed design tips or use this handy slope calculator to get your drainage just right.

How to Install Paver Stones Walkway: Step-by-Step Guide

Now that you’ve planned your walkway, it’s time to bring your design to life. Following these steps carefully will ensure a professional-looking result that will last for years to come.

Step 1 – Ground prep for how to install paver stones walkway

Proper ground preparation is the foundation of a successful paver installation. I can’t stress this enough – skipping or rushing this step is the number one reason walkways fail prematurely.

Before you dig, always call 811 at least 72 hours ahead to have your utility lines marked. Trust me, hitting a gas or electric line is not the kind of excitement you want on a weekend project!

For a typical paver walkway, you’ll need to excavate about 8 inches deep. This might seem excessive, but this depth accommodates your gravel base (4-6 inches), bedding sand (1 inch), and the pavers themselves (2-3 inches).

Set up stakes and string at the exact height of your finished walkway to serve as your guide throughout the project. This simple step will save you countless headaches later.

Different soil types need different approaches. Clay soils often need deeper excavation and better drainage, while sandy soils drain well but might need extra compaction. After excavating, compact the soil thoroughly – if you’re leaving footprints when walking on it, it’s not compacted enough.

As one of my customers once joked, “I didn’t realize I was getting a workout when I signed up for this project!” Yes, this step is labor-intensive, but it’s worth every drop of sweat.

Step 2 – Base building

Think of your base as the foundation of a house – if it’s weak, everything above it will eventually fail. A proper base provides stability and drainage to prevent your beautiful new walkway from shifting, sinking, or heaving during freeze-thaw cycles.

Start by laying landscape fabric over your compacted soil. This simple step prevents the gravel from mixing with the soil below and helps stop weeds from finding their way up through your walkway. Make sure to overlap the seams by 12-18 inches.

Next, add your crushed stone or gravel in thin layers (we call these “lifts”) of about 2-3 inches each. The secret to a solid base is compacting each layer thoroughly before adding the next. For most home walkways, a total base thickness of 4-6 inches works well, though areas with poor drainage or harsh winters might need more.

When compacting, make multiple passes in different directions with your plate compactor. You’re aiming for at least 95% Proctor density – which is a fancy way of saying “really well compacted.” A good test: if you can drive a steel spike into the gravel with anything less than a 3-pound sledgehammer, keep compacting!

Remember to maintain your planned slope throughout the base layer. Regular checks with a long level and a spacer will keep you on track.

Step 3 – Screeding the bedding layer

Now for the bedding layer – this is the smooth, cushiony surface that your pavers will actually sit on. It should be exactly 1 inch thick after compaction.

Start by setting up screeding guides – 1-inch diameter PVC pipes or metal conduit laid on your compacted base. These guides should follow the same slope as your base to ensure proper drainage.

Pour concrete sand (also called mason’s sand) between your guides, spreading it a bit higher than needed. Don’t use play sand or all-purpose sand – they won’t provide the stability you need. Now comes the satisfying part: use a straight 2×4 that extends beyond both sides of your walkway and pull it across the guides with a sawing motion to level the sand. It’s almost like frosting a cake!

Once you’ve screeded the sand to perfection, treat it like fine art – no walking on it or disturbing it. If you must step on it, be sure to re-screed that area afterward. And double-check that your bedding layer maintains that critical ¼-inch per foot slope for drainage.

Step 4 – Edge restraints & setting the pattern

Edge restraints are like the unsung heroes of paver installation – invisible in the finished project but absolutely essential for preventing your pavers from spreading and shifting over time.

For most DIY installations, plastic or metal edging works beautifully. Place it along the outside edge of where your pavers will go, securing it with 10-12 inch spikes every foot or so. If you’re working with curves, plastic edging offers more flexibility.

Now for the exciting part – laying your first row of pavers! Begin at a fixed edge (like your house) or at the lowest point if you’re on a slope. Take extra time with this starter row, as it sets the pattern for everything that follows. Use a string line to ensure it’s perfectly straight.

As you continue laying pavers, stretch mason’s lines every 10 pavers or so to keep your rows straight. For curved walkways, a flexible garden hose makes an excellent guide. Think of this step as setting up dominos – if the first few are aligned perfectly, the rest will follow suit.

Step 5 – Laying & cutting: the heart of how to install paver stones walkway

This is where your walkway really starts to take shape. Place each paver snugly against its neighbors, allowing only about ⅛-inch gap between them. Set them straight down into the sand – never slide them into place, as this disturbs your carefully prepared bedding.

When you reach edges or curves, you’ll need to cut pavers to fit. Mark your cut line clearly with a pencil or chalk, then use a masonry saw with a diamond blade for straight cuts. For curves, an angle grinder with a diamond blade works well, or you can make multiple straight cuts to approximate the curve.

