Walkway Installation: 5 Powerful Steps for Stunning Results 2025

Why Professional Walkway Installation Transforms Your Property

Walkway installation is a fundamental landscaping project that can dramatically improve your home’s curb appeal, safety, and functionality. For homeowners considering this upgrade, here’s what you need to know:

Quick Guide to Walkway Installation:

1. Planning: Measure area, determine width (36″ minimum), and mark path layout

2. Material Selection: Choose from concrete ($8-15/sq ft), pavers ($10-30/sq ft), or natural stone ($12-50/sq ft)

3. Excavation: Dig 4-6″ deep trench following your layout

4. Base Preparation: Add 3-4″ of crushed stone, compact thoroughly

5. Installation: Lay materials in chosen pattern, add edge restraints, fill joints

A well-designed walkway does more than connect spaces—it guides visitors safely to your door, prevents mud tracking, and creates visual harmony between your home and landscape. When properly installed, walkways can last 50-100 years with minimal maintenance.

I’m Joe Gerrior, owner of Gerrior Masonry & Landscape Construction, and I’ve personally overseen thousands of walkway installation projects during my 34+ years in the masonry and landscaping industry throughout Massachusetts. My team and I have refined the installation process to ensure lasting results that improve both the beauty and value of your property.

Easy Walkway Installation glossary:

– how to install paver stones walkway

– inexpensive stepping stone walkway ideas

– installing flagstone stepping stones

Step 1: Plan & Design Your Walkway Installation

The foundation of any successful walkway installation begins with thoughtful planning. After installing hundreds of walkways throughout Middlesex and Essex counties, I’ve learned that taking time at this stage prevents headaches later and ensures a result you’ll love for decades.

Start with a thorough site assessment. Take a leisurely stroll around your property with a notepad in hand. Notice where people naturally walk, existing trees or gardens you want to highlight, and any problem spots like poor drainage or steep slopes. Pay attention to how sunlight moves across your yard throughout the day – this affects both material choices and planting options alongside your new path.

Sketching your layout comes next. Don’t worry about artistic talent here – simple drawings work fine! For a real-world preview, grab a garden hose or can of marking paint to outline your walkway directly on the ground. This simple trick has saved many homeowners from “I wish we’d made it wider” regrets after installation.

When checking slopes, remember our golden rule: aim for a ¼-inch drop per foot of walkway. This provides perfect drainage without creating a tripping hazard or an uncomfortable walking experience. A basic level and string will help you measure existing slopes so you can plan accordingly.

Choosing the Best Layout for Your Walkway Installation

Your walkway design should balance practicality with visual appeal:

Straight paths create a formal, architectural feel and provide the most direct route between points. They’re perfect for traditional home styles and when efficiency matters most.

Garden curves add visual interest and feel more natural in the landscape. They invite visitors to slow down and enjoy the journey through your property.

Step intervals become important on sloped properties. For comfortable walking, aim for consistent rises between 6-7 inches and treads (the flat part) around 12-14 inches deep.

Lighting pockets should be planned now, not as an afterthought. Strategic lighting improves safety and creates beautiful nighttime ambiance.

Width is crucial for both comfort and accessibility. While the Americans with Disabilities Act (ADA) requires a minimum of 36 inches for wheelchair access, I typically recommend 48 inches for main walkways. This allows two people to comfortably walk side-by-side and creates a more welcoming approach to your home.

Before grabbing your shovel, handle the legal details. Check with your local building department about permit requirements for your specific project. And always – without exception – call 811 before digging to locate underground utilities. Here in Massachusetts, this isn’t just good advice; it’s required by law and protects you from potentially dangerous and expensive accidents.

For creative inspiration and material ideas that complement your home’s architecture, check out our Paver Walkway Ideas page.

Step 2: Estimate Costs, Pick Materials & Gather Tools

Let’s talk dollars and sense for your walkway installation project. As a homeowner, you’ll want a clear picture of what you’re investing in before breaking ground. Based on my 30+ years of experience helping Massachusetts families transform their properties, here’s the real scoop on costs and materials:

| Material | Cost Range (per sq ft) | Pros | Cons | Lifespan |

|---|---|---|---|---|

| Concrete | $8-25 | Affordable, versatile | Can crack, repairs obvious | 25-50 years |

| Pavers | $10-30 | Easy repairs, variety of styles | Higher initial cost | 50-100 years |

| Natural Stone | $12-50 | Unique appearance, durability | Most expensive, installation complexity | 100+ years |

| Gravel | $2-6 | Inexpensive, DIY-friendly | Requires regular maintenance, not wheelchair-friendly | 5-10 years |

For perspective, a typical entrance walkway measuring 3′ x 20′ (60 square feet) could cost anywhere from $480 for simple concrete to $3,000 for premium natural stone—and that’s just materials! According to national averages, professional installation typically adds $40-$50 per square foot, covering labor, equipment, and those essential extras like base materials and edging.