Safety first! Always wear eye protection, ear protection, and a dust mask when cutting pavers. Consider wet-cutting if possible to reduce dust – your lungs will thank you.

After placing each paver, use a rubber mallet to gently tap it into place, ensuring it’s level with surrounding stones. Every few rows, place a long straightedge across your pavers to check for high or low spots. It’s much easier to fix these issues now than later.

As one of my customers once said, “It’s like putting together a giant puzzle, except you get to create the pieces as you go!”

Step 6 – Joint fill, compaction & clean-up

You’re in the home stretch! Before adding joint sand, make a pass with a plate compactor fitted with a rubber pad to protect your pavers. This settles them into the bedding sand and reveals any pavers that need adjustment.

Next, sweep polymeric sand into the joints between pavers. This specialized sand contains polymers that harden when moistened, locking your pavers in place and preventing weeds from taking hold. Make sure the sand completely fills all joints, then sweep the excess off the surface. A leaf blower on low setting works wonders for removing sand from the paver surfaces.

Following the manufacturer’s instructions, lightly mist the walkway with water to activate the polymers in the sand. The key word here is “lightly” – too much water can wash out the sand or create a hazy film on your pavers.

After the polymeric sand has set, check for any areas where it might have settled and add more as needed. Make one final inspection to ensure everything looks perfect before the sand fully hardens.

The change from bare ground to beautiful walkway is truly remarkable – and even more satisfying when you can proudly say, “I built that myself!” With proper installation, your paver walkway will provide decades of beauty and function for your home.

Finishing Touches, Sealing & Maintenance

Your new paver walkway is installed, but a few finishing touches and proper maintenance will ensure it looks beautiful for years to come.

To Seal or Not to Seal?

The age-old question every paver owner faces: should you seal your walkway? While not mandatory, sealing offers several compelling benefits worth considering.

Sealing your pavers can dramatically improve and preserve their color, keeping that fresh-installed look for years. It also creates a protective barrier that prevents staining from fallen leaves, spilled drinks, or the occasional oil drip from your lawnmower.

“I’ve seen two identical walkways installed at the same time – one sealed, one not – and after five years, the difference is remarkable,” says Joe Gerrior. “The sealed walkway still looks vibrant while the unsealed one has faded and collected various stains.”

Beyond aesthetics, a quality sealer stabilizes your joint sand and significantly reduces erosion during heavy rains. This means less maintenance for you and fewer opportunities for weeds to take root or ants to colonize those tiny spaces between pavers.

However, sealing isn’t without drawbacks. You’ll need to reapply every 2-3 years depending on weather conditions and foot traffic. Some sealers, particularly high-gloss varieties, can create a slippery surface when wet – not ideal for New England’s rainy springs and snowy winters. Sealers can also alter the natural appearance of certain pavers, especially natural stone types that have their own inherent beauty.

If you decide to seal, patience is key. Wait at least 30 days after installation to allow efflorescence (that whitish powder that sometimes appears) to emerge naturally. Clean the pavers thoroughly and ensure they’re completely dry before applying your chosen sealer.

Ongoing Maintenance

With proper care, your how to install paver stones walkway project will remain beautiful and functional for decades. Think of maintenance as protecting your investment.

A simple weekly sweep removes debris before it can stain or allow moss to develop. For general cleaning, a garden hose with a spray nozzle usually does the trick. For tougher stains, a bit of mild dish soap and a soft brush will handle most messes without damaging your pavers.

“The best maintenance is preventative maintenance,” I often tell my clients. “Five minutes of sweeping each week saves hours of scrubbing later.”

Make it a habit to conduct an annual inspection each spring. Look for any pavers that have shifted, sunk, or risen above their neighbors. Catching these issues early prevents them from spreading and makes repairs much simpler.

Pay special attention to your joint sand during these inspections. Areas where sand has eroded should be replenished promptly with polymeric sand to maintain the walkway’s structural integrity. This is especially important after harsh winters, when freeze-thaw cycles can loosen the sand.

For winter care, use plastic snow shovels rather than metal ones, which can scratch or chip your pavers. If ice forms, calcium chloride is far gentler on your walkway than traditional rock salt, which can damage concrete pavers over time.

Fixing Common Issues

Even the best-installed walkways occasionally develop problems, but most are easily fixable.

Sunken pavers typically result from inadequate base preparation or erosion of the base material. The fix is straightforward: carefully remove the affected pavers, add and compact additional bedding sand to bring the area level with surrounding pavers, then reinstall. This is where those few extra pavers you saved during installation come in handy!

Raised pavers usually indicate tree roots growing underneath or frost heave in colder climates. This requires removing the pavers, addressing the underlying cause (perhaps trimming roots or improving drainage), leveling the area, and reinstalling.

Stained pavers respond to different treatments depending on the stain type. For oil stains, try a poultice made from kitty litter or sawdust soaked in a degreaser – spread it over the stain, let it sit overnight, then sweep away. For organic stains like leaf tannins, a gentle solution of 10 parts water to 1 part household bleach usually does the trick.

“But what if you only have a small area to repair and not the entire walkway? Yes, it’s the same process,” explains our senior installer. “Lift and clean the affected pavers, level the base with paver sand, re-lay and tamp the pavers, then finish with polymeric sand.”

For stubborn issues or larger repairs, don’t hesitate to call professionals. At Gerrior Masonry & Landscaping, we’ve seen and fixed virtually every paver problem imaginable throughout Middlesex and Essex County.

More info about walkway repairs

Costs, Permits & Common Mistakes to Avoid

Understanding what you’ll spend and potential pitfalls will help you steer your paver walkway project successfully. As a homeowner tackling this project, you’ll want to have a clear budget and plan before breaking ground.

Cost Considerations

I’ve seen paver walkway costs vary tremendously based on material choices, design complexity, and whether you’re doing it yourself or hiring professionals.

If you’re taking the DIY route, expect to spend between $8-15 per square foot for basic concrete pavers. This jumps to $15-25 per square foot when using premium concrete pavers or natural stone. These figures include materials, equipment rentals, and other supplies you’ll need.

For professional installation, the investment typically starts around $20-35 per square foot for standard materials and straightforward patterns. Premium materials or intricate designs can push that range to $35-70 per square foot.

“Most homeowners don’t realize that material selection can double or even triple their project cost,” explains Joe Gerrior. “Natural stone looks stunning but requires more skill to install properly and costs significantly more than concrete pavers.”

These are average costs based on internet data, not actual costs for Gerrior Masonry services. Your specific project might fall outside these ranges depending on:

- Local material availability and pricing

- Your site’s condition (sloped yards cost more)

- Complexity of your design pattern

- Excavation depth needed

- Additional features like lighting or special borders

Permits and Regulations

Before you start moving dirt, take time to check local requirements. Nothing derails a project faster than finding you needed a permit halfway through!

Most towns don’t require permits for simple walkways, but this changes if your project includes retaining walls over a certain height (typically 2-3 feet) or affects drainage patterns. A quick call to your local building department will clarify what’s needed.

If you live in a neighborhood with an HOA, review their guidelines before purchasing materials. Some associations have strict rules about hardscaping materials, colors, and designs.

“I’ve had clients who completed beautiful walkways only to receive violation notices from their HOA,” shares a landscape designer. “Always check your covenants first.”

Don’t forget to call 811 before digging to have underground utilities marked. This free service prevents costly and dangerous accidents. Allow at least 72 hours for utility companies to respond before starting excavation.

Common Mistakes to Avoid

After installing hundreds of paver walkways, I’ve seen the same mistakes trip up DIYers time and again. Avoiding these pitfalls will save you time, money, and frustration.

Under-compaction is the number one reason walkways fail prematurely. Many homeowners skimp on the plate compactor rental or try to get by with hand tamping. “A plate compactor isn’t just a nice-to-have—it’s absolutely essential for a lasting installation,” emphasizes a hardscape professional. Make multiple passes over each base layer until it’s rock solid.

Ignoring proper slope leads to puddles, ice patches, and potentially water damage to adjacent structures. Maintain at least a 1-2% slope (about ¼ inch per foot) away from your house or other buildings. Use a level with a measured spacer to check your slope regularly during installation.

Skipping edge restraints might seem like a minor shortcut, but it guarantees your pavers will spread and shift over time. Those plastic or metal edging pieces locked in with spikes every 12 inches are what keep your pattern tight and true for years.

Excessive bedding sand is a common rookie mistake. “Too much sand beneath pavers leads to uneven settling and movement,” warns a veteran installer. “Stick to exactly 1 inch of sand—no more, no less.”

Inadequate joint fill between pavers invites weeds and allows pavers to shift. Make sure your polymeric sand completely fills the joints from bottom to top, then activate it properly with a light misting of water according to manufacturer instructions.

“One mistake I see repeatedly is homeowners rushing the process,” notes Joe Gerrior. “How to install paver stones walkway projects require patience at each stage—especially during compaction and ensuring proper drainage.”

By avoiding these common errors and taking time to research local requirements and costs, you’ll set yourself up for a successful project that improves your home’s value and curb appeal for years to come.

For professional installation that avoids all these pitfalls, check out our professional installation services or get more details about typical paver walkway costs.