If you’re a weekend warrior tackling this yourself, don’t forget to budget for those easily overlooked items. A plate compactor rental will set you back $70-100 per day, and you’ll need proper safety gear (your eyes and lungs will thank you later). Always plan for 5-10% extra material—trust me, you’ll be grateful for those spare pavers when you accidentally crack one or need to make an unexpected cut.

Delivery isn’t free either—budget $100-$300 depending on how far you are from suppliers and how much material you’re ordering. For the truly budget-conscious, a simple gravel path runs about $100 per 10 feet, making it the most wallet-friendly option.

Your tool checklist should include:

– Basic digging tools (shovels and rakes)

– Measuring tools (tape measure, string line)

– Leveling equipment (bubble level and stakes)

– A trusty rubber mallet

– Appropriate cutting tools for your chosen material

– That rented plate compactor I mentioned earlier

At Gerrior Masonry, we believe in transparent pricing and helping you understand exactly what you’re paying for. While these industry averages give you a starting point, your actual costs may vary based on your specific property conditions, design choices, and material selections.

Want a deeper dive into paver walkway costs specifically? We’ve got you covered: More info about How Much Does It Cost to Build a Paver Walkway?

For those who love research, Home Depot offers detailed pricing on various masonry materials that can help inform your budget planning: Scientific research on material pricing

The numbers shared here reflect national averages based on industry data—not actual quotes from Gerrior Masonry. Your project might fall above or below these ranges depending on your specific needs and choices.

Step 3: Excavate & Build a Rock-Solid Base

The most critical—yet often overlooked—aspect of walkway installation is proper base preparation. In our 30+ years of experience, we’ve found that most walkway failures stem from inadequate base work, not the pretty materials on top.

Start by excavating to the proper depth. For standard residential walkways, dig a trench 4-6 inches deep, plus the thickness of your surface material. Here in Massachusetts, with our notorious freeze-thaw cycles, you may need to go deeper—up to 8-9 inches—to get below the frost line and prevent winter heaving.

After excavation, here’s your roadmap to success:

First, line the trench with geotextile fabric. This simple step prevents soil from mixing with your base material and keeps ambitious weeds at bay. Think of it as the unsung hero of your walkway’s longevity!

Next, add 3-4 inches of crushed stone across the entire area. Be sure to use ¾-inch crushed stone or gravel with angular edges—not rounded pea gravel, which will shift over time. The angular pieces lock together like a natural puzzle.

Now comes the non-negotiable step: thorough compaction. Rent a plate compactor and make multiple passes in different directions until you achieve 95-98% compaction. Your neighbors might wonder about the noise, but they’ll envy your non-sinking walkway for decades to come! Proper compaction eliminates air gaps and prevents future settling that leads to those annoying dips and bumps.

Don’t forget to maintain that critical ¼-inch per foot slope away from structures. This gentle grade is barely noticeable to the eye but ensures water runs off rather than pooling or flowing toward your home’s foundation.

For pavers and some stone installations, add a 1-inch layer of concrete sand as your setting bed. Level it perfectly using screed rails and a straight board—this is your last chance to create a truly flat surface.

Finally, install edge restraints to prevent lateral movement. These humble borders maintain the integrity of your walkway over time, keeping everything neat and contained through seasonal changes.

Pro Tips for Base Prep in Walkway Installation

Our team at Gerrior Masonry has refined these techniques through thousands of projects:

Soil testing pays dividends. Clay soils often need additional drainage solutions to prevent water accumulation. Sandy soils might need less excavation but require more compaction to create stability.

Consider a French drain option for problematic areas. Installing a French drain alongside or beneath your walkway prevents water accumulation that can silently undermine your base over time.

Watch those weather windows. Avoid base preparation during heavy rain or when temperatures hover near freezing. Ideal conditions are dry days with temperatures between 50-80°F—which means planning ahead in our New England climate!

Test your compaction quality with a simple trick: walk across the compacted base—there should be minimal to no visible footprints. Professional installers use density tests, but this visual check works well for homeowners.

The base represents about 70% of the work but determines 90% of your walkway’s longevity. Those hours spent on proper base preparation might not make for exciting before-and-after photos, but they’re the difference between a walkway that lasts for decades and one that needs repairs after a few seasons.

More info about How to Build a Paver Walkway on a Slope

Step 4: Lay, Cut & Lock Your Surface Materials

With a properly prepared base, you’re ready for the most visible part of your walkway installation: laying your chosen surface materials. This is where all your careful planning and prep work starts to pay off!

Begin at a fixed edge (like your house foundation or driveway) and work outward. For pavers, you’ll first need to establish your pattern. Over the years at Gerrior Masonry, we’ve found these patterns to be crowd favorites:

Running-bond gives you that classic brick-like appearance that never goes out of style. It’s straightforward to install and has stood the test of time for a reason.

Herringbone adds wonderful visual interest while providing excellent structural strength through interlocking. This pattern truly lifts the look of any walkway.

Basket-weave offers a decorative, traditional feel that complements colonial and craftsman-style homes beautifully.

Flagstone crazy-pave creates that organic, natural appearance that blends seamlessly with garden landscapes.

When laying your materials, use string guides and spacer sticks to maintain consistent gaps. Most pavers should have about a ¼-inch gap, while natural stone spacing may vary based on your design vision.

Cutting is almost always necessary to complete your pattern, especially around edges and curves. Make sure you’re using the right tools for your material:

For concrete pavers, a diamond blade wet saw or masonry saw works best. Natural stone typically requires a diamond blade wet saw or you can use traditional hammer and chisel techniques for a more rustic look. When working with brick, a brick set chisel or masonry saw will get the job done nicely.

Safety first! Always wear eye protection, hearing protection, and a dust mask when cutting. I recommend making cuts away from your installation area to prevent dust from settling on your freshly laid work surface.

Once all materials are placed, it’s time for my favorite part – locking everything together:

- Sweep polymeric sand into the joints between pavers. This specialized sand contains binding agents that activate with water.

- Run a plate compactor over the surface to settle the sand fully into the joints (this is oddly satisfying to watch!).

- Add more sand as needed, sweeping away any excess.

- Mist with water according to the manufacturer’s instructions. This activates the binding agents, creating firm yet slightly flexible joints that resist weeds and insects.

According to research from industry leaders, proper joint stabilization can extend the life of your walkway by 15-20 years by preventing material migration and limiting water infiltration. That’s value you can literally walk on!

Popular Patterns for Walkway Installation

Your pattern choice impacts both how your walkway looks and how it functions. Visual rhythm created by patterns can make spaces feel larger or guide the eye toward focal points like your front door or a garden feature.

Slip resistance varies between patterns too. Herringbone patterns with smaller pavers typically offer more grip than large format pavers – something to consider for our rainy Massachusetts springs and snowy winters.

If you’re thinking about wheelchair accessibility, choose patterns with minimal lips or transitions. We always recommend creating wider turning pads (60 inches minimum) at directional changes to accommodate mobility devices comfortably.

At Gerrior Masonry, we often create custom pattern combinations that incorporate borders, soldier courses (pavers set perpendicular to the main field), or inset designs that complement architectural elements of your home. These small details make a big difference in creating a walkway that feels custom-designed rather than cookie-cutter.

Scientific research on joint stabilization confirms what we’ve seen in our decades of experience: proper installation techniques not only improve appearance but significantly extend the lifespan of your investment.

Step 5: Seal, Maintain, Repair & Upgrade

The journey of walkway installation doesn’t end once the last paver is set. The true secret to a lasting walkway lies in how you care for it afterward. At Gerrior Masonry, we’ve seen properly maintained walkways remain beautiful for generations, while neglected ones deteriorate prematurely.

Sealing your walkway isn’t mandatory, but it’s like adding insurance to your investment. A quality poly-sealant does wonders by enhancing colors, creating stain resistance, and providing protection against harsh New England freeze-thaw cycles. The sealant also helps lock in your polymeric sand and keeps those pesky weeds from taking root between your pavers.

Timing matters when applying sealants. For new concrete or mortared installations, patience pays off—wait at least 30 days before sealing to allow proper curing. With polymeric sand installations, you’ll typically wait just 24-48 hours (always check your specific sand manufacturer’s recommendations).