Frequently Asked Questions about Paver Stone Walkways

How thick should the gravel base be?

One of the most common questions I hear from homeowners tackling their first how to install paver stones walkway project is about base thickness. For a typical residential walkway, you’ll want a gravel base that’s 4-6 inches thick after compaction. But like many aspects of hardscaping, the “right” answer depends on your specific situation.

If you’re dealing with heavy clay soil or an area with poor drainage, you might need to bump that up to 6-8 inches. Similarly, if you live in a region with harsh freeze-thaw cycles (hello, New England winters!), a thicker base provides better protection against frost heave.

“The gravel base is typically 4 inches thick; the sand base is 1-1.5 inches thick; the thickness of pavers varies,” explains a professional installer I’ve worked with for years.

Remember the golden rule of base installation: always build it in layers. Apply 2-3 inch “lifts” of gravel, thoroughly compacting each layer before adding the next. This approach creates a much more stable foundation than trying to compact one thick layer all at once.

Do I really need to seal the pavers?

I get this question all the time, and my answer is always the same: technically no, but you’ll probably be happier if you do.

Sealing isn’t absolutely necessary for your paver walkway to function properly. The pavers will still handle foot traffic just fine without a sealer. However, applying a quality sealer offers several significant benefits that most homeowners appreciate:

- It improves and preserves the original color of your pavers

- It creates a protective barrier against stains from leaves, oil, and other outdoor culprits

- It helps keep your polymeric sand firmly in place

- It makes it much harder for weeds to take root between pavers

- It simplifies maintenance and cleaning

Without sealer, your pavers will weather more quickly and likely require more frequent maintenance. If you do choose to seal, plan on reapplying every 2-3 years to maintain that protection.

As one of my colleagues notes, “Sealing is essential around pools to keep grit out of pumps,” though for standard walkways it remains a beneficial option rather than a strict requirement.

Can I install pavers over existing concrete?

Yes! This approach can save you considerable time and effort compared to demolishing and removing an existing concrete walkway. However, there are some important conditions the concrete must meet:

First, the existing concrete needs to be structurally sound with no major cracks or damage. Small hairline cracks are okay, but anything wider than a pencil indicates potential structural issues.

Second, the concrete must have proper slope for drainage. If water pools on your current walkway, that problem will persist with pavers on top.

Third, the concrete should be stable and not subject to settling or frost heave. If it’s constantly moving, your pavers will too.

If your concrete meets these criteria, the installation process is simpler than starting from scratch:

- Thoroughly clean the concrete surface

- Apply approximately ¾ inch of fine leveling sand

- Install edge restraints along the perimeter

- Lay your pavers and complete the project as you normally would

“It’s possible, and totally doable, to cover old concrete with pavers. There’s just a few caveats: the existing concrete must be solid, intact, and relatively flat without large cracks or bumps,” explains a contractor who specializes in concrete overlays.

One important consideration: this method will raise the height of your walkway by at least 2-3 inches (the thickness of the sand plus pavers). You’ll need to plan for how this affects steps, doorways, or other connecting surfaces.

Conclusion

There’s nothing quite like the satisfaction of stepping back to admire a beautiful paver walkway you’ve installed with your own two hands. The change from a simple dirt path to an neat, durable walkway can truly lift your home’s appearance and functionality.

Throughout this guide, we’ve walked through every step of how to install paver stones walkway projects—from initial planning and material selection to the final touches that make your walkway shine. The techniques we’ve covered represent decades of professional experience distilled into actionable advice for homeowners.

Patience truly is a virtue when it comes to paver installation. Those extra minutes spent ensuring your base is properly compacted, your slope is correct, and your pattern is aligned will reward you with years—even decades—of trouble-free enjoyment. As we often tell our clients, “Measure twice, dig once!”

Your new walkway isn’t just functional; it’s an investment in your property that typically returns 80-90% of its cost in home value. More importantly, it creates that warm welcome for family and friends that makes a house truly feel like home.

If you find yourself overwhelmed by the scope of the project or encounter challenging site conditions, don’t hesitate to call in professional help. Sometimes the wisest DIY decision is knowing when to bring in an expert. At Gerrior Masonry & Landscaping, we’ve helped countless homeowners across Massachusetts transform their outdoor spaces with beautiful, lasting hardscapes.

Whether you tackle this project yourself or partner with professionals, your new paver walkway will provide a lifetime of enjoyment with minimal maintenance. The path to curb appeal starts with a single paver—and ends with a walkway you’ll be proud to show off for years to come.

Gerrior Masonry & Landscape Construction Corp. is based in Woburn, MA, and proudly serves clients throughout Middlesex and Essex County, Massachusetts.