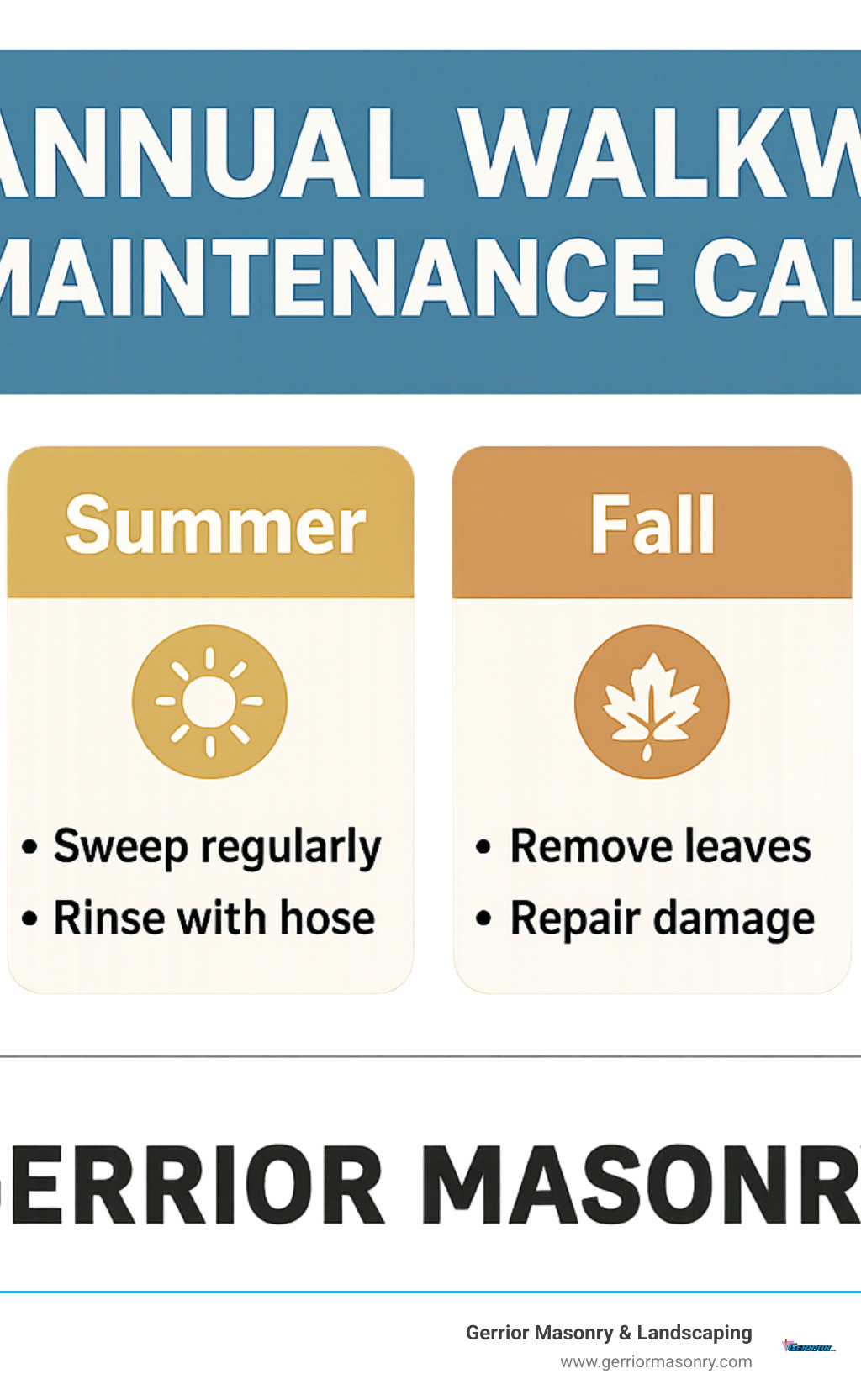

Your walkway needs regular attention to stay in top shape. I recommend creating a simple maintenance routine: sweep debris weekly, especially in fall when leaves collect; rinse occasionally with a garden hose to remove dirt; and inspect joints annually, adding fresh polymeric sand every 2-3 years as needed. Don’t forget to trim back adjacent plants that might encroach on your walkway’s borders, and promptly remove any weeds that manage to sprout.

Even the best walkways eventually need repairs, but don’t worry—most fixes are straightforward:

- Got a cracked or damaged paver? Simply remove and replace just that piece without disturbing the entire walkway.

- Notice a low spot collecting water? Lift those pavers, add base material to correct the grade, and reset.

- Dealing with stubborn stains? Use cleaners specifically formulated for your material type—what works for concrete might damage natural stone.

Looking to refresh your walkway’s appearance? Consider some simple upgrades that make a big impact. Solar lighting along the edges adds safety and ambiance for evening strolls. Creating landscape beds as borders brings color and texture that change with the seasons. Even something as simple as refreshing your edging materials or adding decorative potted plants at entrances can transform your walkway’s character.

The reward for proper care is impressive longevity. Throughout my years in the masonry business, I’ve seen well-installed paver walkways perform beautifully for over 50 years, while natural stone installations often become family heirlooms, lasting a century or more with minimal intervention.

More info about DIY Paver Walkway

Frequently Asked Questions about Walkway Installation

How many pavers do I need?

One of the most common questions we hear at job sites is about paver quantities. The math isn’t complicated, but getting it right saves both money and frustrating mid-project supply runs.

To calculate how many pavers you’ll need, start by measuring your total square footage (length × width). Then divide by the square footage of a single paver. Finally—and this is crucial—add that extra 10% for cuts and waste.

Let me walk you through a real example: For a standard 3′ × 20′ walkway, you’re looking at 60 square feet total. If you’re using 12″ × 12″ pavers (1 sq ft each), you’ll need approximately 66 pavers (60 ÷ 1 × 1.10).

Things get trickier with herringbone patterns or mixed-size pavers. In these cases, online calculators can be lifesavers, or you can always give us a call—we’re happy to help with the math!

Is concrete cheaper than pavers?

Yes, concrete is typically cheaper upfront—there’s no getting around that fact. A basic concrete walkway runs about $6-$10 per square foot installed, while pavers generally range from $10-$30 per square foot installed.

But here’s what my 34+ years in masonry has taught me about true value: The long-term economics often favor pavers for several reasons:

- Longevity: Pavers typically last 50-100 years compared to concrete’s 25-50 years

- Repair simplicity: When a paver cracks, you replace just that paver. When concrete cracks, the repair is almost always visible

- Utility access: Pavers can be removed and reinstalled if you need to access something underneath

- Home value: Pavers typically add more resale value to your property

I’ve seen countless homeowners who initially chose concrete for the savings come back years later for a paver replacement. When you consider lifetime cost and hassle, pavers often win the economic argument despite the higher initial price tag.

How long does a professional vs DIY project take?

Time is one resource you can’t get back, so this question matters a lot. Here’s the honest breakdown:

When my crew at Gerrior Masonry tackles a walkway installation, we typically complete projects on this timeline:

– Small walkway (under 100 sq ft): 1-2 days

– Medium walkway (100-300 sq ft): 2-3 days

– Large or complex walkway: 3-5 days

For DIY enthusiasts, the same projects typically take:

– Small walkway: 2-4 days (working weekends)

– Medium walkway: 1-2 weeks (working weekends)

– Large or complex walkway: 2+ weeks (working weekends)

Why the big difference? It’s not just experience (though that helps!). Professionals have specialized equipment (like commercial-grade plate compactors), coordinated crews who work together efficiently, and the benefit of having overcome every possible installation challenge dozens of times before.

That said, many homeowners find tremendous satisfaction in DIY projects. Just be realistic about your timeline, especially if you’re working solo or only on weekends.

Gerrior Masonry & Landscape Construction, based in Woburn MA, proudly serves homeowners across Middlesex and Essex County with high-quality walkway, patio, and hardscape solutions.

Conclusion

Congratulations! You’ve now explored the complete roadmap to walkway installation success. From the initial sketches to the final polymeric sand sweep, each step contributes to creating a pathway that not only improves your property’s beauty but stands the test of time.

A well-executed walkway is truly an investment in your home. While the process might seem intensive, the rewards are substantial: improved curb appeal, increased safety, better accessibility, and a lasting outdoor feature that serves your family for decades.

The average prices we’ve discussed throughout this guide reflect industry-wide estimates gathered from various sources. Your actual costs may vary significantly based on your specific location, property conditions, material selections, and design complexity. For Massachusetts homeowners, factors like soil type, slope considerations, and local material availability can all influence your final investment.

Looking back at your journey, you’ve learned how proper base preparation makes all the difference between a walkway that lasts five years versus fifty. You’ve finded how material choices balance initial costs against lifetime value. And you’ve seen how thoughtful design decisions transform a simple path into an architectural feature that complements your home.

Ready to bring your walkway vision to life? Whether you’re a confident DIYer with a weekend project ahead or a homeowner seeking professional expertise, the path forward is clear. For those who prefer the assurance of professional installation with decades of experience behind it, we’re always here to help.

More info about installing a paver walkway

Gerrior Masonry & Landscape Construction, based in Woburn MA, proudly serves homeowners across Middlesex and Essex County with high-quality walkway, patio, and hardscape solutions. With over three decades of changing Massachusetts properties, we bring craftsmanship, attention to detail, and local expertise to every walkway installation project we undertake.